A Thick-Walled Structure Defect Detection Method Based on Oblique Incident Ultrasonic Synthetic Aperture Focusing

A technology of ultrasonic synthesis and ultrasonic detection, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measurement devices. It can solve the problems of large energy attenuation, difficulty, and high resolution in ultrasonic detection Large energy coverage, improved defect detection efficiency, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

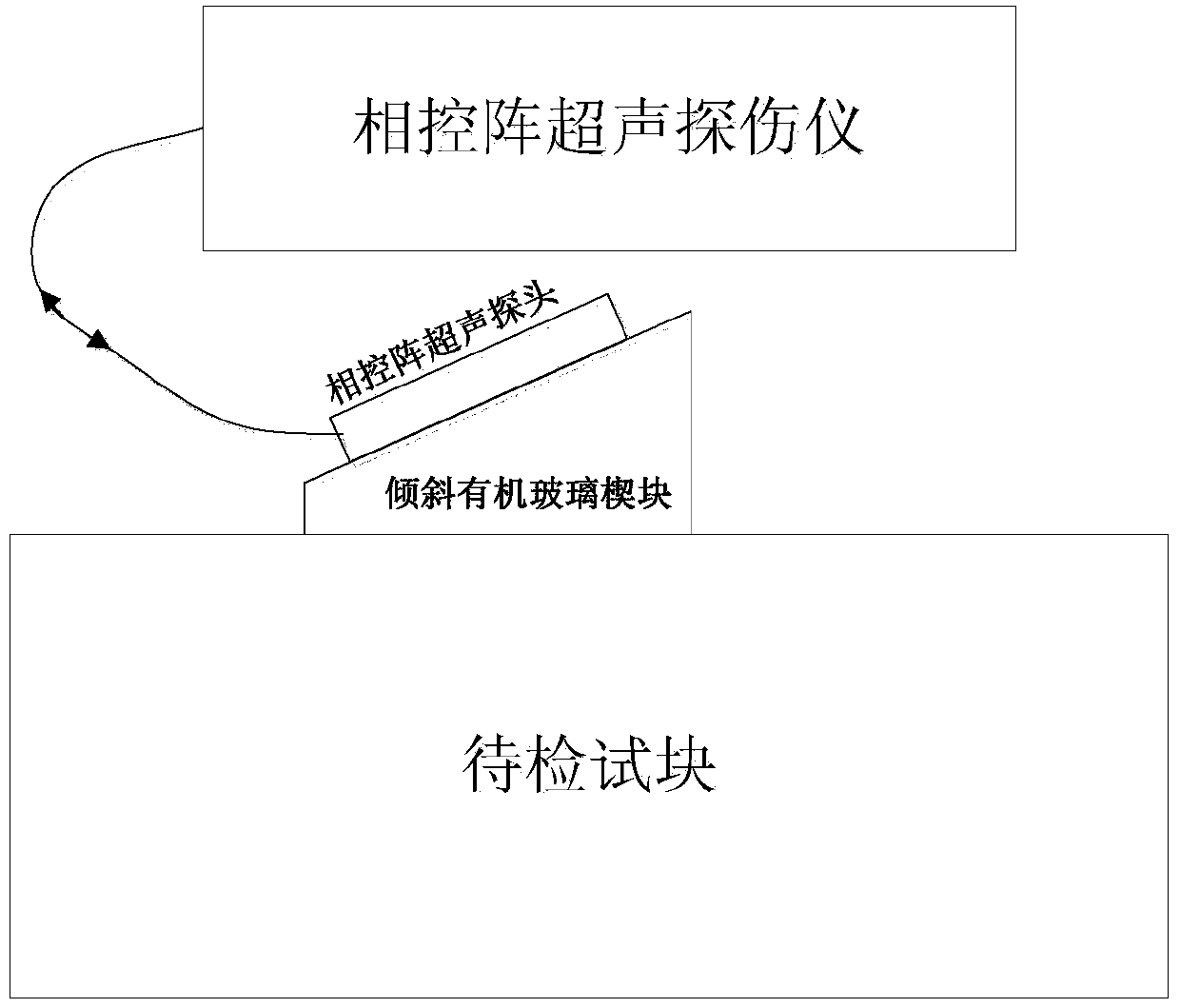

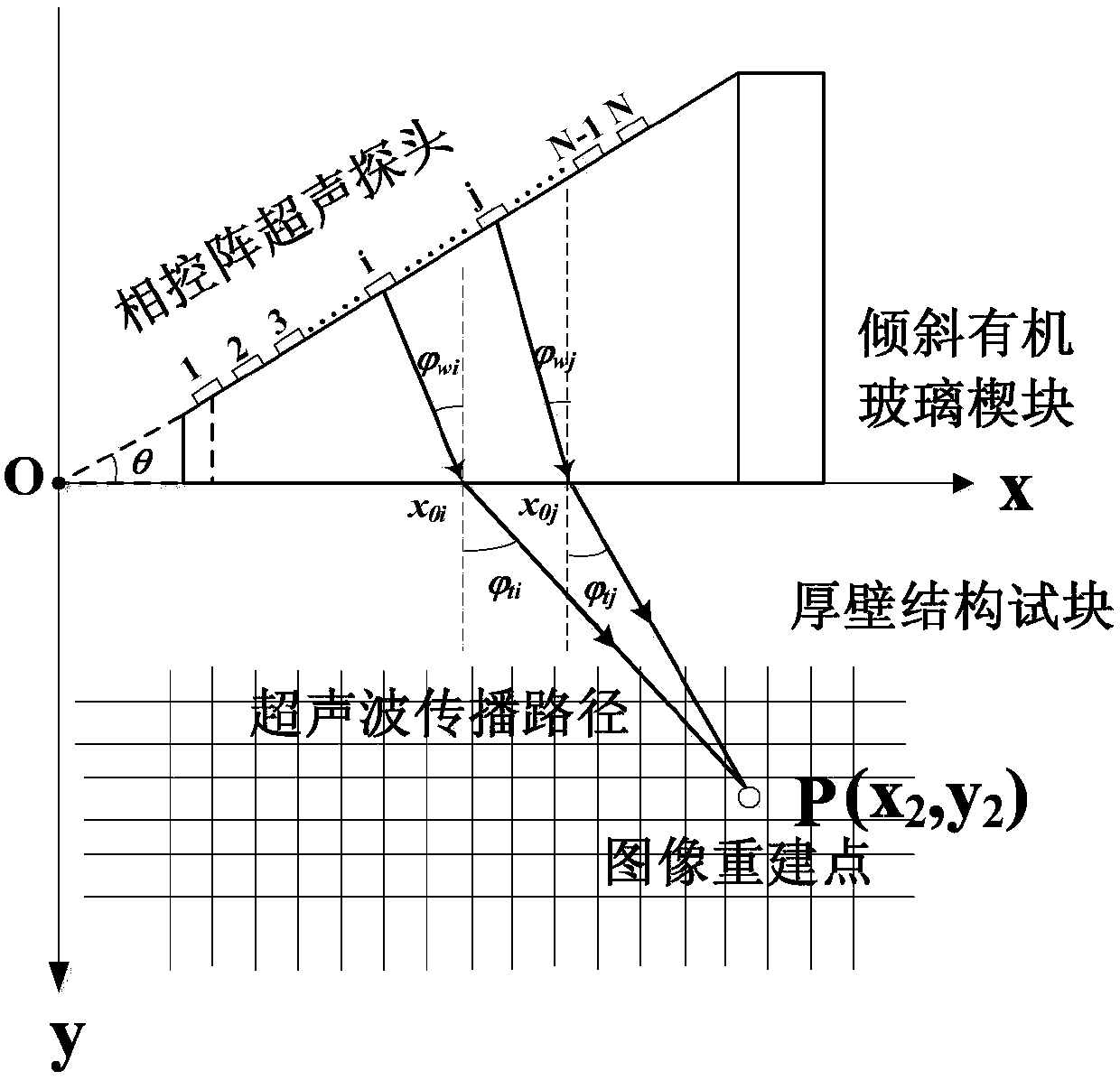

[0041] Thick-walled structure defect detection method based on oblique incident ultrasonic synthetic aperture focusing, the ultrasonic detection system used is as follows: figure 1 As shown, including phased array ultrasonic detector, phased array ultrasonic probe, inclined plexiglass wedge, etc. The specific detection and processing steps are as follows:

