A method for increasing the co-production fermentation yield of s-adenosylmethionine and glutathione

A technology of adenosylmethionine and glutathione, which is applied in the field of improving the yield of SAM and GSH co-production and fermentation, can solve the problems of high price, time-consuming, and limited industrial application, and achieves the effect of promoting synthesis and accumulation and improving synthesis rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one: Utilize original bacterial strain C.utilis CCTCC M 209298 (WT) shake flask fermentation culture

[0047] The original strain C. utilis CCTCC M 209298 was inoculated into 50 mL of fermentation medium at an inoculum size of 10% (v / v), and cultured on a shaker at 30° C. at 200 rpm for 30 hours.

[0048] Determination of yeast biomass: Yeast biomass was expressed as dry cell weight (DCW). Take 10 mL of fermentation broth, centrifuge at 4000 rpm for 5 min, wash with distilled water for 3 times, collect bacteria, and dry at 70°C until constant weight.

[0049] Extraction and determination of intracellular GSH: Fresh yeast obtained by fermentation culture was washed 3 times with distilled water, treated in 40% ethanol solution at 30°C for 2 hours, centrifuged to take the supernatant as the sample to be tested. The concentration of GSH in the sample was determined by 5,5'-dithiobis(2-nitrobenzoic acid) [DTNB]-glutathione reductase cycle method.

[0050] Extrac...

Embodiment 2

[0053] Embodiment 2: Utilize mutant strain C.utilisΔPor1 (2A) shake flask fermentation culture

