Electric heating cycle hot blast stove

A hot blast stove and electric heating technology, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high equipment operation noise, complex design, and heavy workload, and achieve low equipment operation noise and increase Heat dissipation area and the effect of improving thermal efficiency

Inactive Publication Date: 2014-05-14

JIANGSU ZHONGLI PETROCHEM EQUIP

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The hot blast stove used in the existing coating production line generally has the following disadvantages: complex design, heavy workload, complicated installation, commissioning, and maintenance, high noise in equipment operation, poor sealing of the hot blast stove main body, and the air in the heating furnace Not clean enough, affecting the coating process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

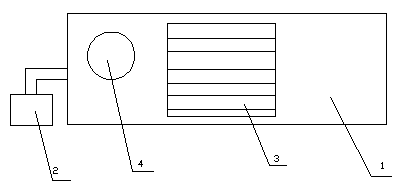

[0008] The electric heating circulating hot blast stove includes a fully sealed hot blast stove body 1, the outside of the furnace body 1 is integrally connected with a plug-in fan 2, and the furnace body 1 is provided with a filter 4 and a heating component 3, the heating component 3 includes a steel pipe and Heat radiating fins, the heating assembly 3 is a drawer structure.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an electric heating cycle hot blast stove. The hot blast stove comprises a hermetic stove body of the hot blast stove, wherein an insert fan is wholly connected with the outside of the stove body, a filter and a heating component are arranged in the stove body, the heating component comprises steel pipes and radiating fins, and the heating component is in a drawer type structure. The hot blast stove which is in a monolithic structure is convenient to mount, debug and maintain, low in equipment operation noise, and good in effects. The high-temperature high-efficiency filter is used so that heated circulating air is cleaner to completely satisfy the requirement of drying varnish of a limousine; the heating component selects the stainless steel pipes and the radiating fins for use, radiating areas are increased, heat efficiency is increased, and the heating component is high efficient and energy-saving.

Description

Technical field [0001] The invention relates to a heat source device of a hot air circulating drying chamber in a coating production line, in particular to an electric heating circulating hot air stove. Background technique [0002] The hot blast stove used in the existing coating production line generally has the following shortcomings: complex design, large workload, complicated installation, debugging, and maintenance, equipment operation noise is very large, the main body of the hot blast stove is not well sealed, and the air in the heating furnace Not clean enough, affecting the coating process. Summary of the invention [0003] In order to solve the above problems, the present invention provides an electric heating circulating hot blast stove with simple structure, easy installation, stable operation and improved thermal efficiency. [0004] The technical solution of the present invention is to include a fully sealed hot blast furnace body, the body of the furnace body is int...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24H3/02F24H9/18

Inventor 高宏军

Owner JIANGSU ZHONGLI PETROCHEM EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com