Conductive rubber composition and preparation method thereof

A technology of conductive rubber and composition, applied in the field of rubber, can solve the problems of high cost and difficulty in synthesizing fluorosilicone rubber, and achieve the effects of improving oil resistance and solvent resistance, good processing and manufacturing process performance, and low volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

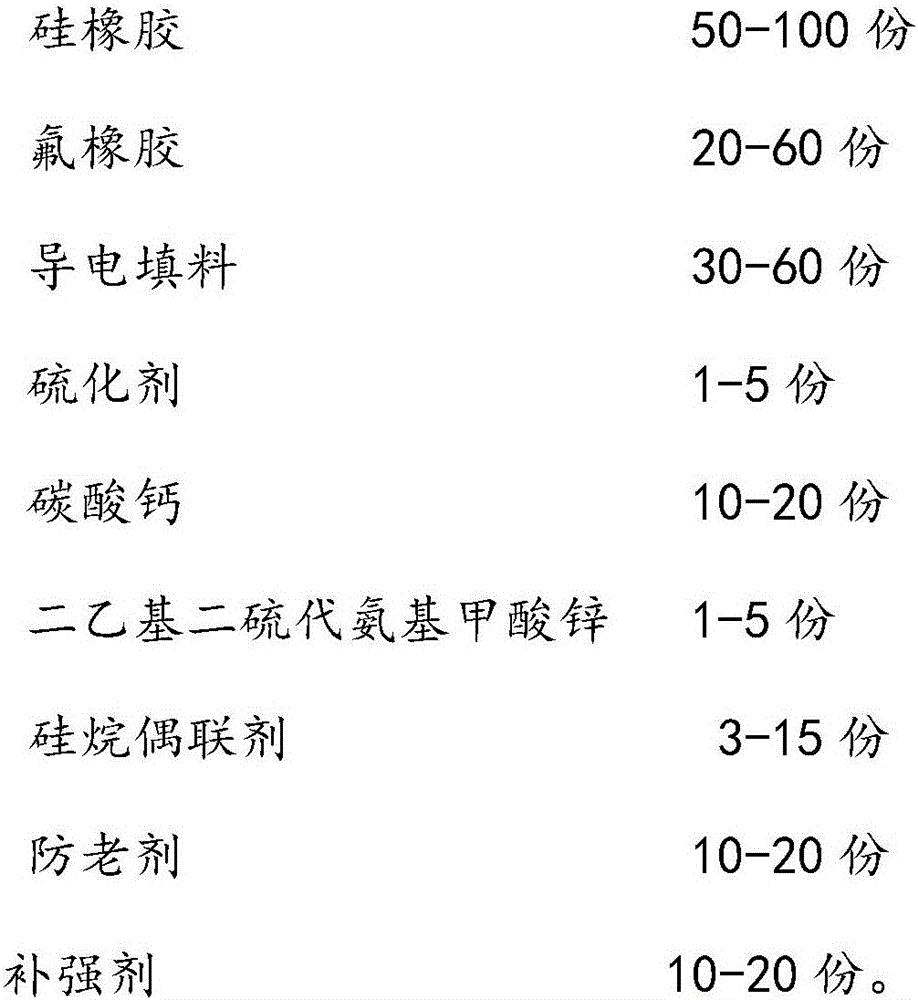

[0027] The present invention proposes a kind of conductive rubber composition, and its raw material comprises by weight:

[0028]

[0029] The reinforcing agent is carbon black, the anti-aging agent is N-phenyl-α-aniline, the vulcanizing agent is dicumyl peroxide, the silicone rubber is methyl silicone rubber, the fluororubber is polyolefin fluororubber, and the conductive filler is graphite .

[0030] The invention also discloses a preparation method of a conductive rubber composition, comprising the following steps:

[0031] Step 1: Carry out low-temperature mastication of silicone rubber and fluororubber respectively through an open mill;

[0032] Step 2: Mix the silicone rubber, fluororubber, conductive filler, anti-aging agent, reinforcing agent, calcium carbonate, zinc diethyldithiocarbamate, vulcanizing agent, and silane coupling agent after plasticizing in step 1, and mix the obtained The mixture is kneaded twice;

[0033] Step 3: park the mixture kneaded in step...

