Punching blanking device for automobile sheet metal part

A technology for automotive sheet metal parts, punching and blanking, applied in vehicle parts, transportation and packaging, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

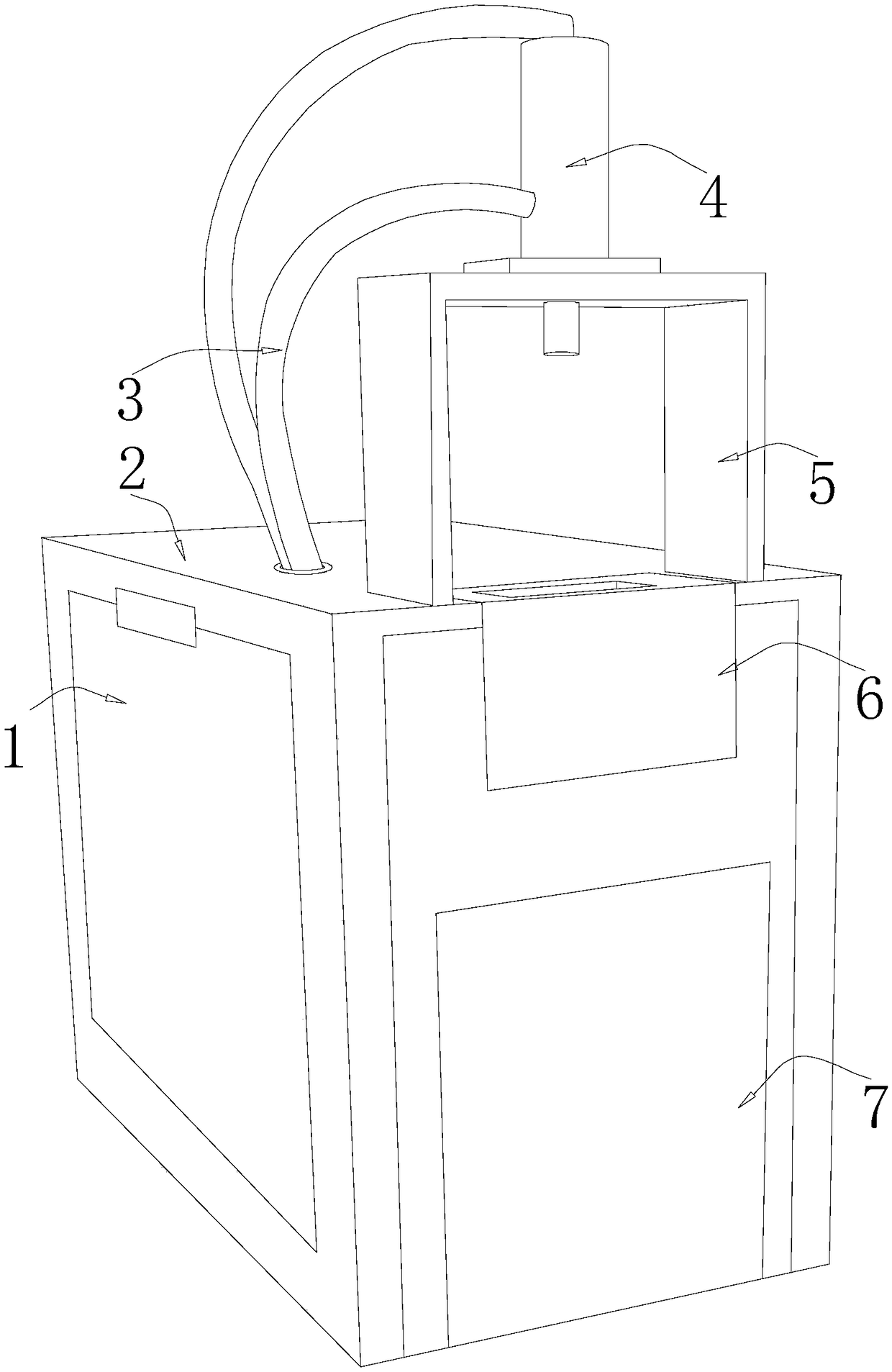

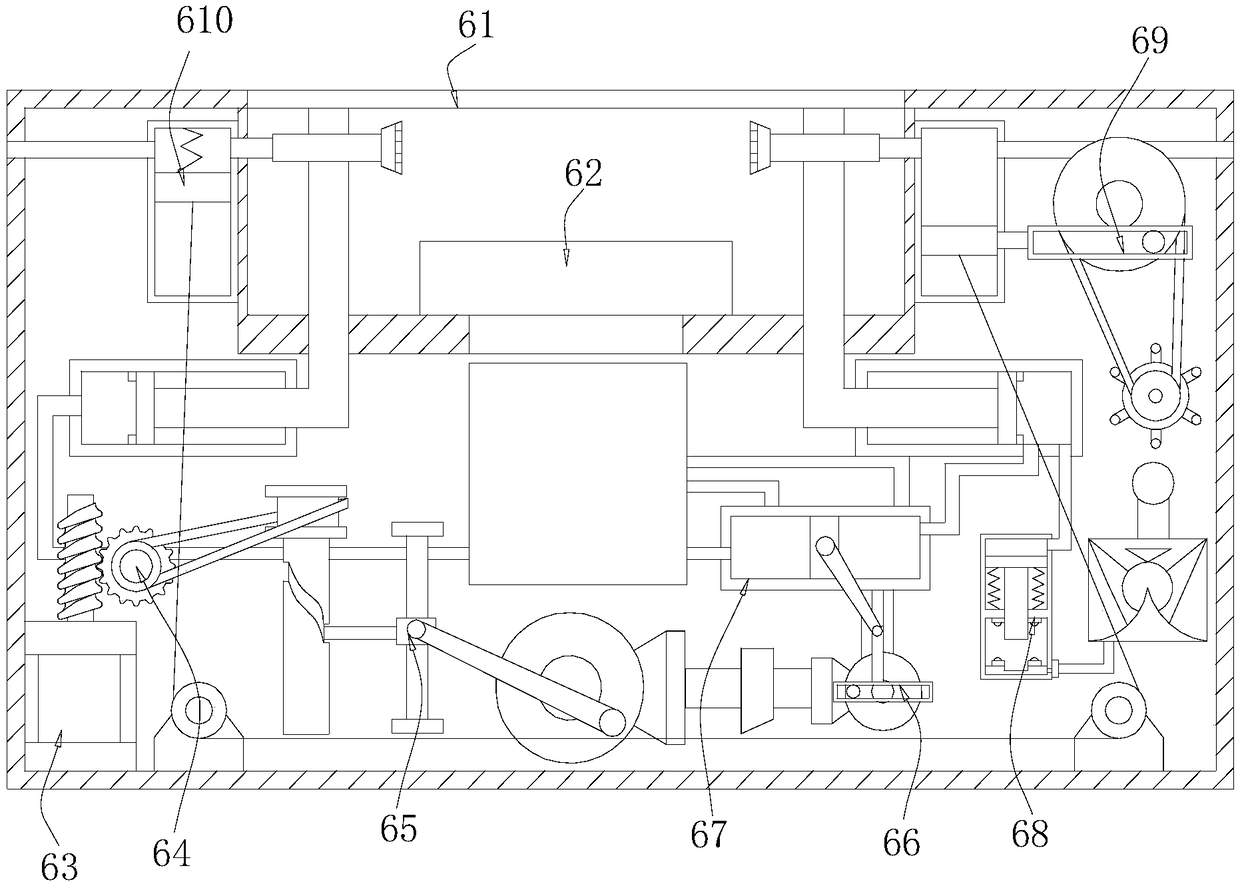

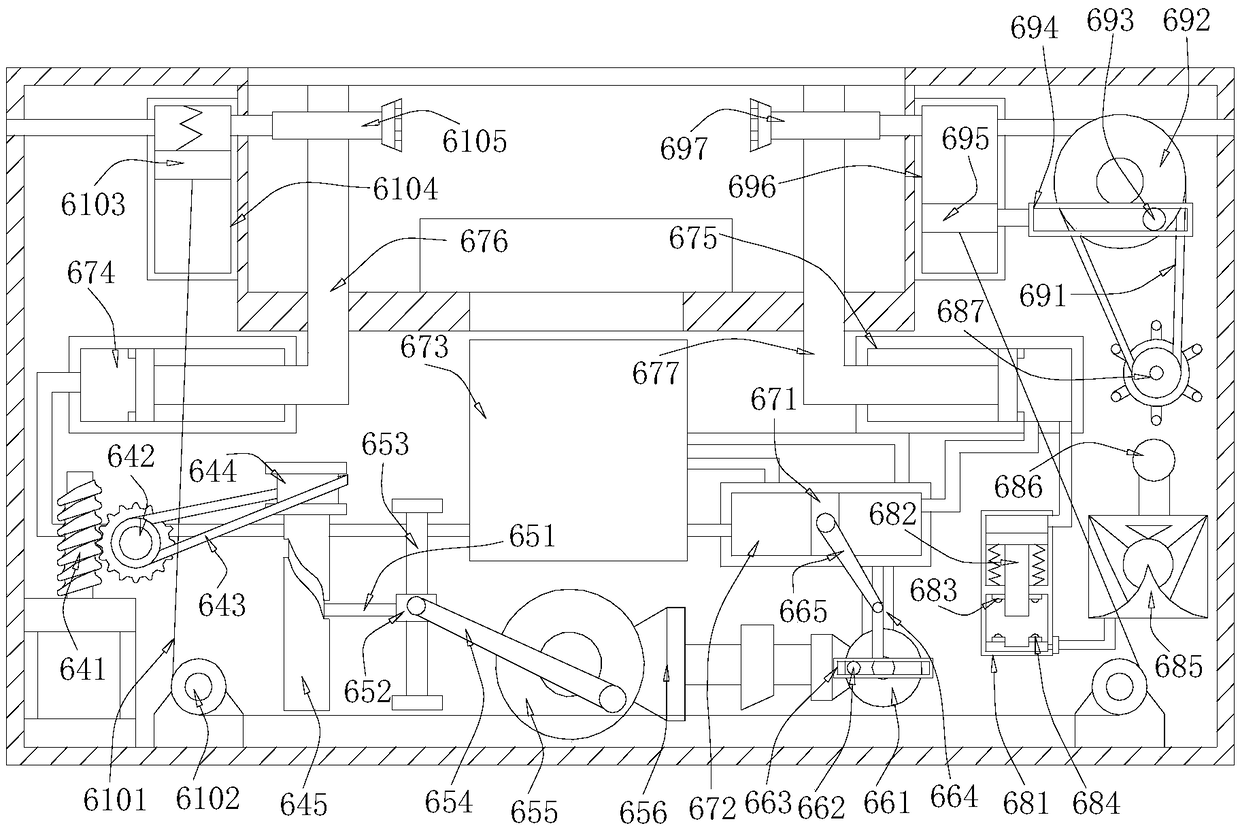

[0025] like Figure 1-4 As shown in the figure, the present invention provides a technical solution of a punching and blanking device for automobile sheet metal parts:

[0026] A punching and blanking device for automobile sheet metal parts, the structure of which includes a maintenance cabinet door 1, a workbench body 2, connecting wires 3, a pneumatic punching device 4, a supporting mounting frame 5, an overflow fixed lubrication cooling device 6, a blanking Cavity 7, the maintenance cabinet door 1 is hinged to the left end surface of the workbench main body 2, one end of the connecting wire 3 is embedded and installed on the upper surface of the workbench main body 2, the other end of the connecting wire 3 is connected to the pneumatic punching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com