Nano ATO (antimony oxide)/CuS (copper sulfide) filler type waterborne acrylic acid transparent thermal insulation coating

A technology of water-based acrylic and thermal insulation coatings, applied in the direction of radiation-absorbing coatings, coatings, etc., to achieve the effects of stable performance, good light transmission, and large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

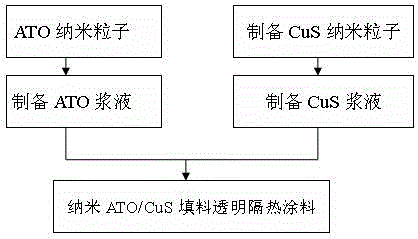

Method used

Image

Examples

Embodiment 1

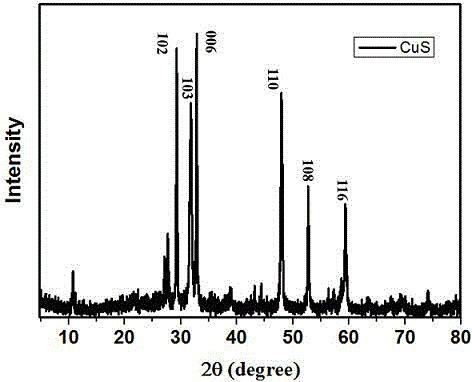

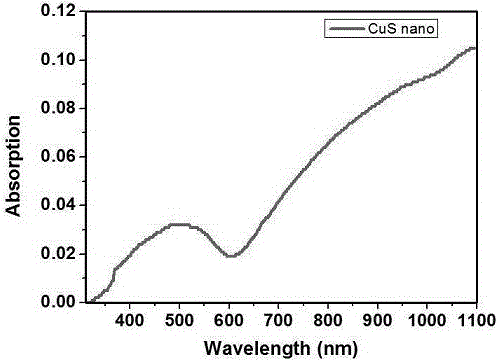

[0042] Embodiment 1: Synthesis of CuS nanoparticles

[0043] Weigh 99mg of copper acetate monohydrate and 16mg of sublimed sulfur, blend and dissolve them in 40mL of dimethyl sulfoxide solvent with ultrasonic stirring, continue magnetic stirring for 40 minutes after fully dissolving, and add to a 100 mL polytetrafluoroethylene container , and reacted at 120°C for 3 hours in a high-pressure reactor. After the reaction, cool to room temperature to obtain a colorless supernatant and a large amount of black precipitate, which is collected by high-speed centrifugation, washed with deionized water and ethanol three times, and then dried in an oven at 50°C for 2 hours to collect the black precipitate.

Embodiment 2

[0045] Preparation of nano-ATO / CuS filler waterborne acrylic transparent heat-insulating coating

[0046] (1) Prepare 8% CuS slurry:

[0047] Add 400 mg of CuS nanoparticles to 4410 mL of deionized water, then add 75 mg of KH-570 silane coupling agent, 15 mg of LH308 water-based wetting and leveling agent, and 100 mg of BYK-190 dispersant; oscillate and ultrasonically for 20 minutes until the dispersion is uniform, and then Stir magnetically for 2 hours.

[0048] (2) Preparation of 30% ATO slurry:

[0049] Add 30g of ATO nanoparticles into 66.75mL of deionized water, then add 2g of KH-570 silane coupling agent, 0.25g of LH308 water-based wetting and leveling agent, 1g of BYK-190 dispersant, oscillate and ultrasonic for 20 minutes until the dispersion is uniform, and then magnetically stir for 2 Hour.

[0050] (3) Preparation of ATO / CuS mixed slurry:

[0051] 30% ATO slurry and 8% CuS slurry were mixed according to the volume fraction of 10:1, and magnetically stirred for 2...

Embodiment 3

[0055] Preparation of Waterborne Acrylic Transparent Thermal Insulation Coatings with Nano-ATO / TiO2 Fillers for Comparative Coatings

[0056] (1) Preparation of 30% ATO slurry:

[0057] Add 30g of ATO nanoparticles into 66.75mL of deionized water, then add 2g of KH-570 silane coupling agent, 0.25g of water-based wetting and leveling agent 308, 1g of BYK-190 dispersant, oscillate and ultrasonic for 20 minutes until the dispersion is uniform, and then magnetically stir 2 hours.

[0058] (2) Preparation of 8%TiO 2 Serum:

[0059] 8gTiO 2 Add nanoparticles (particle size ≤ 15nm) into 88mL deionized water, then add 1.5g KH-570 silane coupling agent, 2g LH308 water-based wetting and leveling agent, 2g BYK-190 dispersant, oscillate and ultrasonic for 20 minutes until the dispersion is uniform, and then Stir magnetically for 2 hours.

[0060] (3) Preparation of ATO / TiO 2 Mixed slurry:

[0061] 30% ATO slurry and 8% TiO 2 The slurry was mixed according to the volume fraction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com