A kind of laminated reflective film and preparation method thereof

A reflective film and lamination technology, used in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of easy brittle cracking, poor stiffness of the reflective film, etc., to reduce collapse, improve stiffness and Toughness, the effect of improving stiffness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

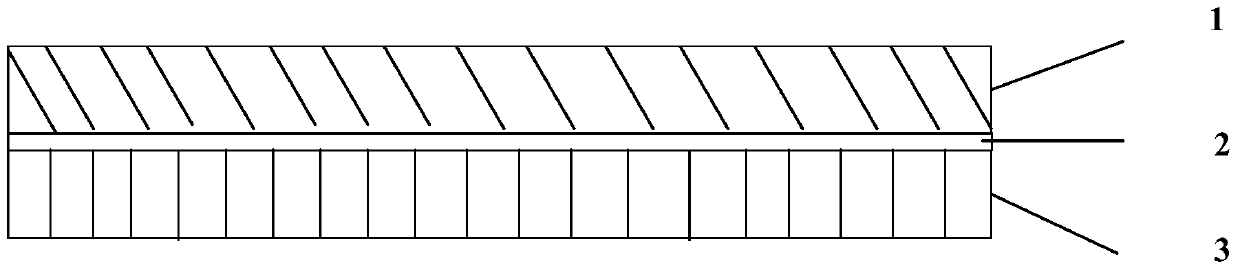

[0040] Such as figure 1 As shown, the present invention provides a bonded reflective film. The laminated reflective film includes a substrate layer 3 , a glue layer 2 and a reflective layer 1 , and the reflective layer 1 is laminated on the substrate layer 3 through the glue layer 2 .

[0041] The reflective layer is an ABA three-layer structure, the A layer is composed of polyester resin and inorganic particles, the ratio of the A layer is 98% PET chips, 2% silica particles; the B layer is composed of polyester resin, Composed of inorganic particles, incompatible resins, toughening resins, chain extenders, nucleating agents and dispersants, the ratio of layer B is 74% PEN chips, the intrinsic viscosity of PEN chips is 0.80dL / g, 10% alumina particles , 10% polyethylene, 3% MAH grafted LDPE (grafting rate ≥ 0.5%), 1% polycarbodiimide, 1% NA-10 (Japan Asahi Denka), 1% PEG (molecular weight 50000), the The percentages are percentages by weight. Wherein, the thickness of a laye...

Embodiment 2

[0047] As in the laminated reflective film provided in Example 1, the thickness of the substrate layer is 100 microns.

