Rapid temperature control system for wire-mesh reactors

A technology of temperature control system and reactor, which is applied in the direction of temperature control, general control system, control/regulation system, etc. It can solve the problems that heating can only be completed once, it is not suitable for high-speed heating process control, and it cannot be adjusted arbitrarily, so as to achieve simple implementation , Heating speed is flexible and adjustable, and it is easy to copy the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

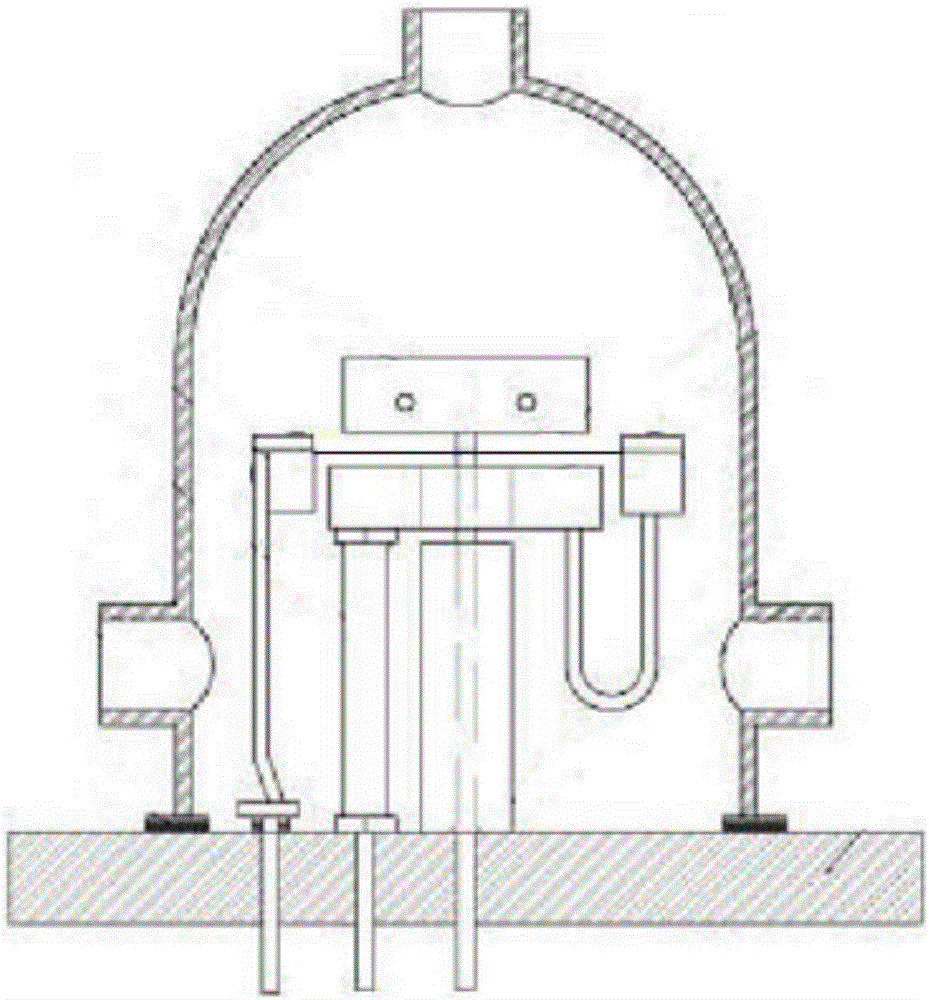

[0029] The method of the present invention is applied to the experimental platform system of the line network reactor, and the system can simulate the heating process of the boiler and analyze the characteristics of the pulverized coal. figure 1 It is the structural diagram of the experimental platform system of the wire grid reactor. figure 2 It is the topological diagram of the control system of the wire mesh reactor of the present invention; a kind of fast temperature control system facing the wire mesh reactor is characterized in that, comprising:

[0030] The core control unit is used to realize the analog-to-digital conversion of the temperature signal, the digital-to-analog conversion of the control signal, and the core control algorithm;

[0031] The sensing and transmitting unit includes thermocouples and temperature transmitters, which are used to collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com