Multifunctional aqueous printing ink

A water-based ink, multi-functional technology, applied in the direction of ink, household appliances, applications, etc., can solve the problems of ink deterioration, production equipment pollution, pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

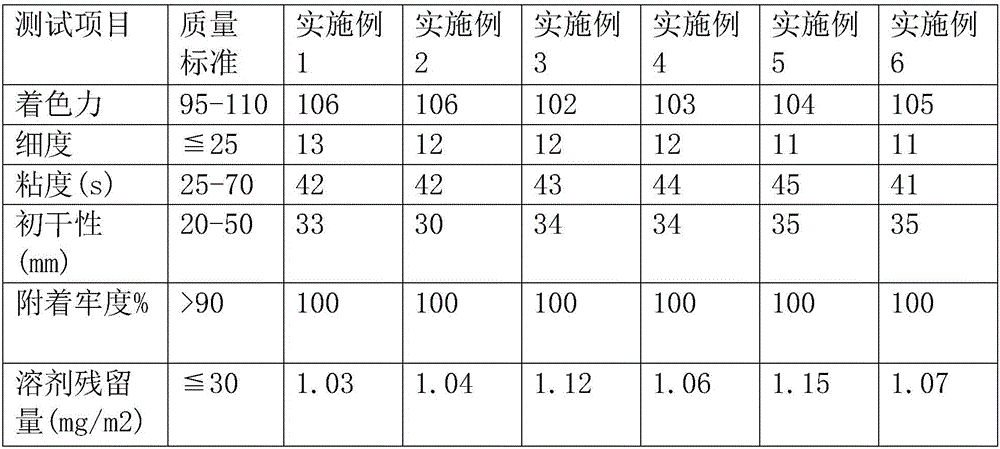

Examples

preparation example Construction

[0022] Preparation of Waterborne Polyurethane Binder

[0023] (1) Raw material pretreatment: first, polyadipate sebacate neopentyl glycol-1,4-butanediol ester diol was decompressed and dehydrated for 1.5h at 85°C and 0.1MPa vacuum, and the The number-average molecular weight of polyadipate sebacate neopentyl glycol-1,4-butanediol ester diol is 2000, and 4,4'-dicyclohexylmethane diisocyanate is dehydrated and dried with activated molecular sieves;

[0024] (2) Preparation of prepolymer: 35 parts by weight of polyadipate sebacate neopentyl glycol-1,4-butanediol ester diol is added in the flask, and the flask is equipped with a stirrer and a condenser , a thermometer and a ventilation tube, feed dry argon into the reaction system, then start the agitator, add 30 parts by weight of diethylenetriamine, then add 5 parts by weight of 4,4'-dicyclohexylmethane diisocyanate and 0.02 parts by weight of bismuth naphthenate, slowly warming up to 75°C, and reacting at a constant temperatur...

Embodiment 1

[0029] 35 parts by weight of waterborne polyurethane;

[0030] 10 parts by weight of polyethylene emulsion;

[0031] 1 part by weight of polyamide wax;

[0032] 0.5 parts by weight of polymethacrylate-styrene copolymer;

[0033] 0.2 parts by weight of hydroxymethylcellulose;

[0034] 0.2 parts by weight of potassium oleate;

[0035] 0.2 parts by weight of 2,6-di-tert-butyl-4-methylphenol;

[0036] 0.5 parts by weight of sodium alkylsulfonate;

[0037] 10 parts by weight of pigment;

[0038] 15 parts by weight of water;

[0039] 5 parts by weight of ethyl acetate;

[0040] 0.3 parts by weight of oregano oil;

[0041] 0.2 parts by weight of Claria essential oil;

[0042] 0.2 parts by weight of tea tree essential oil.

Embodiment 2

[0044] 40 parts by weight of waterborne polyurethane;

[0045] 20 parts by weight of polyethylene emulsion;

[0046] 3 parts by weight of polyamide wax;

[0047] 1 part by weight of polymethacrylate-styrene copolymer;

[0048] 1 weight part of hydroxymethyl cellulose;

[0049] 0.8 parts by weight of potassium oleate;

[0050] 0.6 parts by weight of 2,6-di-tert-butyl-4-methylphenol;

[0051] 1.5 parts by weight of sodium alkylsulfonate;

[0052] 20 parts by weight of pigment;

[0053] 25 parts by weight of water;

[0054] 20 parts by weight of ethyl acetate;

[0055] 0.5 parts by weight of oregano oil;

[0056] 0.4 parts by weight of Claria essential oil;

[0057] 0.3 parts by weight of tea tree essential oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com