UV (ultraviolet) color change resistant environment-friendly dye paste and preparation method thereof

An environmentally friendly technology for dye paste, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of discoloration of jammed paper, restrictions on the promotion and development of environmentally friendly dye paste, and poor anti-UV discoloration ability of non-heavy metal complex dye paste. No dust pollution, wide range of application, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

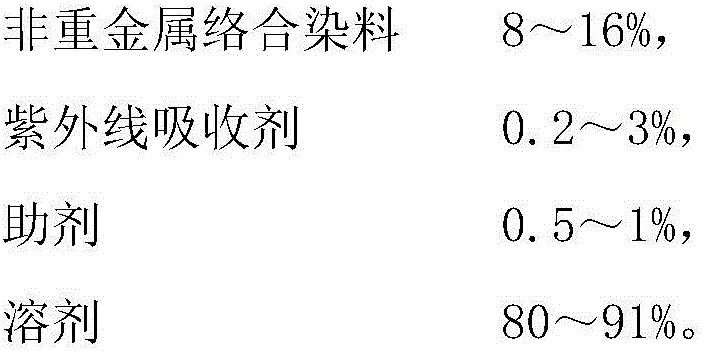

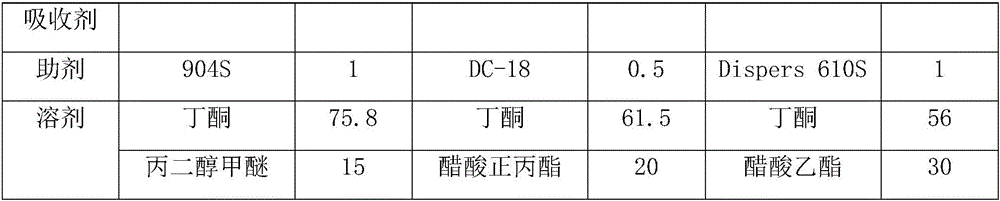

[0030] The present examples 1-3 relate to an environment-friendly dye slurry that resists UV discoloration, and its corresponding components and weight percentages are shown in Table 1.

[0031] The preparation method of the environment-friendly dye paste of anti-UV discoloration of the present embodiment 1~3 comprises the following steps:

[0032] (1) Put all the solvents into the reaction kettle according to the formula components, and stir evenly;

[0033] (2) Put the ultraviolet absorber and auxiliary agent into the reaction kettle under stirring state, and fully stir;

[0034] (3) Put the non-heavy metal complex dye powder into the reaction kettle according to the formula components, and fully stir until the dye powder is completely dissolved;

[0035] (5) Measure the solid content and color concentration, and adjust to the theoretical value;

[0036] (6) Stir again slowly for 0.5h, filter with 320-mesh filter cloth and weigh and pack.

[0037] Table 1

[0038]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com