Ethyl ester and furfuryl carboxylate based flame-retardant storage battery sealant and preparation method

A technology of tetrahydrofurfuryl methacrylate and dimethylaminoethyl methacrylate is applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc. Affecting material properties, poor flame retardant effect, etc., to achieve the effect of reducing the discharge of harmful substances, reducing the gap in the glue, increasing the fire resistance and heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A flame retardant battery sealant based on ethyl ester and furfuryl alcohol ester, characterized in that: it comprises A component and B component; the A component is composed of dimethylaminoethyl methacrylate, solvent, o-phenylene Dinonyl diformate, antimony trioxide, reinforcing filler, antioxidant, chlorosulfonated polyethylene; component B consists of methacrylate tetrahydrofurfuryl alcohol ester, acrylate rubber, benzyl dimethylamine, Phosphonate flame retardant plasticizer, fumed silica, solvent, BYK-066N, r-aminopropyltriethoxysilane composition; wherein the A component includes: 40-60 parts of methacrylic acid Dimethylaminoethyl ester, 20-30 parts solvent, 4-8 parts dinonyl phthalate, 10-25 parts antimony trioxide, 5-10 parts reinforcing filler, 5- 10 parts of antioxidant, 20-35 parts of chlorosulfonated polyethylene; in the B component, including: 60-80 parts of methacrylate tetrahydrofurfuryl alcohol ester, 20-30 parts of acrylate rubber , 5-15 parts of benz...

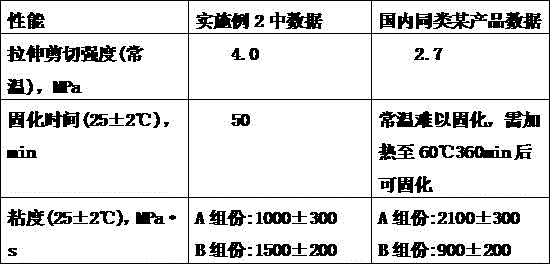

Embodiment 2

[0023] A flame retardant battery sealant based on ethyl ester and furfuryl alcohol ester, characterized in that: it comprises A component and B component; the A component is composed of dimethylaminoethyl methacrylate, solvent, o-phenylene Dinonyl diformate, antimony trioxide, reinforcing filler, antioxidant, chlorosulfonated polyethylene; component B consists of methacrylate tetrahydrofurfuryl alcohol ester, acrylate rubber, benzyl dimethylamine, Phosphonate flame retardant plasticizer, fumed silica, solvent, BYK-066N, r-aminopropyltriethoxysilane composition; wherein the A component includes: 40-60 parts of methacrylic acid Dimethylaminoethyl ester, 20-30 parts solvent, 4-8 parts dinonyl phthalate, 10-25 parts antimony trioxide, 5-10 parts reinforcing filler, 5- 10 parts of antioxidant, 20-35 parts of chlorosulfonated polyethylene; in the B component, including: 60-80 parts of methacrylate tetrahydrofurfuryl alcohol ester, 20-30 parts of acrylate rubber , 5-15 parts of benz...

Embodiment 3

[0032] The A component includes: 40-55 parts of dimethylaminoethyl methacrylate, 20-28 parts of solvent, 4-7 parts of dinonyl phthalate, 10-22 parts of It consists of antimony trioxide, 5-8 parts of reinforcing filler, 5-9 parts of antioxidant, 20-33 parts of chlorosulfonated polyethylene; the B component includes: 60-78 parts of Methacrylate tetrahydrofurfuryl alcohol ester, 20-25 parts of acrylate rubber, 5-12 parts of benzyl dimethylamine, 5-13 parts of phosphonate flame retardant plasticizer, 5-8 parts of gas phase dimethicone Silica, 25-35 parts solvent, 10-14 parts BYK-066N, 4-8 parts r-aminopropyltriethoxysilane.

[0033] The proportioning in the above-mentioned components is made by the following preparation method:

[0034] 1. In component A, dimethylaminoethyl methacrylate, solvent, dinonyl phthalate, and chlorosulfonated polyethylene are added to the vacuum kneader according to the above-mentioned proportioning method of parts by weight, at a temperature of 100 ℃,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com