Tail cylinder sealing piece

A technology of seals and tailpieces, applied to engine components, leakage prevention, machines/engines, etc., can solve the problems of damage or deformation, high cost, etc., and achieve the effects of reducing production costs, simple manufacturing methods, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

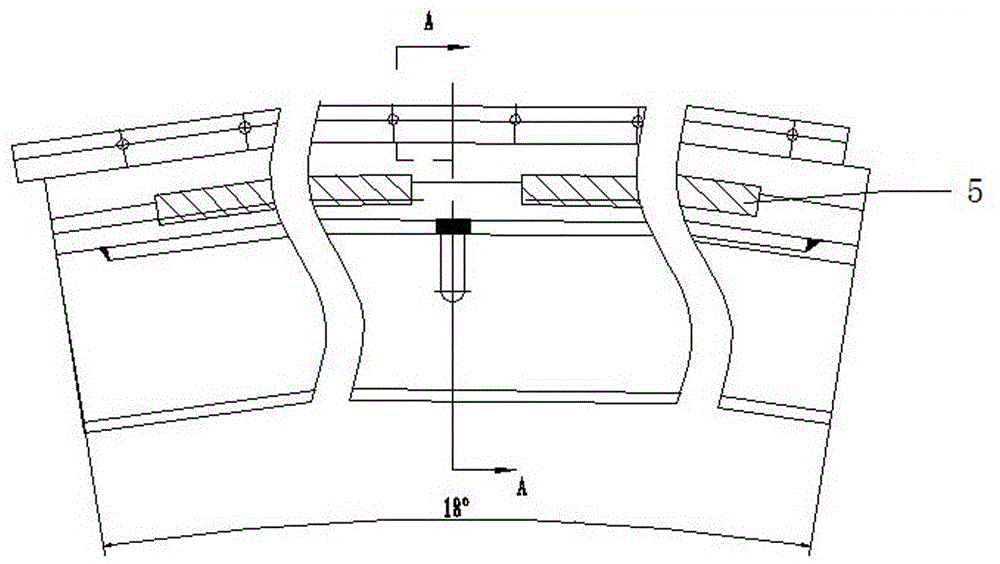

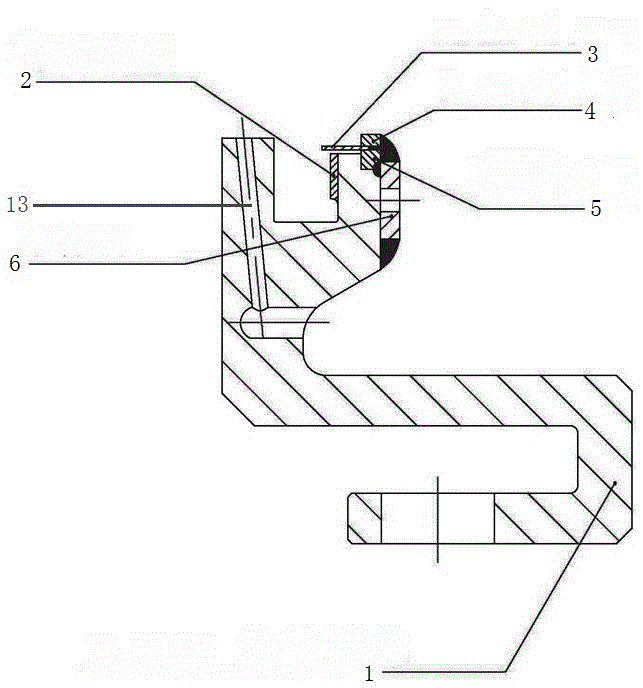

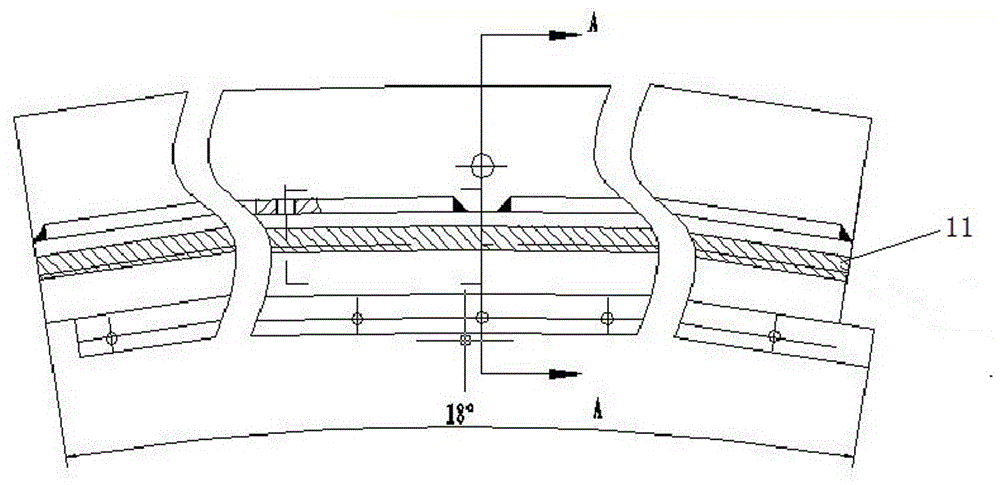

[0025] Such as Figure 1-Figure 4 As shown, a tailpiece seal includes a sealing inner ring and an outer ring, the inner ring includes an inner ring main body 1, a first brush assembly and a first welding plate 6, and the inner ring main body 1 is provided with There is a first sealing groove.

[0026] The first sealing groove includes a first groove edge and a second groove edge; the height of the first groove edge is higher than that of the second groove edge; the inner wall of the second groove edge is provided with a first sealing groove resistant Grinding plate 2.

[0027] The first brush assembly includes a first fixing plate 4, a second fixing plate 5 and a first brush sealing wire 3; the connection between the three is welding; the first brush sealing wire 3 is welded on top of the second trough side;

[0028] The first welding plate 6 is welded on the outer wall of the second groove.

[0029] The outer ring includes an outer ring main body 7, a second brush assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com