Protection structure for zirconium element outer electrode lead of oxygen sensor and preparation method of protection structure

A lead wire protection, oxygen sensor technology, used in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems of breaking the external electrode, influence, product failure, etc., and achieve the effect of improving durability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

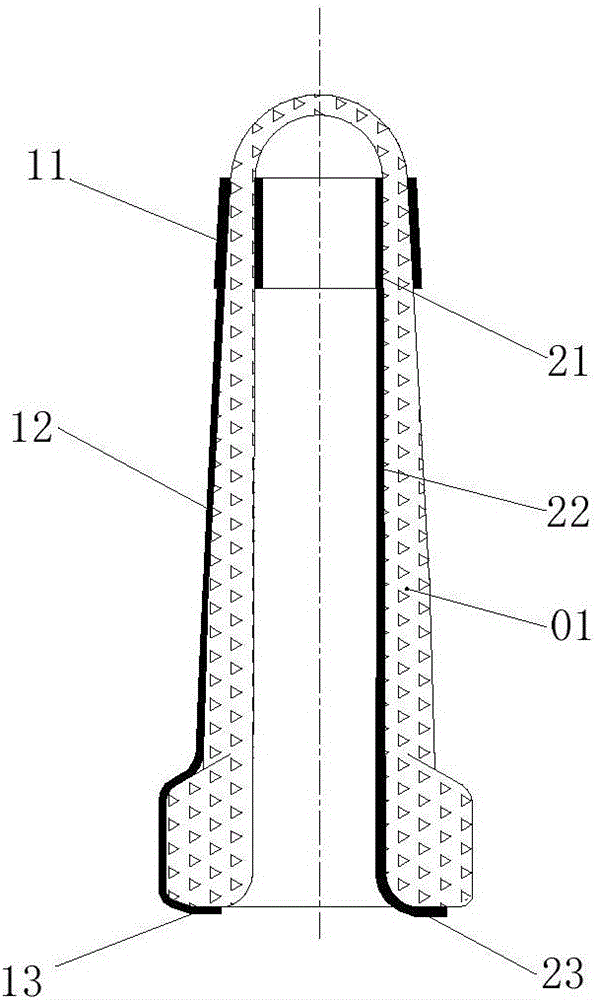

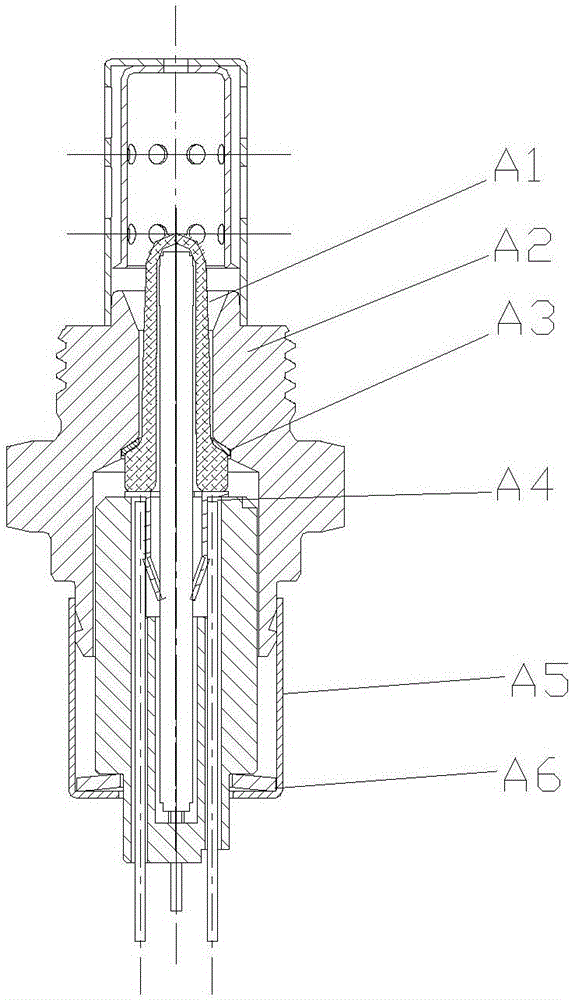

[0031] After the zirconia ceramic powder is isostatically pressed, a larger ceramic body is obtained, which is processed to the required product size by turning or grinding, and then the inner and outer sides of the tubular zirconium element are coated with platinum slurry respectively. After drying, the inner and outer electrode contact discs are respectively coated, and further dried, and then the inner and outer electrode leads are coated, and further dried to obtain an unsintered tubular zirconium element.

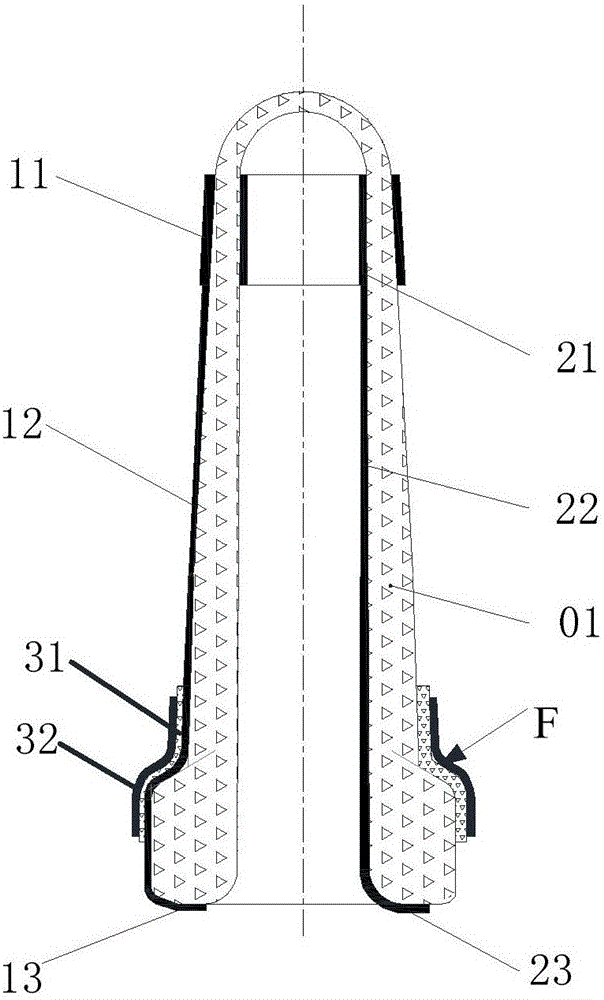

[0032] After the lead wire of the external electrode of the zirconium element is prepared, a layer of ceramic material slurry (zirconia slurry) is applied on the sealing surface area F, and then dried. The preparation process of the slurry is: add 70wt% zirconia ceramics, 20wt% terpineol, 2wt% modified fish oil, 5wt% ethyl cellulose, 3wt% ortho Diethyl phthalate, prepared after ball milling for 18 hours.

[0033] After drying, the zirconia slurry and the matrix of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com