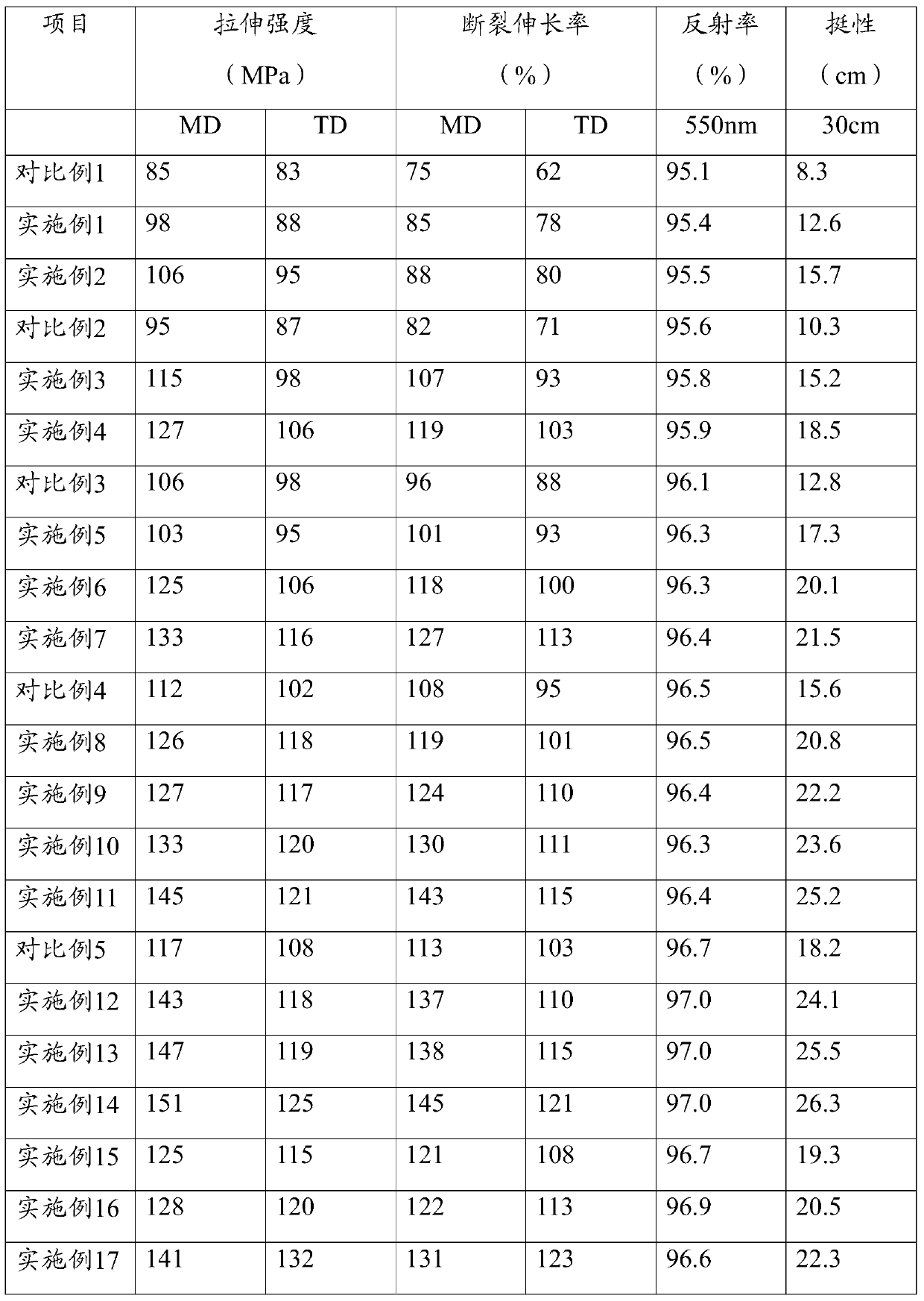

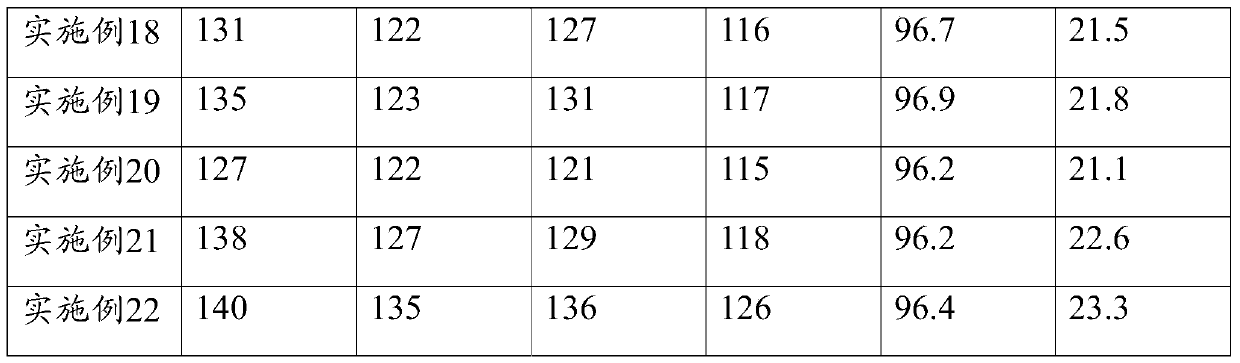

[0048] See Table 1 for the related properties of the laminated reflective film provided in Example 2.

Embodiment 3

[0050] As in the laminated reflective film provided in Example 1, wherein the proportion of the reflective layer A layer is 96% PET slices, 4% silicon dioxide particles; the proportion of B layer is 72% PEN slices, and the intrinsic viscosity of the PEN slices is 0.80dL / g, 11% alumina particles, 11% polyethylene, 3% MAH grafted LDPE (grafting rate ≥ 0.5%), 1% polycarbodiimide, 1% NA-10 (Japan Asahi Denka), 1% PEG (molecular weight: 40,000), the percentage is by weight. Wherein, the thickness of a layer A accounts for 10% of the total thickness of the reflective layer, and the thickness of the B layer accounts for 80% of the total thickness of the reflective layer. The reflective layer has a thickness of 150 microns.

[0051] The substrate layer is a PET material with a thickness of 50 microns;

[0052] See Table 1 for the related properties of the bonded reflective film provided in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com