Corrosion resistant, antipollution paint for solar glass mirror face and preparation thereof

A technology of solar glass and corrosion resistance, which is applied in the field of anti-corrosion of glass mirrors, anti-pollution coatings and their preparation, and anti-corrosion of solar glass mirrors. It can solve problems affecting the reflectivity of glass mirrors, low surface activity, etc. Climate-accelerated experimental performance, improved protection capabilities, and the effect of inhibiting organic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

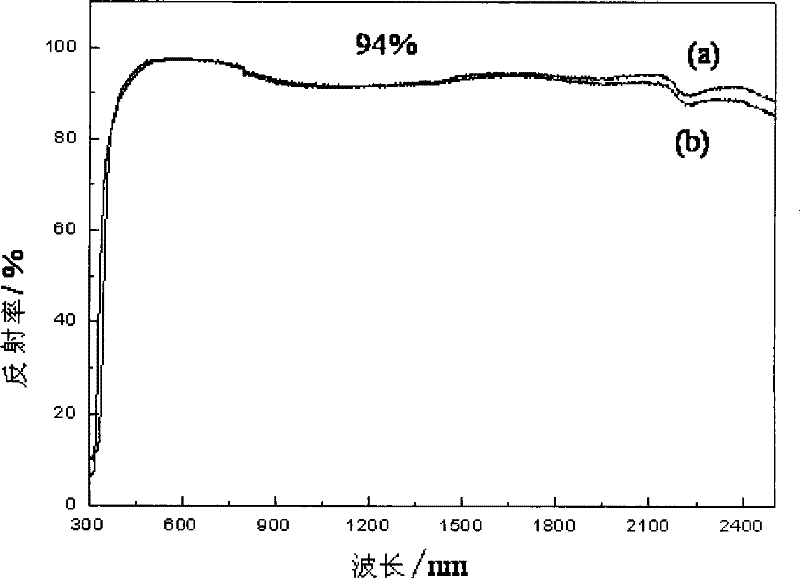

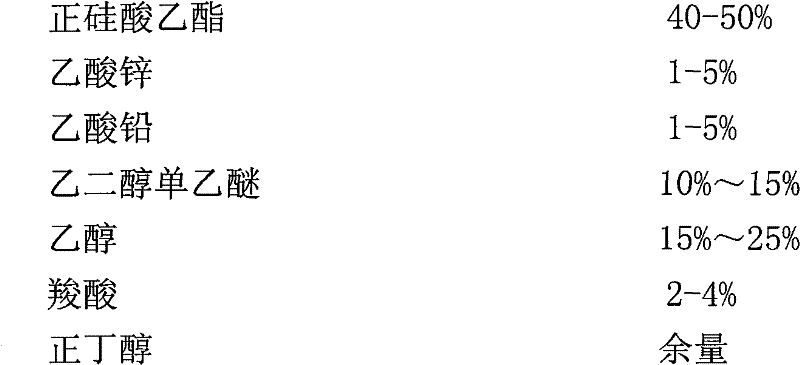

[0032] Mix zinc acetate, lead acetate, ethylene glycol monoethyl ether, and ethanol with a mass ratio of 1%, 3%, 10%, and 20% respectively to form a uniform solution, and mix at room temperature for 1 hour. Add tetraethyl orthosilicate at a mass ratio of 45% to the above solution, then add n-butanol and acetic acid at a mass ratio of 19% and 2% to the above solution, and mix the above solution for 4 hours. The obtained coating was applied to the surface of the silver-coated glass mirror, and the measured reflectance is shown in Table 1.

Embodiment 2

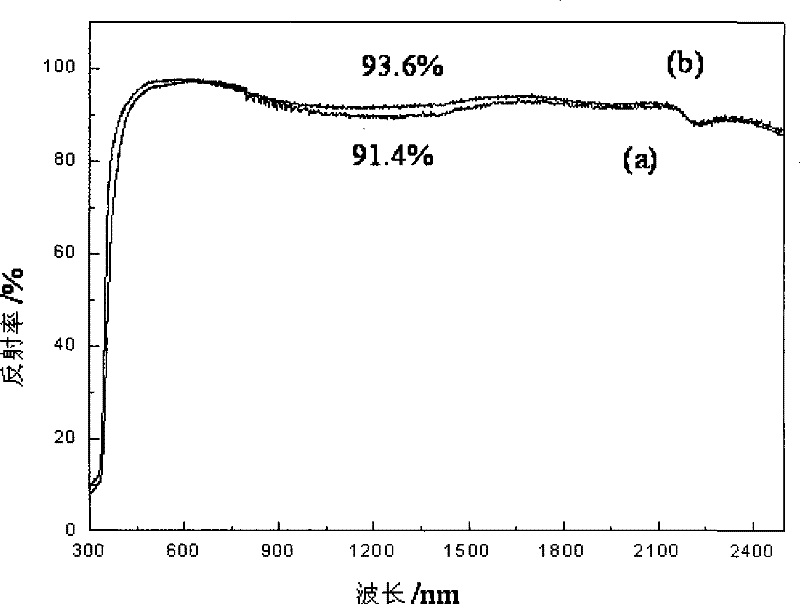

[0034] Mix zinc acetate, lead acetate, ethylene glycol monoethyl ether, and ethanol with a mass ratio of 3%, 1%, 10%, and 20% respectively to form a uniform solution, and mix at room temperature for 1 hour. Add tetraethyl orthosilicate with a mass ratio of 45% to the above solution, and then add 20% and 1% n-butanol and formic acid to the above solution, and mix the above solution for 4 hours. The obtained coating was applied to the surface of the silver-coated glass mirror, and the measured reflectance is shown in Table 1.

Embodiment 3

[0036] Mix zinc acetate, lead acetate, ethylene glycol monoethyl ether, and ethanol with a mass ratio of 2%, 1%, 10%, and 20% respectively to form a uniform solution, and mix at room temperature for 1 hour. 40% by mass ratio of tetraethyl orthosilicate was added to the above solution, and then 25% by mass ratio, 2% n-butanol and acetic acid were added to the above solution, and the above solution was mixed for 4 hours. The obtained coating was applied to the surface of the silver-coated glass mirror, and the measured reflectance is shown in Table 1.

[0037] Each embodiment component performance table of table 1

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com