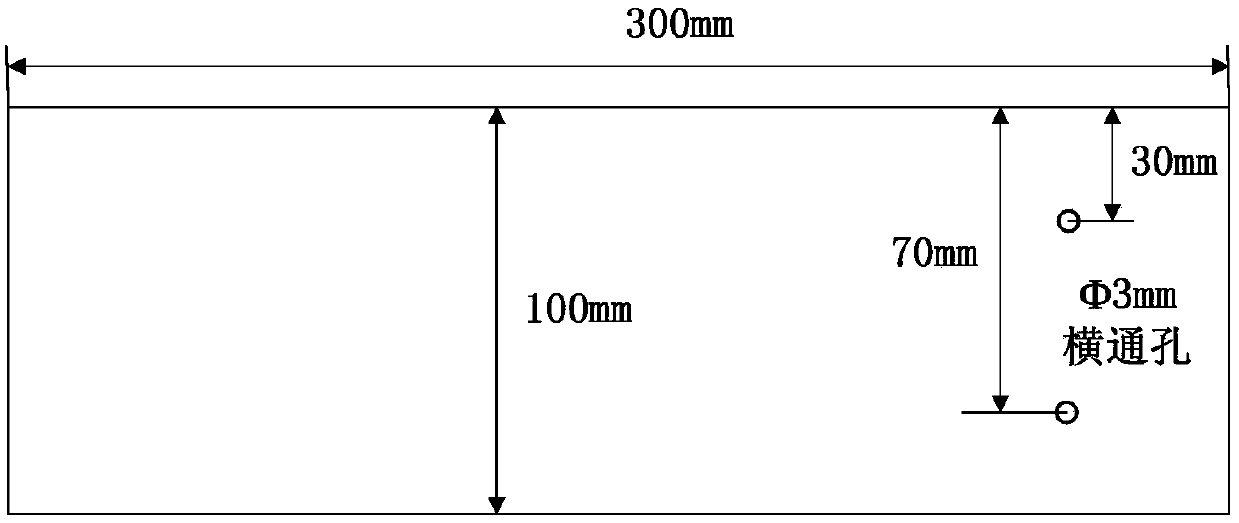

[0042] (a) Select a carbon steel test block with a wall thickness of 100mm. The size of the test block is 100mm×300mm×40mm. figure 2 shown.

[0043] (b) Using the M2M Multi X++ digital flaw detector, the phased array ultrasonic probe is used to electronically scan the defects of the transverse through holes in the test block, and the position and depth of the defects are preliminarily determined. Among them, the center frequency of the phased array ultrasonic probe is 5MHz, the aperture of the phased array ultrasonic probe is 38.4mm×10mm, the pitch of the phased array array is 0.6mm, the sub-aperture is 2.4mm×10mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com