Air purifying putty and its preparation and use method

An air purification and putty technology, applied in filling slurry, covering/lining, construction, etc., can solve the problems of hygroscopicity and poor air purification performance, and achieve good flexibility and anti-cracking characteristics, good water retention performance, and strong adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

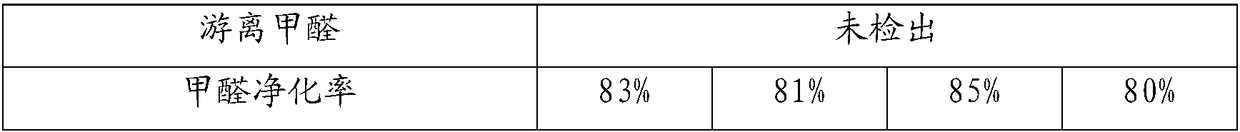

Examples

Embodiment 1

[0028] The air-purifying putty is composed of the following components: 70 parts by weight of shell powder, 10 parts by weight of heavy calcium powder, 8 parts by weight of talcum powder, 4 parts by weight of guar gum, 4 parts by weight of basalt fiber, and 1 part by weight of hydroxypropyl methylcellulose ether parts by weight, expanded vermiculite 4 parts by weight.

Embodiment 2

[0030] The air-purifying putty is composed of the following components: 50 parts by weight of shell powder, 16 parts by weight of heavy calcium powder, 15 parts by weight of talcum powder, 4 parts by weight of guar gum, 2 parts by weight of basalt fiber, and 1 part by weight of hydroxypropyl methylcellulose ether parts by weight, expanded vermiculite 5 parts by weight.

Embodiment 3

[0032] The air purification putty is composed of the following components: 60 parts by weight of shell powder, 15 parts by weight of heavy calcium powder, 10 parts by weight of talcum powder, 4 parts by weight of guar gum, 4 parts by weight of basalt fiber, 2 parts by weight of hydroxypropyl methylcellulose ether parts by weight, expanded vermiculite 3 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com