Saturated hydrogenation method of petroleum hydrocarbon cracking C3-C8 fractions

A technology of petroleum hydrocarbons and distillates, applied in chemical instruments and methods, petroleum industry, through selective hydrofining, etc., can solve the problems of low catalytic activity and loss of activity of non-precious metals, achieve excellent cost and effect, and prevent coking , the effect of low temperature reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

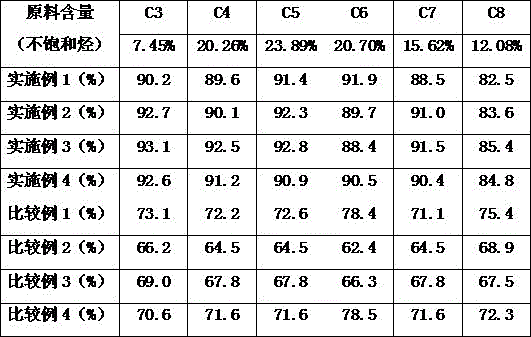

Examples

Embodiment 1

[0020] A saturated hydrogenation method for cracking C3-C8 fractions of petroleum hydrocarbons, characterized in that the method comprises contacting and reacting the fractions with hydrogen under hydrogenation conditions and in the presence of a hydrogenation catalyst, wherein the catalyst used is Pt-Co-Cu The base hydrogenation catalyst is characterized in that the hydrogenation process conditions are: fixed bed reactor inlet temperature 30°C, reaction temperature 350°C, reaction pressure 3.0MPa, liquid volume space velocity 3.0h -1 , the volume ratio of hydrogen to oil is 200; the Pt-Co-Cu-based hydrogenation catalyst is prepared by loading the main active component and the auxiliary active component on the carrier, including the main active components Pt, Co and Cu, and the auxiliary active components are W, Zr, La and P, the carrier is X, based on the mass percentage of the catalyst composition: containing platinum 0.05%, cobalt 3%, copper 5%, tungsten 0.5%, zirconium 0.5%...

Embodiment 2

[0022] A saturated hydrogenation method for cracking C3-C8 fractions of petroleum hydrocarbons, the method comprises contacting and reacting the fractions with hydrogen under hydrogenation conditions and in the presence of a hydrogenation catalyst, wherein the catalyst used is a Pt-Co-Cu-based hydrogenation catalyst , characterized in that the hydrogenation process conditions are: fixed bed reactor inlet temperature 40°C, reaction temperature 400°C, reaction pressure 3.0MPa, liquid volume space velocity 4.0h -1 , the volume ratio of hydrogen to oil is 260; the Pt-Co-Cu-based hydrogenation catalyst is divided into W, Zr, La and P on the carrier, and the carrier is X, based on the mass percentage of the catalyst composition: containing 0.1% platinum, cobalt 6%, 10% copper, 1.5% tungsten, 1% zirconium, 2% lanthanum, 1% phosphorus, and the balance is carrier X, wherein carrier X is a composite carrier, Al doped by Na 2 o 3 Composite composition with MCM-41 molecular sieve at a we...

Embodiment 3

[0024]A saturated hydrogenation method for cracking C3-C8 fractions of petroleum hydrocarbons, characterized in that the method comprises contacting and reacting the fractions with hydrogen under hydrogenation conditions and in the presence of a hydrogenation catalyst, wherein the catalyst used is Pt-Co-Cu The base hydrogenation catalyst is characterized in that the hydrogenation process conditions are: fixed bed reactor inlet temperature 50°C, reaction temperature 450°C, reaction pressure 4.0MPa, liquid volume space velocity 5.0h -1 , the hydrogen-to-oil volume ratio is 400; the Pt-Co-Cu-based hydrogenation catalyst is prepared by loading the main active components and auxiliary active components on the carrier, including the main active components Pt, Co and Cu, and the auxiliary active components are W, Zr, La and P, the carrier is X, based on the mass percentage of the catalyst composition: containing platinum 0.07%, cobalt 4%, copper 7%, tungsten 0.8%, zirconium 0.6%, lant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com