Salt drainage concealed conduit containing chitosan oligosaccharide and preparation method of salt drainage concealed conduit

A technology of salt-discharging concealed pipe and chitosan oligosaccharides, which is applied in the direction of soil lifting machinery, application, agricultural machinery and tools, etc., can solve the problems of easy damage, insufficient elasticity, easy to break, etc., and achieve good antistatic and property stability Strong, high Vicat softening point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

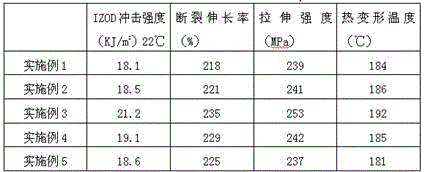

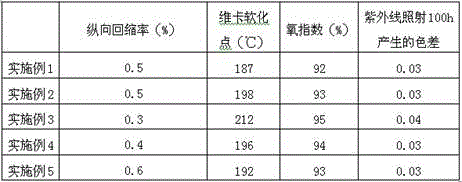

Examples

Embodiment 1

[0025] Example 1 A salt-discharging dark tube containing chitosan oligosaccharides, in parts by weight, includes the following raw materials:

[0026] 42 parts of polytetrafluoroethylene, 91 parts of high-density polyethylene, 10 parts of low-density polyethylene, 5 parts of ABS resin, 2.2 parts of chitooligosaccharides, 0.85 parts of nano silver, 1.2 parts of sorbitol, 2.3 parts of ethanolamide, solubilizer 2.4 parts, fatty acid polyol ester 0.5 parts, viscose 2.3 parts, antler bath gum powder 0.25 parts, lecithin 0.35 parts, slaked lime 0.6 parts, calcium stearate 0.45 parts, diisodecyl phthalate 0.56 parts, heal Create 1.1 parts of resin.

[0027] The said polytetrafluoroethylene has a bulk specific gravity of 360-380g / l and a molecular weight of 8500-9000;

[0028] The chitosan oligosaccharide has an average molecular weight of 1250-1262 Da and a degree of deacetylation of 92.5-93.6%;

[0029] The nano silver has a particle size of 2-3 nm and a pH value of 732-7.5;

[0030] The so...

Embodiment 2

[0034] Example 2 A salt discharge dark tube containing chitosan oligosaccharides, using the raw materials described in Example 1, only the ratio of the raw materials was changed, and changed to:

[0035] 42 parts of polytetrafluoroethylene, 91 parts of high density polyethylene, 11 parts of low density polyethylene, 6 parts of ABS resin, 2.3 parts of chitooligosaccharides, 0.85 parts of nano silver, 1.2 parts of sorbitol, 2.3 parts of ethanolamide, solubilizer 2.6 parts, fatty acid polyol ester 0.57 parts, viscose 2.3 parts, antler bath gum powder 0.25 parts, lecithin 0.35 parts, slaked lime 0.8 parts, calcium stearate 0.47 parts, diisodecyl phthalate 0.62 parts, 1.3 parts of Guaiac resin.

Embodiment 3

[0036] Example 3 A salt discharge dark tube containing chitosan oligosaccharides, using the raw materials described in Example 1, only the ratio of the raw materials was changed, and changed to:

[0037] 43 parts of polytetrafluoroethylene, 92 parts of high-density polyethylene, 11 parts of low-density polyethylene, 6 parts of ABS resin, 2.3 parts of chitooligosaccharides, 0.86 parts of nano silver, 1.3 parts of sorbitol, 2.4 parts of ethanolamide, solubilizer 2.5 parts, fatty acid polyol ester 0.6 parts, viscose 2.3 parts, staghorn bath gum powder 0.28 parts, lecithin 0.37 parts, slaked lime 0.78 parts, calcium stearate 0.46 parts, diisodecyl phthalate 0.59 parts, heal Create 1.2 parts of resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk specific gravity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com