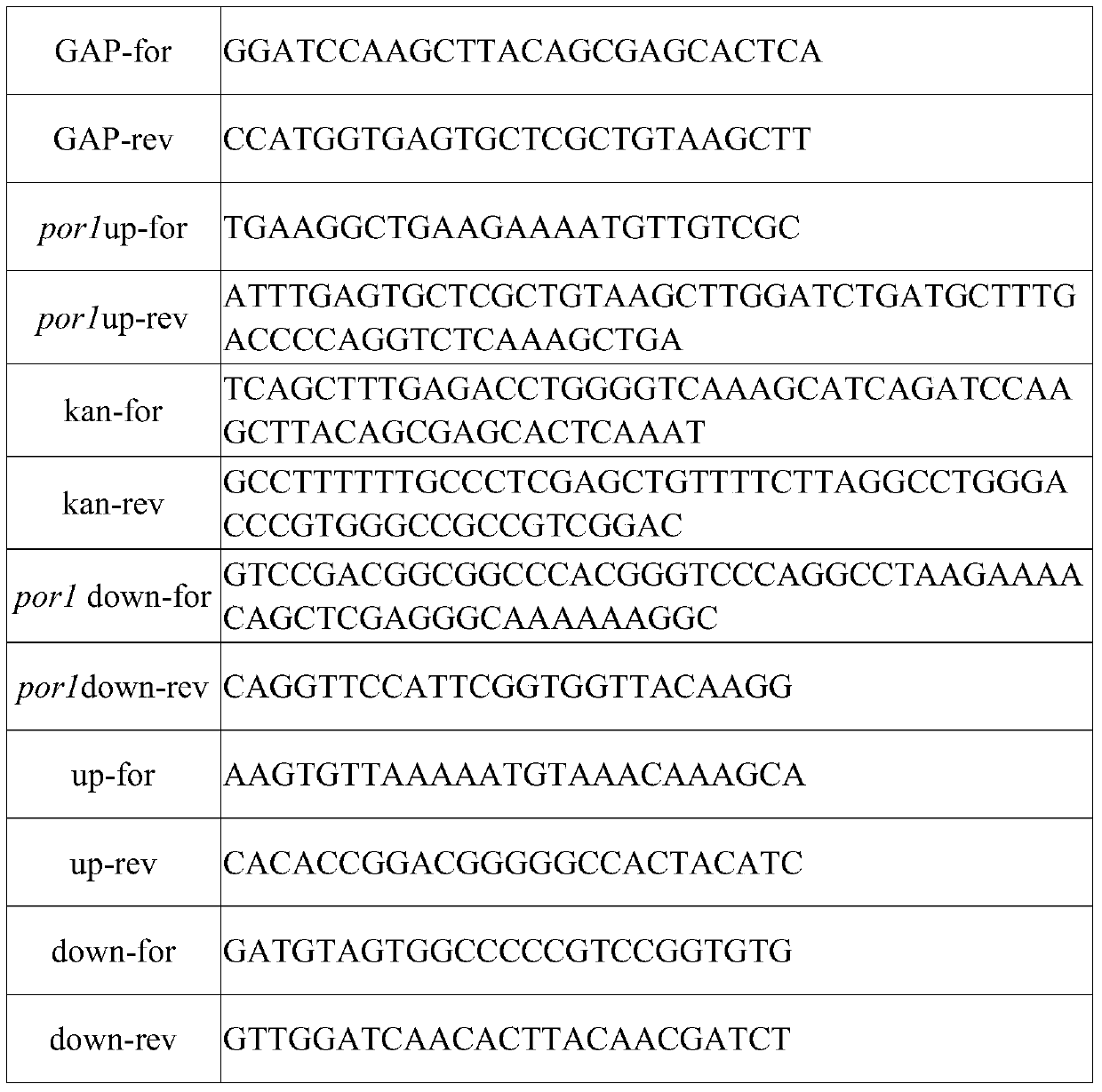

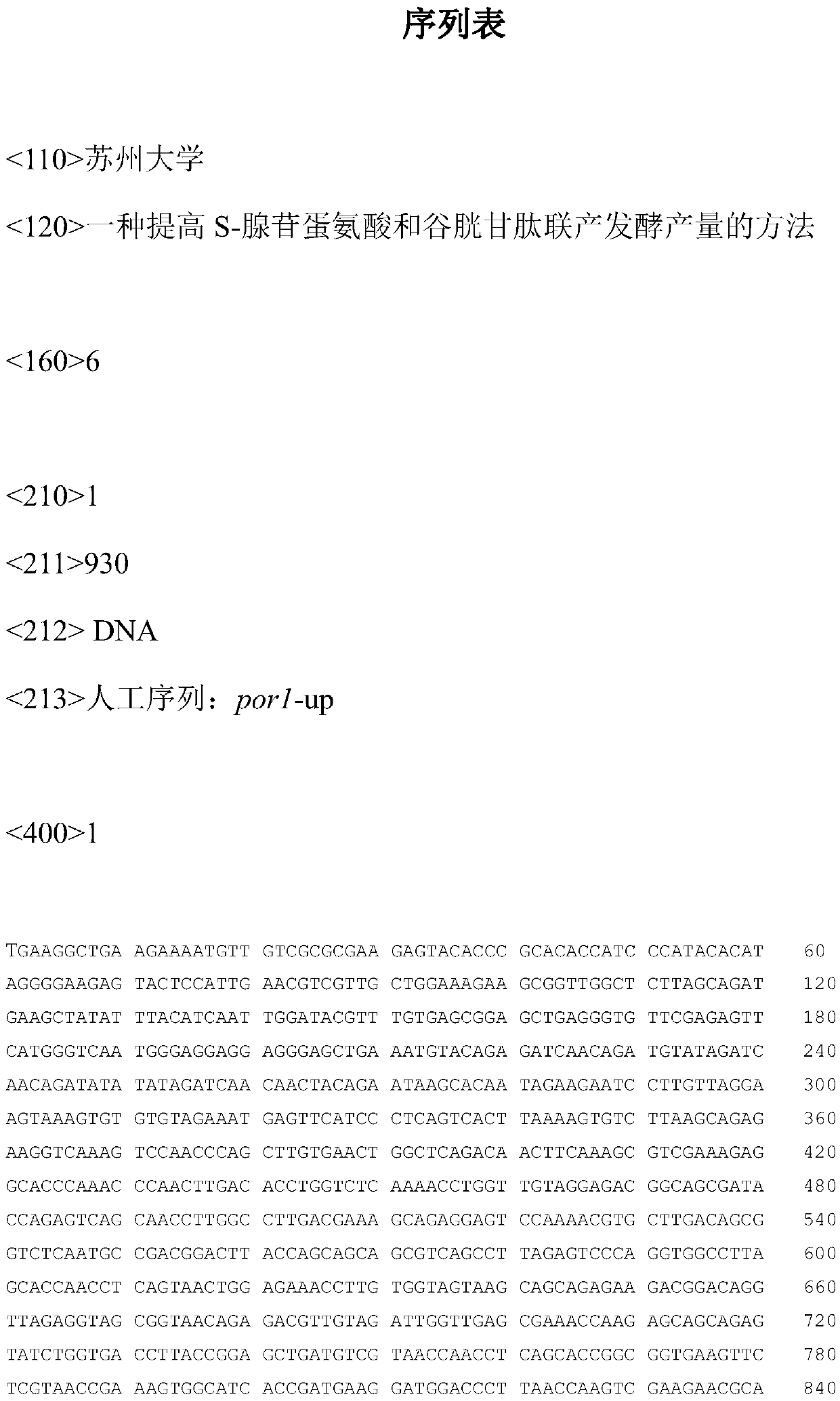

[0054] The primer sequences in the examples are shown in List 1 below:

[0055] Table 1: Primer Sequence List

[0056]

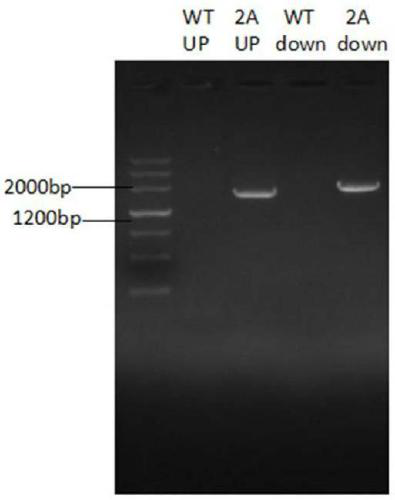

[0057] 1. Knockout of the Por1 gene on the mitochondrial membrane of Candida utilis

[0058] (1) The whole genome sequence of C.utilis was retrieved in the National Center for Biotechnology Information (NCBI) database, and the GAP promoter sequence of Saccharomyces cerevisiae was used as a template to find the GAP promoter sequence of C. Primers GAP-for, GAP-rev, using C.utilis CCTCC M 209298 genome as a template to amplify the GAP promoter sequence of C.utilis, the fragment size is about 1000bp;

[0059] (2) After the amplified GAP promoter fragment and the plasmid containing the kan gene fragment are digested, ligated, transformed, and spliced together, PCR amplification is performed using primers kan-for and kan-rev to obtain GAP -kan fragment, the fra...

Embodiment 3

[0070] Example Three: Batch Fermentation Culture Using Original Bacterial Strain C.utilis CCTCC M 209298

[0071] The original bacterial strain C.utilis CCTCC M 209298 was inoculated into a 5L fermenter (BIOTECH-5BGZ, Shanghai Baoxing Bio-Equipment Engineering Co., Ltd.) at an inoculation volume of 10% (v / v), with a liquid volume of 3 L and an inoculum volume of 10% , the temperature is 30°C, the stirring speed is 350rpm, the ventilation rate is 3L / min, the pH is 5.0, and the incubation time is 30 hours.

[0072] Using the same yeast biomass measurement, intracellular GSH extraction and determination, and intracellular SAM extraction and determination methods as in Example 1, after testing, the experimental results using the original strain batch fermentation culture:

[0073] Dry cell weight: 12.67~12.99g / L; SAM production: 184.7~194.1mg / L; GSH production: 205.8~216.9mg / L; combined production of SAM and GSH: 390.5~411.0mg / L; intracellular SAM content: 1.55-1.63%; intracellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com