Cleaning device for guide rod of LCD glass substrate deposition operation frame

A technology for cleaning devices and glass substrates, which is applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems of chemical safety hazards, difficult handling of personnel, and low cleaning efficiency, so as to save labor consumption, broaden the value of promotion, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

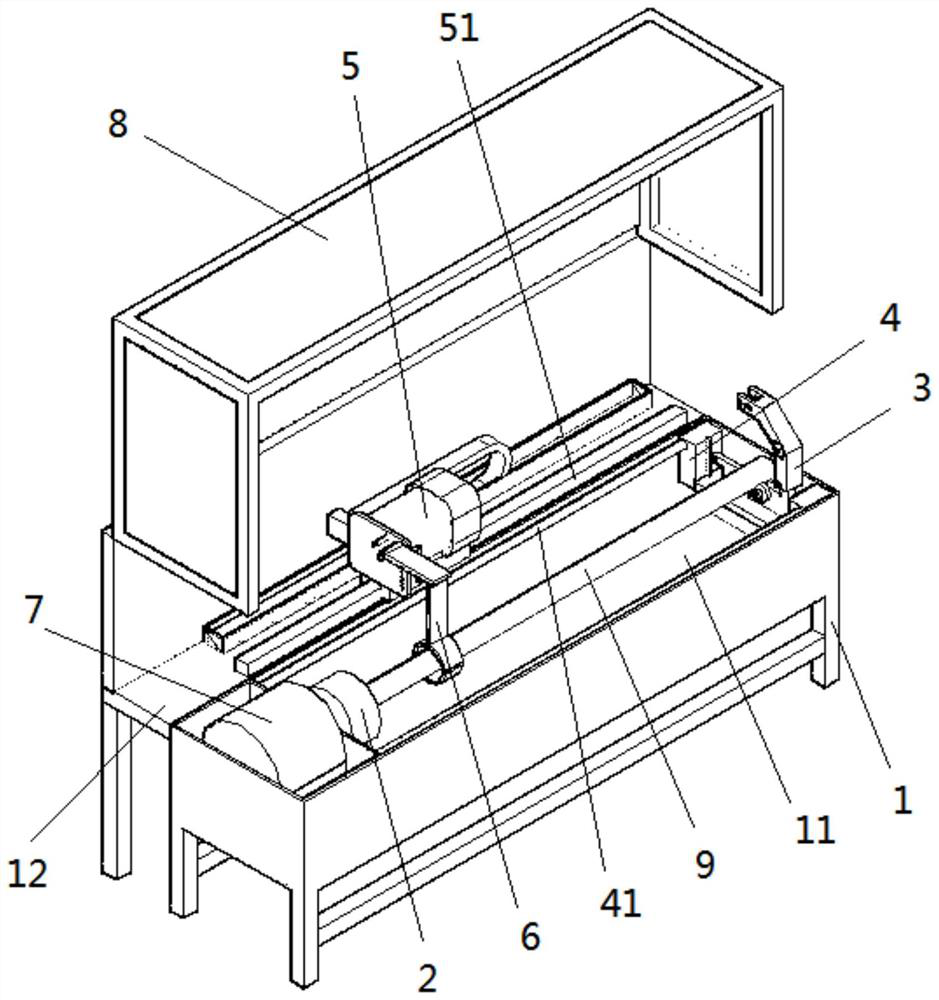

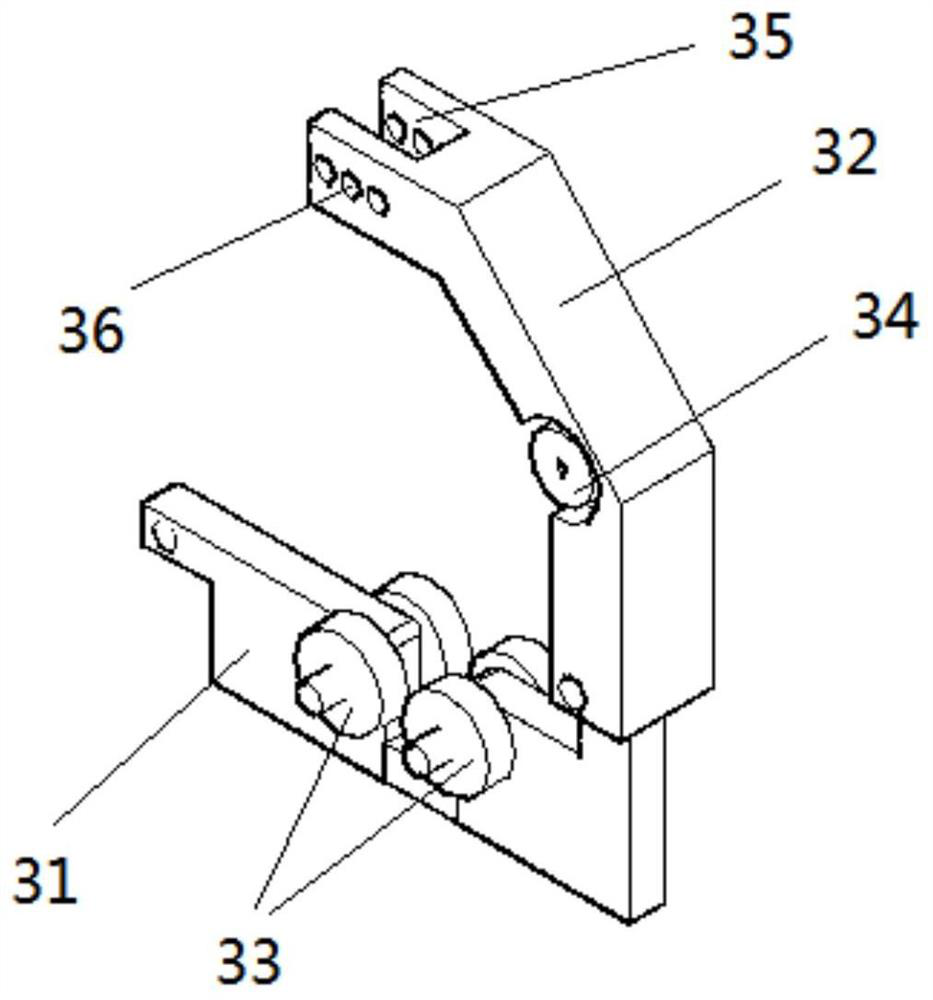

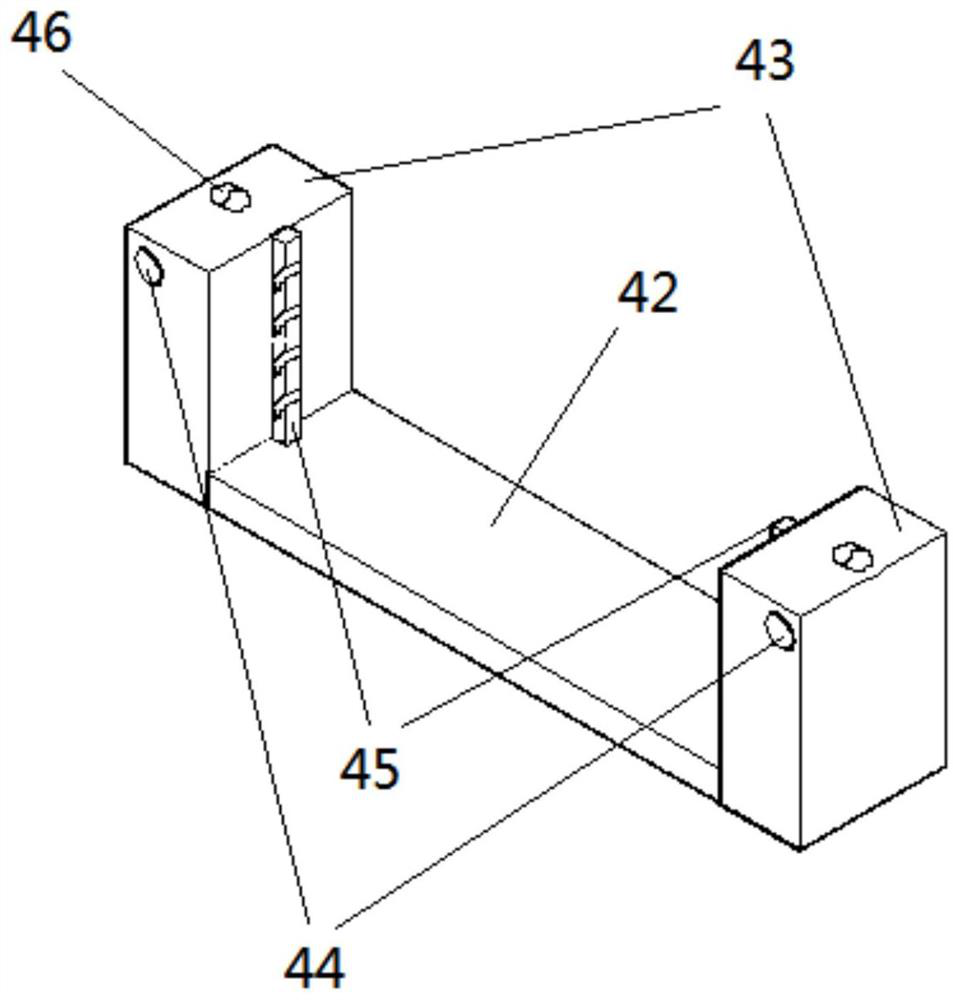

[0029] A cleaning device for frame guide rods used in LCD glass substrate deposition operations, including a cleaning pool 11 arranged on a frame 1, a workbench 12 is provided on the side of the cleaning pool 11, and the bottom of the cleaning pool 11 is lower than the workbench 12 The side wall at one end of the cleaning tank 11 in the length direction is provided with a chuck 2, the side wall of the cleaning tank 11 opposite to the chuck 2 is provided with a support mechanism 3, the workbench 12 is provided with a guide mechanism 5, and on the guide mechanism 5 A cleaning mechanism 6 that can interact with the workpiece 9 is provided, and the guiding mechanism 5 can drive the cleaning mechanism 6 to recipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com