VOC remover of composite fabric for vehicles

A technology of composite fabrics and removers, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve problems such as strong toxicity, and achieve the effect of strong applicability, good removal ability, and excellent VOC removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

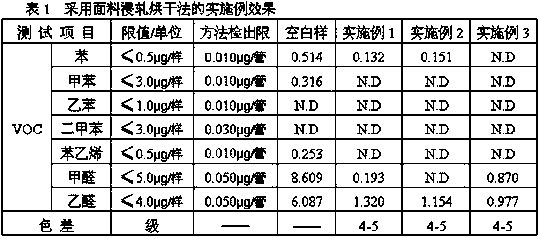

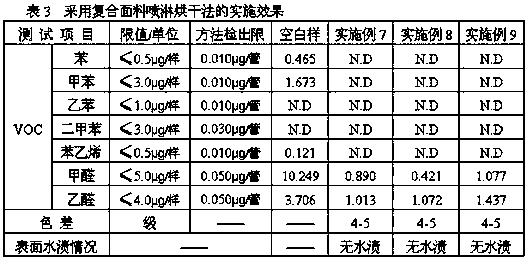

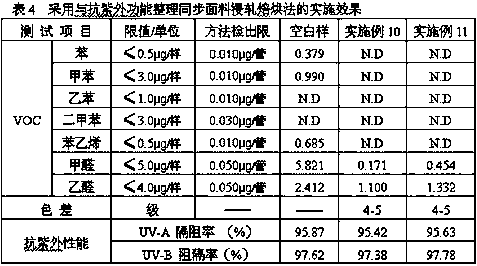

Examples

Embodiment 1

[0041] A VOC remover for composite fabrics for vehicles, which is added in the reaction kettle in sequence according to the weight ratio and order of the following raw materials, and is prepared under stirring conditions:

[0042]First add 73% water, 10% N-(2-aminoethyl)-1,3-propanediamine, 3% succinimide and PEG-200: 2% to the reactor in order, and stir evenly , slowly add in sequence: 4% butane tetracarboxylic acid, 1% maleic acid and 1% 2,3-dihydroxysuccinic acid. After the addition is completed, continue to stir for 20 minutes at room temperature, and then add 1% oleyl alcohol Polyoxyethylene ether OV-10 and 0.5% fatty alcohol polyoxyalkyl ether are used as emulsifying and dispersing agents, stirred to make it a stable and uniform solution, and finally 1.5% ammonium sulfate is added as a pH buffer regulator, and stirred evenly to prepare Taste.

[0043] The VOC remover product produced in this example is a colorless transparent liquid with a specific gravity of 1.082 g / ml...

Embodiment 2

[0046] A kind of VOC remover of composite fabric for automobiles, similar to Example 1, according to the weight ratio and order of the following raw materials, prepared under stirring conditions:

[0047] Add water 69.5%, N,N'-bis(3-aminopropyl) ethylenediamine 10%, polyacrylamide 3%, PEG-200: 8% in sequence in the reaction kettle, stir well, then slowly add butane Tetracarboxylic acid 5%, continue to stir after the addition is complete, react at room temperature for 20 minutes, then add 3% isomeric tridecanol polyoxyethylene ether E-1308 as an emulsifying dispersant, stir to make it a stable and uniform solution, and finally add 1.5 % ammonium sulfate is used as a pH buffer regulator, and it is evenly stirred. It is a VOC remover product for automotive composite fabrics.

[0048] The product of this example is a light yellow transparent liquid with a specific gravity of 1.09 g / ml at room temperature (25°C) and a pH value of 6.4. Product packaging can be packaged in industria...

Embodiment 3

[0051] A kind of VOC remover of composite fabric for automobiles, similar to Example 1, according to the weight ratio and order of the following raw materials, prepared under stirring conditions:

[0052] Add water 59.5%, N-(2-aminoethyl)-1,3-propanediamine 5%, N,N'-bis(3-aminopropyl)ethylenediamine 6%, urea 3%, N-(2-aminoethyl)-1,2-ethylenediamine 3%, succinimide 6% and PEG-200: 5%, after stirring evenly, slowly add butane tetracarboxylic acid 10 %, after the feeding is completed, continue to stir and react at room temperature for 30 minutes, then add 0.5% oleyl alcohol polyoxyethylene ether OV-20 and 0.5% isomeric tridecyl alcohol polyoxyethylene ether E-1306 as emulsifying dispersant, stir to make it Become a stable and uniform solution, and finally add 1.5% ammonium sulfate as a pH buffer regulator, stir evenly, and obtain the product.

[0053] The VOC remover product for automotive composite fabrics is a light yellow transparent liquid with a specific gravity of 1.112 g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com