Heat treatment production method of steel rail for mixed passenger and freight traffic railway and obtained steel rail

A technology of mixed transportation of passengers and cargo, rails, applied in heat treatment furnaces, heat treatment equipment, rails, etc., can solve problems such as difficult to effectively meet the user's rail production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

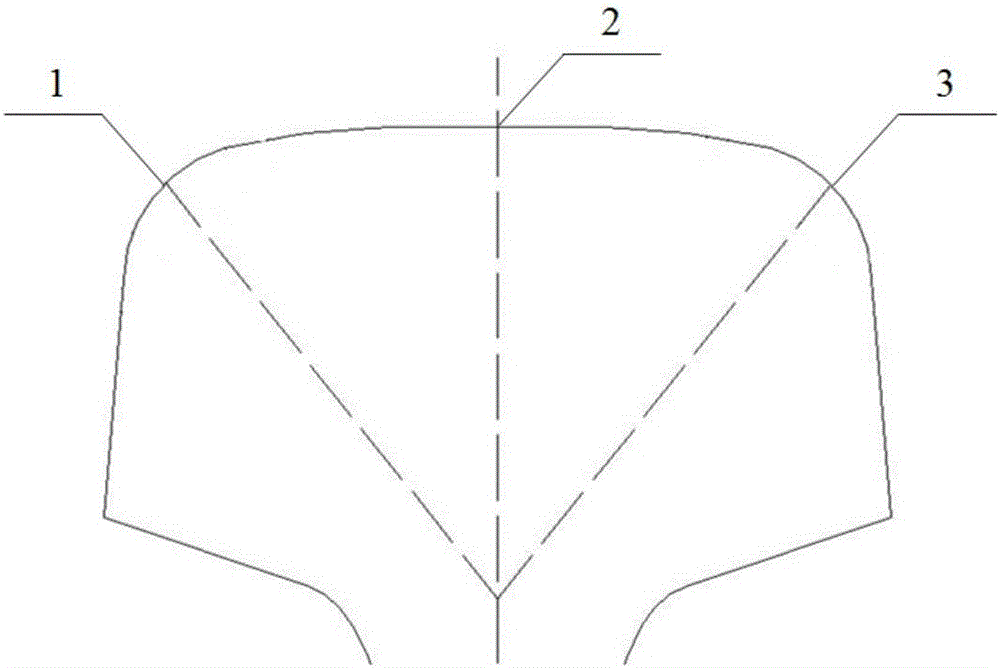

Image

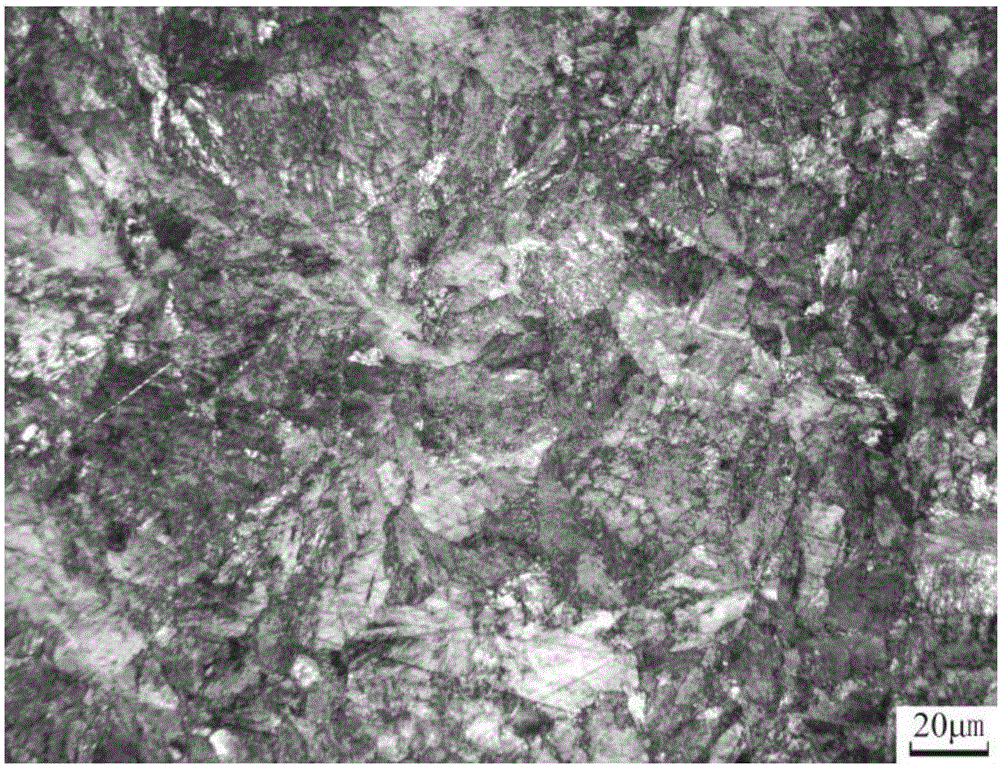

Examples

Embodiment 1

[0032] (1) Molten steel smelting: Smelting is carried out with low-S furnace molten iron with an S content of about 0.008% by weight. During the smelting process, refining slag composed of aluminum oxide, barium oxide and calcium fluoride (wherein the percentage content is w(Al 2 o 3 )=23% by weight, w(BaO)=10% by weight, w(CaF 2)=5% by weight) and a recarburizing agent composed of anthracite and low N alloy, use a foaming agent in the