A kind of charging device and charging method of AGV trolley

A charging device and power device technology, applied in circuit devices, battery circuit devices, charging of different batteries, etc., can solve the problems of reducing the flexible change of the route and increasing the construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

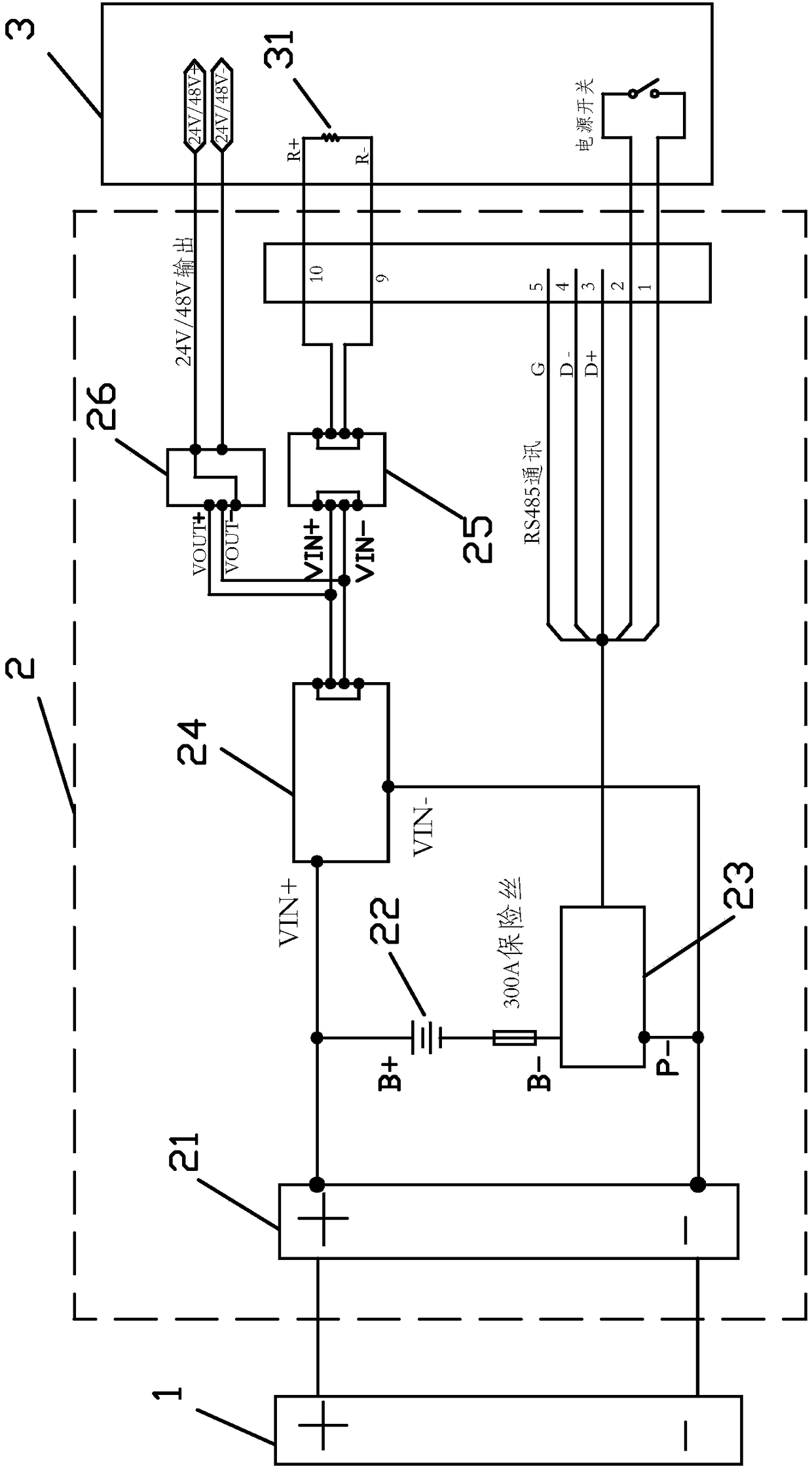

[0024] Such as figure 1 As shown, the charging device mainly includes a receiving device 1, a power supply device 2, an AGV system 3, and a wireless transmitting device not shown in the figure.

[0025] Wherein, the power supply device 2 mainly includes a charging terminal 21 , a lithium ion capacitor module 22 (ie, a LIC module), a battery management system (BMS) 23 , a regulated power supply 24 and a braking plate 25 . The lithium-ion capacitor module 22 is composed of several lithium-ion capacitor cells connected in series end to end. The positive pole of the lithium-ion capacitor module 22 is connected to the positive pole of the charging terminal 21, and the negative pole of the lithium-ion capacitor module 22 passes through the 300A fuse and the battery management system in turn. 23 is connected to the negative pole of the charging terminal 21 to form a charging closed circuit. The battery management system 23 is used to monitor signals such as voltage, current, tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com