Deformation-resistant optics reflecting film, liquid crystal display device and LED lighting equipment

An optical reflection, anti-deformation technology, applied in lighting and heating equipment, optics, reflectors, etc., can solve the problems of easy deformation, high cost, complex manufacturing process, etc., to improve deformation resistance, high deformation resistance, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: Preparation of Optical Reflective Film 1

[0059] (1) Size: 750mm×450mm

[0060] (2) Material: The reflective layer is a PET white film with a microporous structure inside, with a thickness of 35 μm and a thermal expansion coefficient of 2.0×10 -5 / K, the anti-deformation layer is an ordinary PS film with a thickness of 7 μm and a thermal expansion coefficient of 4.0×10 -5 / K.

[0061] (3) Preparation: Use a polyurethane system adhesive (PC5000, Guangzhou Nippon Paint Co., Ltd.) to bond the anti-deformation layer film and the back of the reflective layer film to each other, and then heat the bonded film at 100°C for 3 minutes to make It was cured to obtain the optical reflection film 1 of the present invention.

Embodiment 2

[0062] Embodiment 2: Preparation of Optical Reflective Film 2

[0063] (1) Size: 750mm×450mm

[0064] (2) Material: The reflective layer is a PET white film with a microporous structure inside, with a thickness of 35 μm and a thermal expansion coefficient of 2.5×10 -5 / K, the anti-deformation layer is an ordinary PET film with a thickness of 15 μm and a thermal expansion coefficient of 3.0×10 -5 / K.

[0065] (3) Preparation: Use polyurethane system adhesive (PC2000, Guangzhou Nippon Paint Co., Ltd.) to bond the anti-deformation layer film and the back of the reflective layer film to each other, and then heat the bonded film at 100°C for 3 minutes to make It was cured to obtain the optical reflective film 2 of the present invention.

Embodiment 3

[0066] Embodiment 3: Preparation of Optical Reflective Film 3

[0067] (1) Size: 750mm×450mm

[0068] (2) Material: The reflective layer is a PET white film with a microporous structure inside, with a thickness of 35 μm and a thermal expansion coefficient of 2.7×10 -5 / K, the anti-deformation layer is ordinary PS tape, the thickness is 25μm, and the thermal expansion coefficient is 5.2×10 -5 / K.

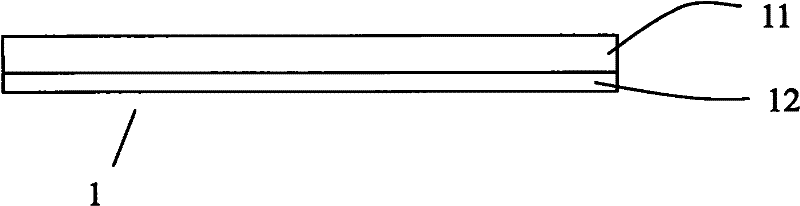

[0069] (3) Preparation: the back side of the anti-deformation layer adhesive tape and the reflective layer film are bonded to each other (such as figure 1 Shown), obtain the optical reflective film 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com