A kind of pet film sticking method and mobile terminal

A mobile terminal and film sticking technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of adhesion tolerance and bottom penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 5 As shown, a method for attaching a PET film provided in Embodiment 1 of the present invention includes:

[0044] Step 101 , manufacturing a substrate with a predetermined size, wherein the substrate includes a first edge portion formed as an arc surface.

[0045] Firstly, a substrate with a predetermined size needs to be manufactured, where the size of the substrate can be set according to the specific size of the mobile terminal. Wherein the substrate includes a first edge portion formed as a curved surface, and when the first edge portion of the substrate is a curved surface, one side of the mobile terminal formed at this time has a curved surface structure. The substrate may also include a first edge portion formed as an arc and a second edge portion formed as an arc, wherein the first edge portion and the second edge portion are opposite, when the first edge portion and the second edge portion of the substrate are both In the case of a curved sur...

Embodiment 2

[0055] Such as Figure 8 As shown, a method for attaching a PET film provided in Embodiment 2 of the present invention includes:

[0056] Step 201 , manufacturing a substrate with a predetermined size, wherein the substrate includes a first edge portion formed as an arc surface.

[0057] Firstly, a substrate with a predetermined size needs to be manufactured, where the size of the substrate can be set according to the specific size of the mobile terminal. Wherein the substrate includes a first edge portion formed as a curved surface, and when the first edge portion of the substrate is a curved surface, one side of the mobile terminal formed at this time has a curved surface structure. The substrate may also include a first edge portion formed as an arc and a second edge portion formed as an arc, wherein the first edge portion and the second edge portion are opposite, when the first edge portion and the second edge portion of the substrate are both In the case of a curved sur...

Embodiment 3

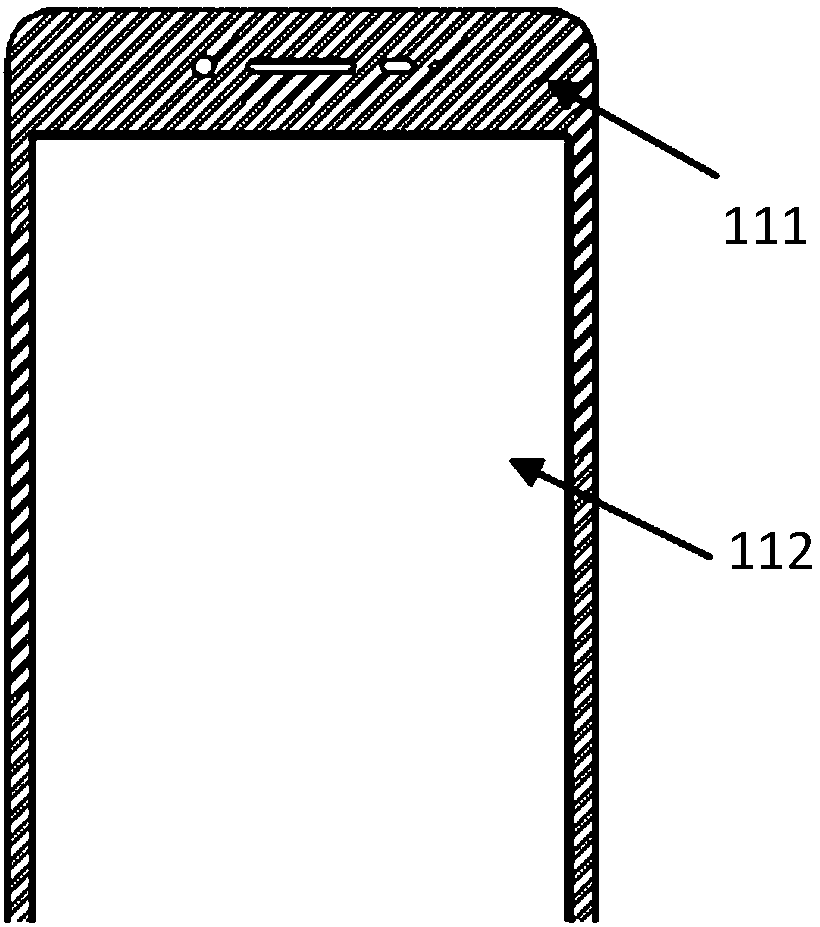

[0078] Such as Figure 7 As shown, a mobile terminal provided by Embodiment 3 of the present invention includes:

[0079] The substrate 1 includes a first edge portion 11 formed as an arc surface;

