A kind of working method of optical cable stripping equipment

A working method and technology of optical cables, applied in the equipment, light guide, optics, etc. of dismantling/armored cables, can solve the problems of low degree of intelligence, inability to cut, and inability to realize automatic cutting, and achieve remote control and reduce difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

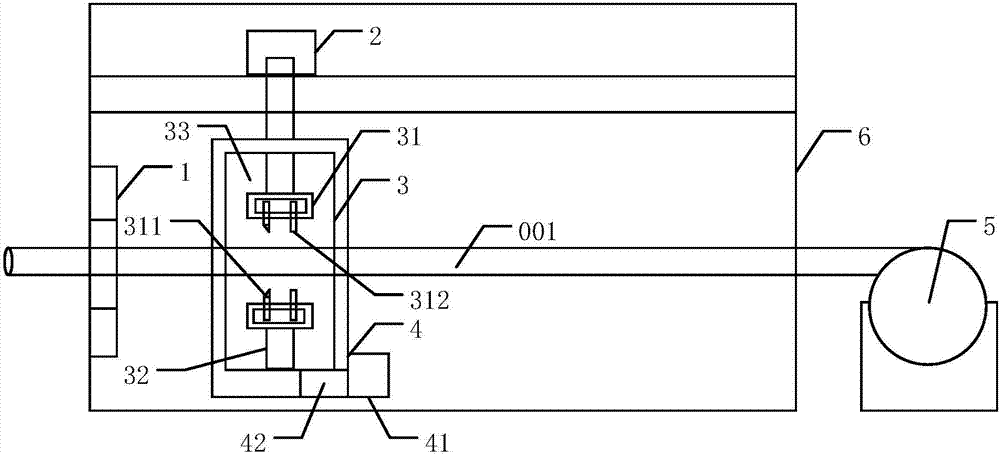

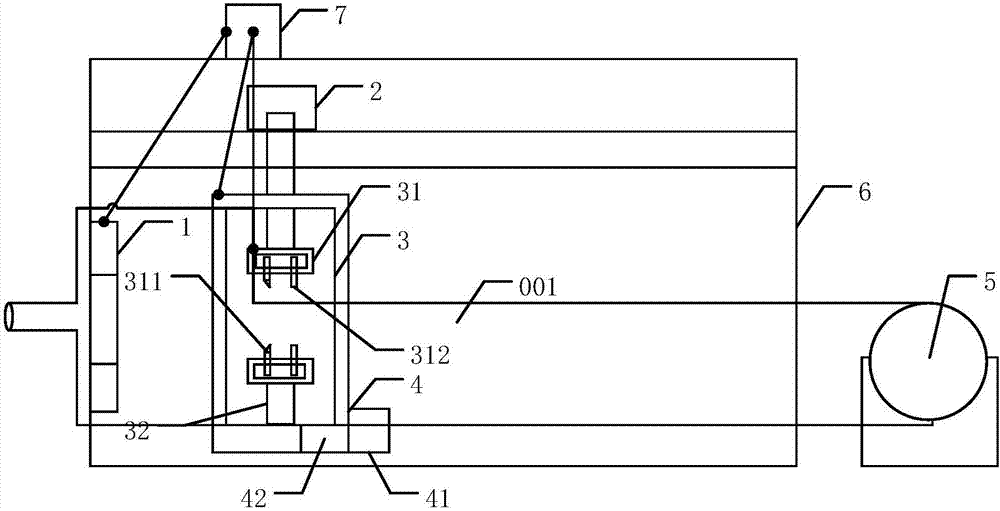

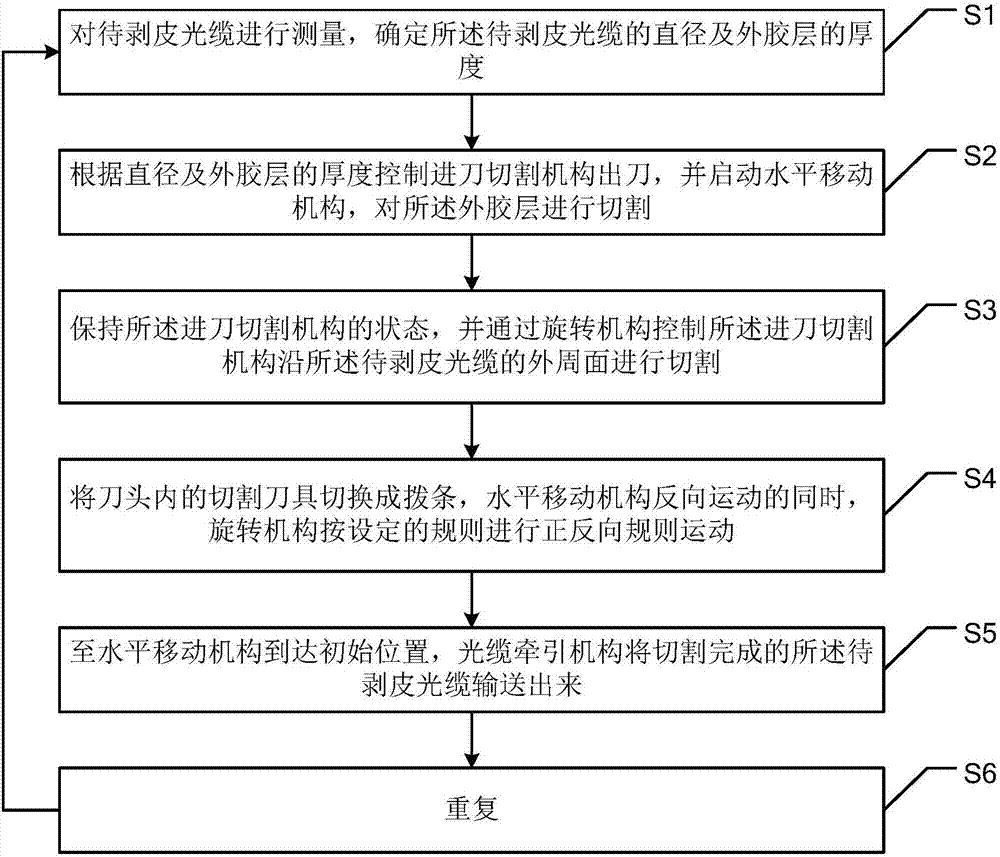

[0056] The invention discloses an optical cable stripping device and a working method thereof. The optical cable to be stripped is firstly measured by a measuring mechanism, and then the knife is fed and cut by a cutting mechanism according to the measurement result, and the cutting is controlled by a horizontal moving mechanism and a rotating mechanism. The cutting tool is switched to the method of loosening the outer rubber layer of the optical cable to be stripped by the pick bar, which can effectively cut the peeled optical cable while loosening the outer rubber layer of the optical cable to be stripped, which can greatly reduce the difficulty of optical cable stripping.

[0057] The technical solutions in the embodiments of the present invention will be described clearly and in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com