Embodiment 2

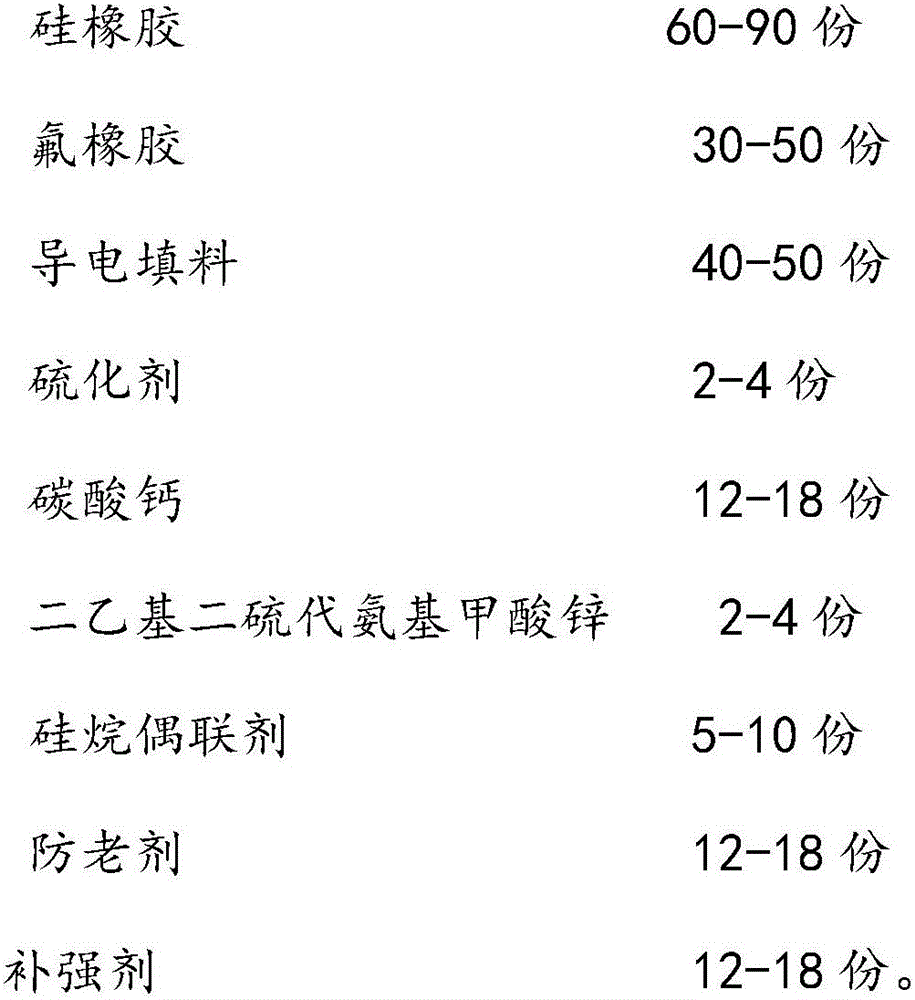

[0036] The present invention proposes a kind of conductive rubber composition, and its raw material comprises by weight:

[0037]

[0038] The reinforcing agent is carbon black, the anti-aging agent is N-phenyl-α-aniline, the vulcanizing agent is dicumyl peroxide, the silicone rubber is methyl silicone rubber, the fluororubber is polyolefin fluororubber, and the conductive filler is graphite .

[0039] The invention also discloses a preparation method of a conductive rubber composition, comprising the following steps:

[0040] Step 1: Carry out low-temperature mastication of silicone rubber and fluororubber respectively through an open mill;

[0041] Step 2: Mix the silicone rubber, fluororubber, conductive filler, anti-aging agent, reinforcing agent, calcium carbonate, zinc diethyldithiocarbamate, vulcanizing agent, and silane coupling agent after plasticizing in step 1, and mix the obtained The mixture is kneaded twice;

[0042] Step 3: park the mixture kneaded in step...

Embodiment 3

[0045] The present invention proposes a kind of conductive rubber composition, and its raw material comprises by weight:

[0046]

[0047] The reinforcing agent is carbon black, the anti-aging agent is N-phenyl-α-aniline, the vulcanizing agent is dicumyl peroxide, the silicone rubber is methyl silicone rubber, the fluororubber is polyolefin fluororubber, and the conductive filler is silver Aluminum clad.

[0048] The invention also discloses a preparation method of a conductive rubber composition, comprising the following steps:

[0049] Step 1: Carry out low-temperature mastication of silicone rubber and fluororubber respectively through an open mill;

[0050] Step 2: Mix the silicone rubber, fluororubber, conductive filler, anti-aging agent, reinforcing agent, calcium carbonate, zinc diethyldithiocarbamate, vulcanizing agent, and silane coupling agent after plasticizing in step 1, and mix the obtained The mixture is kneaded twice;

[0051] Step 3: park the mixture knea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com