High precision vibrating wire type micro-pressure sensor

A vibrating wire micro-pressure sensor technology, applied in the direction of fluid pressure measurement of elastic deformation gauge, can solve the problems of easy damage, inability to realize limit micro-pressure, low measurement stability, etc., to achieve increased contact surface, high measurement The effects of accuracy and over-range measurement capability, and high environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

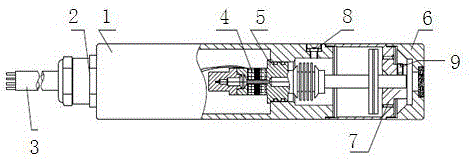

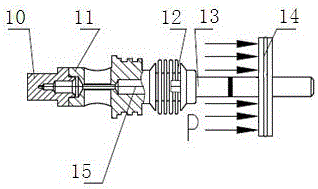

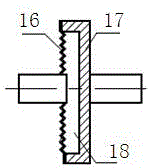

[0030] A high-precision vibrating wire type micro-pressure sensor, including a housing 1, a cable joint 2 connecting a cable 3, an induction coil 4, a micro-pressure sensitive part 5, an internal blocking cover with a central hole 7, and a water-permeable part 6; the micro-pressure sensitive Component 5 and shell 1 are welded into an integrated structure. One end of shell 1 is connected to cable joint 2, and the other end is connected to water-permeable component 6. Induction coil 4, micro-pressure sensitive component 5, and internal blocking cover 7 are arranged inside shell 1. Cable joint 2, induction coil 4, micro-pressure sensitive part 5 and internal blocking cover 7 are sequentially connected; micro-pressure sensitive part 5 includes upper end 10, main body 11, flexible stainless steel bellows 12, lower end 13, vacuum membrane box 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com