Blast furnace gas pipeline alkali spraying and deacidification device and process

A blast furnace gas and pipeline technology, applied in the field of metallurgy, can solve the problems of corrosion of clean gas pipelines and gas equipment, shortening the service life of pipelines and equipment, large resistance loss of pipeline network, etc. The effect of small resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

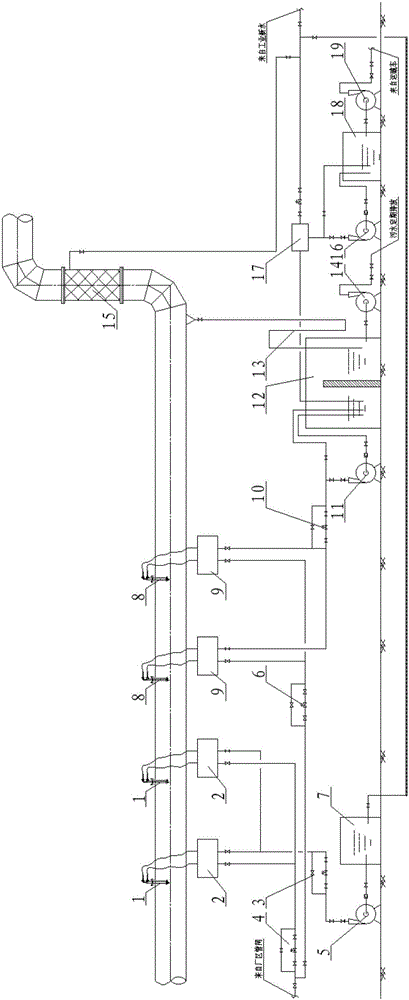

[0023] In order to better understand the purpose, structure and function of the present invention, a blast furnace gas pipeline alkali spraying deacidification device and process of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the blast furnace gas pipeline alkali spraying deacidification device of the present invention includes a cooling spray gun 1, an alkali liquor spray gun 8 and a gas eliminator 15 arranged in sequence on the blast furnace gas pipeline. Among them, the cooling spray gun 1 is used to inject the mixed cooling nitrogen and industrial new water into the blast furnace gas pipeline through atomization, so as to reduce the temperature of the blast furnace gas and make the water vapor in the blast furnace gas saturated; the lye spray gun 8 is used for The mixed caustic spraying nitrogen and circulating lye are atomized and sprayed into the blast furnace gas pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com