Anti-corrosion paint for chimney climbing ladder and preparation method thereof

A technology for anti-corrosion paint and ladders, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve problems such as corrosion of the outer wall of chimneys and ladders, and achieve good anti-corrosion effect, good chemical resistance, and strong adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

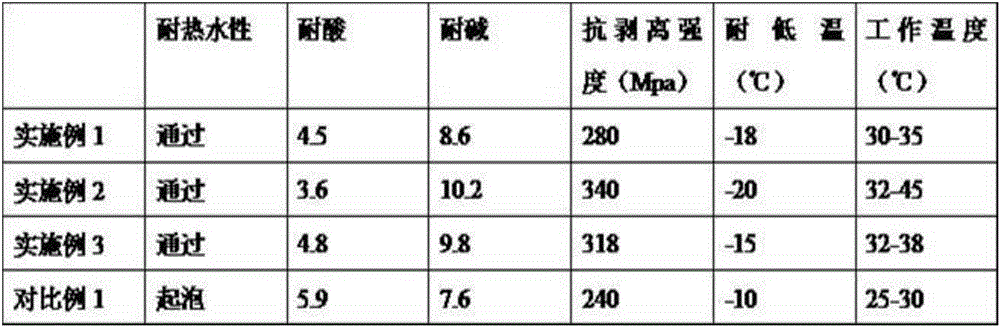

Examples

Embodiment 1

[0020] A kind of anticorrosion paint for chimney ladder, comprising following raw materials in parts by weight: 22 parts of water-based epoxy curing agent, 2 parts of trimerized DMP-30 accelerator, 20 parts of high temperature resistant vinyl ester resin paint base, toughening agent 1 part, 2 parts of anti-settling agent, 1 part of mica powder, 2 parts of talc powder, 3 parts of 400 mesh tungsten metal powder, 22 parts of glycerin, 1 part of antimony trioxide, 12-20 parts of magnesium chloride.

[0021] The preferred anti-corrosion paint is the tungsten metal powder.

[0022] The preparation method of above-mentioned chimney climbing ladder with anticorrosion paint, comprises the following steps:

[0023] Step 1. Weigh the raw materials, mix the high-temperature resistant vinyl ester resin paint base, toughening agent, anti-settling agent, glycerin, antimony trioxide and magnesium chloride, put them into the reaction kettle, and heat at 2°C / min to 50 °C to obtain the first mi...

Embodiment 2

[0029] A kind of anticorrosion paint for chimney ladder, comprising following raw materials by weight: 30 parts of water-based epoxy curing agent, 6 parts of trimerization DMP-30 accelerator, 26 parts of high temperature resistant vinyl ester resin paint base, toughening agent 1 part, anti-settling agent 4 parts, mica powder 2 parts, talc powder 3 parts, 600 mesh tungsten metal powder 6 parts, glycerin 28 parts, antimony trioxide 6 parts, magnesium chloride 18 parts.

[0030] The preparation method of above-mentioned chimney climbing ladder with anticorrosion paint, comprises the following steps:

[0031] Step 1. Weigh the raw materials, mix the high temperature resistant vinyl ester resin paint base, toughening agent, anti-settling agent, glycerin, antimony trioxide and magnesium chloride, put them into the reaction kettle, and heat at 4°C / min to 65 °C to obtain the first mixture;

[0032] Step 2, adding mica powder, talc powder and tungsten metal powder into the furnace, he...

Embodiment 3

[0037] A kind of anticorrosion paint for chimney ladder, comprising following raw materials by weight: 38 parts of water-based epoxy curing agent, 8 parts of trimerization DMP-30 accelerator, 29 parts of high temperature resistant type vinyl ester resin paint base, toughening agent 2 parts, 8 parts of anti-settling agent, 4 parts of mica powder, 4 parts of talc powder, 9 parts of 600 mesh tungsten metal powder, 30 parts of glycerin, 8 parts of antimony trioxide, 20 parts of magnesium chloride.

[0038] The preparation method of above-mentioned chimney climbing ladder with anticorrosion paint, comprises the following steps:

[0039] Step 1. Weigh the raw materials, mix the high temperature resistant vinyl ester resin base, toughening agent, anti-settling agent, glycerol, antimony trioxide and magnesium chloride, put them into the reaction kettle, and heat at 5°C / min to 68 °C to obtain the first mixture;

[0040] Step 2, adding mica powder, talc powder and tungsten metal powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com