Intelligent temperature controlling and filtering type aluminum alloy aging furnace and working method thereof

A filter type, aluminum alloy technology, applied in the field of aluminum alloy manufacturing, can solve the problems of large dust impurity content, affecting the effect of workpiece aging treatment, and achieve the effect of stable and uniform heating and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

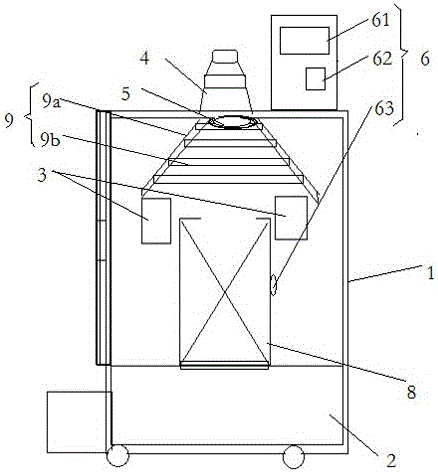

[0019] Such as figure 1 The shown intelligent temperature control filtering type aluminum alloy aging furnace includes a furnace body 1, a loading and unloading trolley 2, a heating device 3, a ventilation device 4, an air filter 5 and a temperature control device 6, and the temperature control device 6 includes a PLC Controller 61, touch display screen 62 and temperature testing device 63, described furnace body 1 top is provided with ventilating device 7, is provided with air filter 5 below ventilating device 7, furnace body 1 interior comprises furnace hearth 8, and air guiding device 9 is provided with On the top of the furnace 8, the bottom of the furnace 8 is provided with a loading and unloading trolley 2, the two sides of the furnace 8 are provided with a heating device 3, and the outer wall of the furnace 8 is provided with a temperature testing device 63, and the output end of the temperature testing device 63 is arranged on the furnace body 1. The input end of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com