heating process of the LF furnace, and control the composition content to finally obtain the molten steel of the chemical composition shown in 1# in Table 1.

[0033] (2) The molten steel obtained in step (1) is fully protected and cast into a steel billet, and then sent to the slow cooling pit for slow cooling at a rate of 0.3°C / min, and the steel billet cooled to room temperature is sent into a heating furnace for heating and heat preservation ( The heating rate is 10°C / min, the termination temperature (tapping temperature) is 950°C, and the...

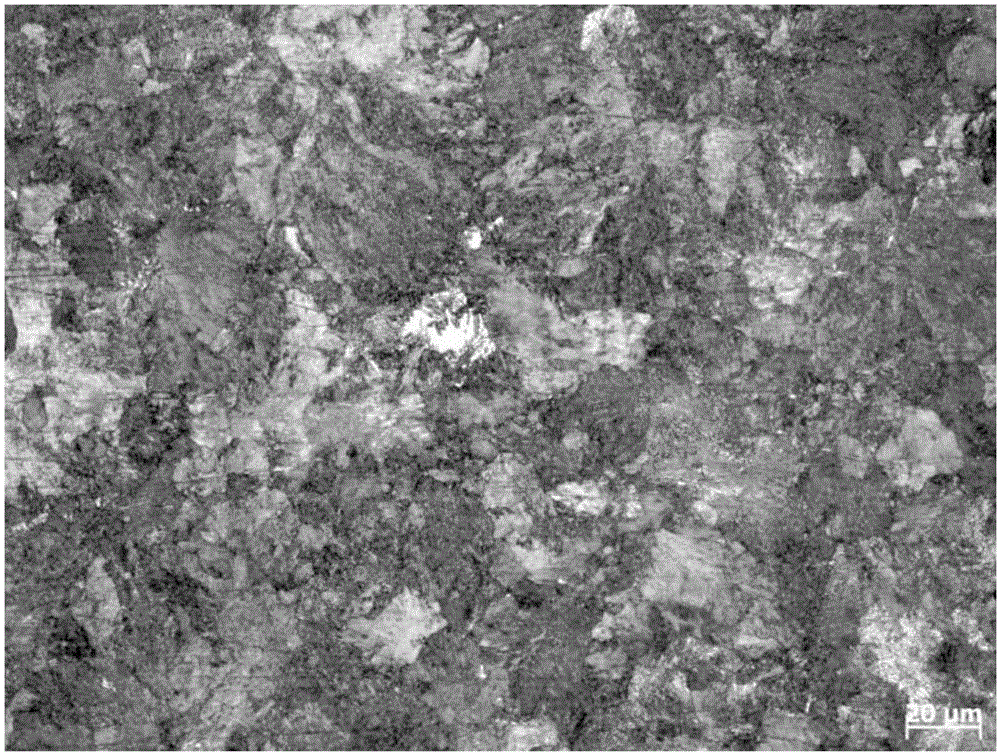

Embodiment 2-6

[0036] According to the method of Example 1, the difference is that the chemical composition of the molten steel obtained by smelting is as shown in Table 1 and Table 2, and the specific operating parameters of the method are as shown in Table 1.

[0037] Table 1

[0038]

[0039] Table 2

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com