Heat exchanger for low-temperature air source heat pump water module and manufacturing method of heat exchanger

A low-temperature air and source heat pump technology, applied in the field of heat exchanger manufacturing, can solve the problems of uneven heating and cooling effect, average life of the hot water exchange pipe, liquid leakage, etc., and achieve uniform heating and cooling effect and heat exchange effect. Excellent, increased residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

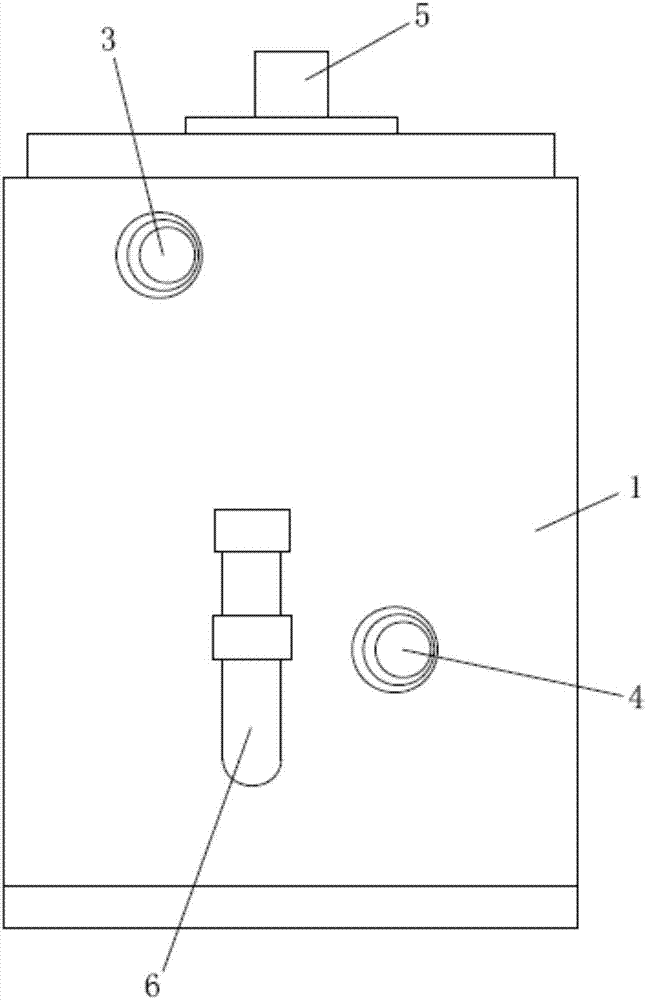

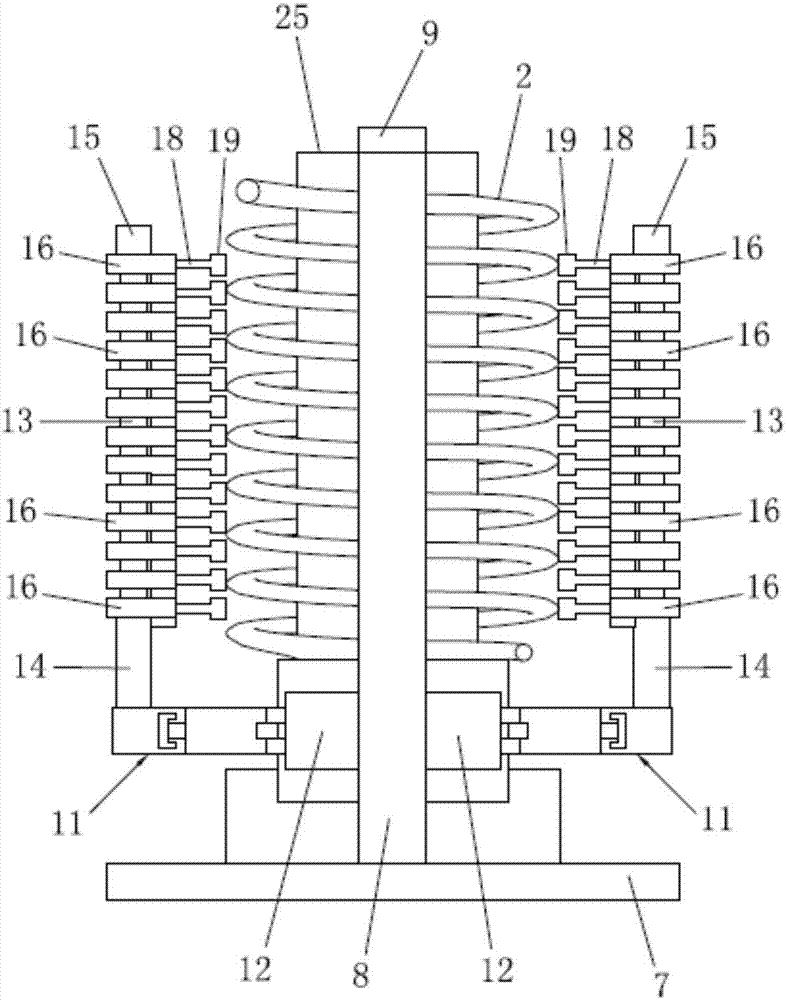

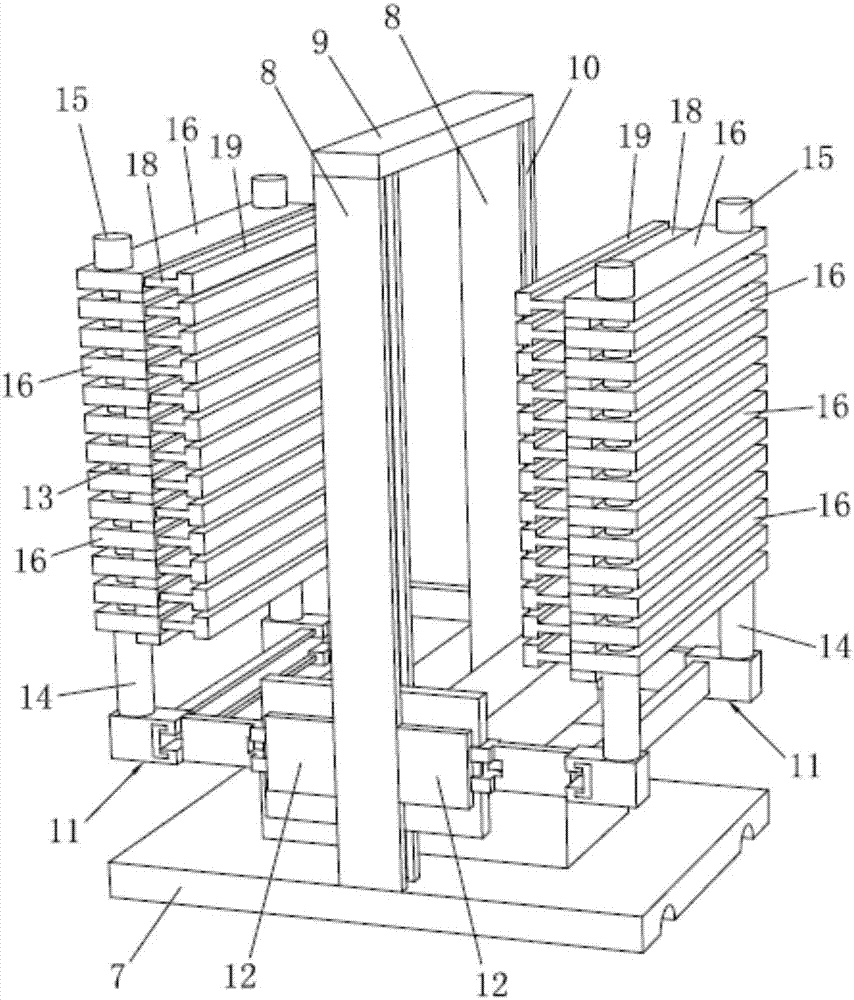

[0040] Such as Figure 1 to Figure 8 Shown is a heat exchanger for a low-temperature air source heat pump water module in the present invention, including a tank body 1 and a water exchange pipe 2 disposed in the tank body 1 . The water exchange pipe includes an outer shell 27 and an inner shell 28. A first cavity 29 is formed between the outer shell 27 and the inner shell 28. Refrigerant is passed into the first cavity 29. The inner shell 28 is provided with a second cavity 30. The brine is passed into the second cavity 30, the design of the inner shell 28 and the outer shell 27 can strengthen the total heat exchange capacity of the serpentine spiral heat exchange tube, and the design of the first cavity 29 and the second cavity 30 can facilitate When the refrigerant and the brine are introduced, the brine absorbs the heat and then transfers it to the refrigerant, which realizes the transfer of heat and can make the brine be cooled again, so as to achieve the purpose of conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com