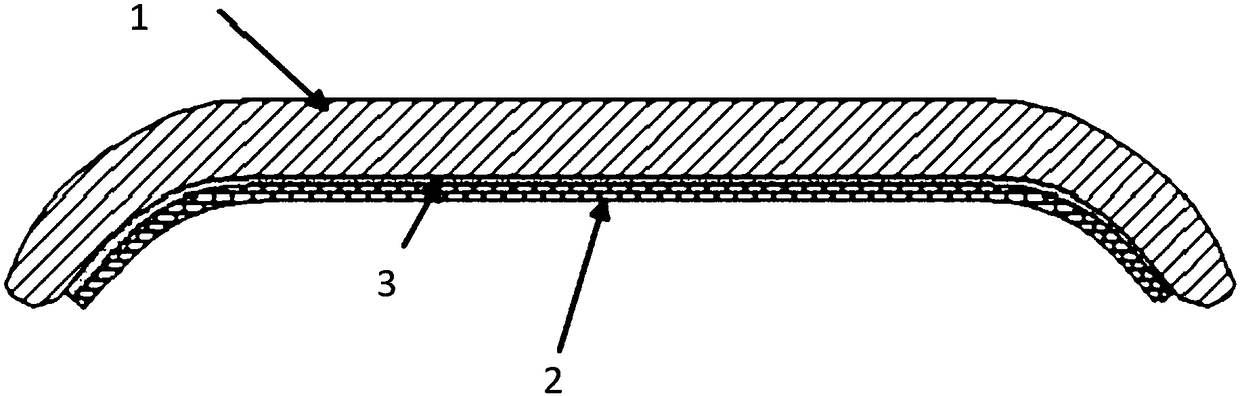

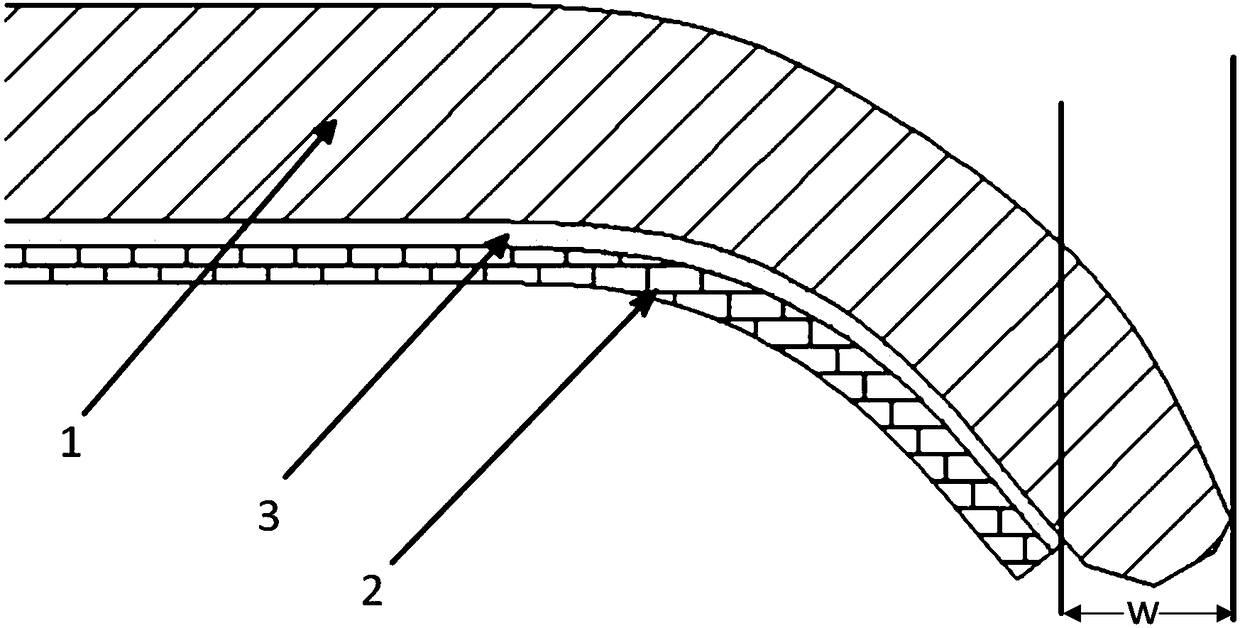

[0080] A PET film 2, the PET film 2 is attached to the first surface 13 of the substrate 1, wherein the first surface 13 is the curved inner surface of the first edge portion 11, and at the first edge portion 11, the PET film 2 is at least partially covered The second surface 14 between the curved outer surface and the inner surface of the first edge portion 11 is connected.

[0081] Specifically, the first edge portion 11 of the substrate 1 is configured as a curved surface, and the PET film 2 is attached to the first surface 13 of the substrate 1 by using an optically transparent adhesive 3 for attachment. The first surface 13 is the curved inner surface of the first edge portion 11 , that is, the inner surface of the substrate 1 . The PET film 2 at least partially covers the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com