Device and method for drying metal-based porous gel film

A gel film and drying technology, which is applied in drying gas arrangement, lighting and heating equipment, local stirring dryer, etc., can solve the problems of high efficiency and low energy consumption, achieve high efficiency, low energy consumption, and improve drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

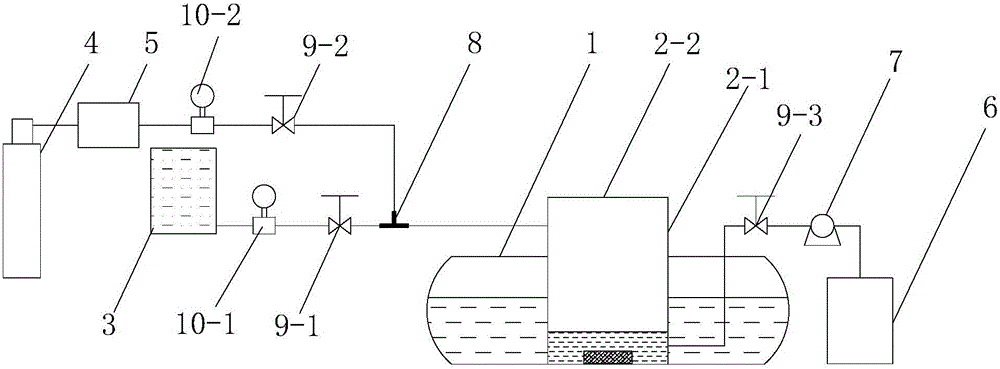

[0035] Such as figure 1 As shown, the equipment for drying the metal-based porous gel membrane of the present invention includes a constant temperature heater 1 and a drying tank, and the drying tank includes a tank body 2-1 with an open top and a cover with a movable cover arranged on the tank body 2-1 2-2, the lower part of the tank body 2-1 is located in the constant temperature heater 1, the upper part of one side of the tank body 2-1 is provided with a feed port, and the lower part of the other side of the tank body 2-1 is opened There is a discharge port, the feed port is connected to the first communication port of the three-way pipe fitting 8, the second communication port of the three-way pipe fitting 8 is connected to the heating tank 3, and the third communication port of the three-way pipe fitting 8 It is connected with the heater 5, the heater 5 is connected with the inert gas bottle 4, the discharge port is connected with the transfer pump 7, and the transfer pum...

Embodiment 2

[0041] combine figure 1 , the present embodiment utilizes the method for drying the metal-based porous gel membrane as described in Example 1, comprising the following steps:

[0042] Step 1. First, under the condition that the first valve 9-1, the second valve 9-2 and the third valve 9-3 are all closed, feed the heat transfer medium into the constant temperature heater 1, and then open the cover 2-2 Put the metal-based porous gel membrane into the tank 2-1, cover the lid 2-2, and use the heat transfer medium in the constant temperature heater 1 to heat the metal-based porous gel membrane to a constant temperature of 35°C, and then open Cover 2-2, add solvent A to tank 2-1, cover cover 2-2, make solvent A replace the original solvent remaining in the metal-based porous gel membrane, and the replacement time is 20min; the solvent A is a mixed solution, which is uniformly mixed with ethanol by any one or more of kerosene, diesel oil, glycerin, stearic acid, polyethylene glycol ...

Embodiment 3

[0045] combine figure 1 , the present embodiment utilizes the method for drying the metal-based porous gel membrane as described in Example 1, comprising the following steps:

[0046] Step 1. First, under the condition that the first valve 9-1, the second valve 9-2 and the third valve 9-3 are all closed, feed the heat transfer medium into the constant temperature heater 1, and then open the cover 2-2 Put the metal-based porous gel membrane into the tank 2-1, cover the lid 2-2, and use the heat transfer medium in the constant temperature heater 1 to heat the metal-based porous gel membrane to a constant temperature of 35°C, and then open Cover 2-2, add solvent A to tank 2-1, cover cover 2-2, make solvent A replace the original solvent remaining in the metal-based porous gel membrane, and the replacement time is 30min; the solvent A is a mixed solution, which is uniformly mixed with ethanol by any one or more of kerosene, diesel oil, glycerol, stearic acid, polyethylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com