A kind of technological method of extracting tannin from Ranunculus yam

A process method, the technology of yam yam, applied in chemical instruments and methods, organic chemistry, sugar derivatives, etc., can solve the problem of low extraction rate of tannin, achieve the effect of shortening the extraction time and increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

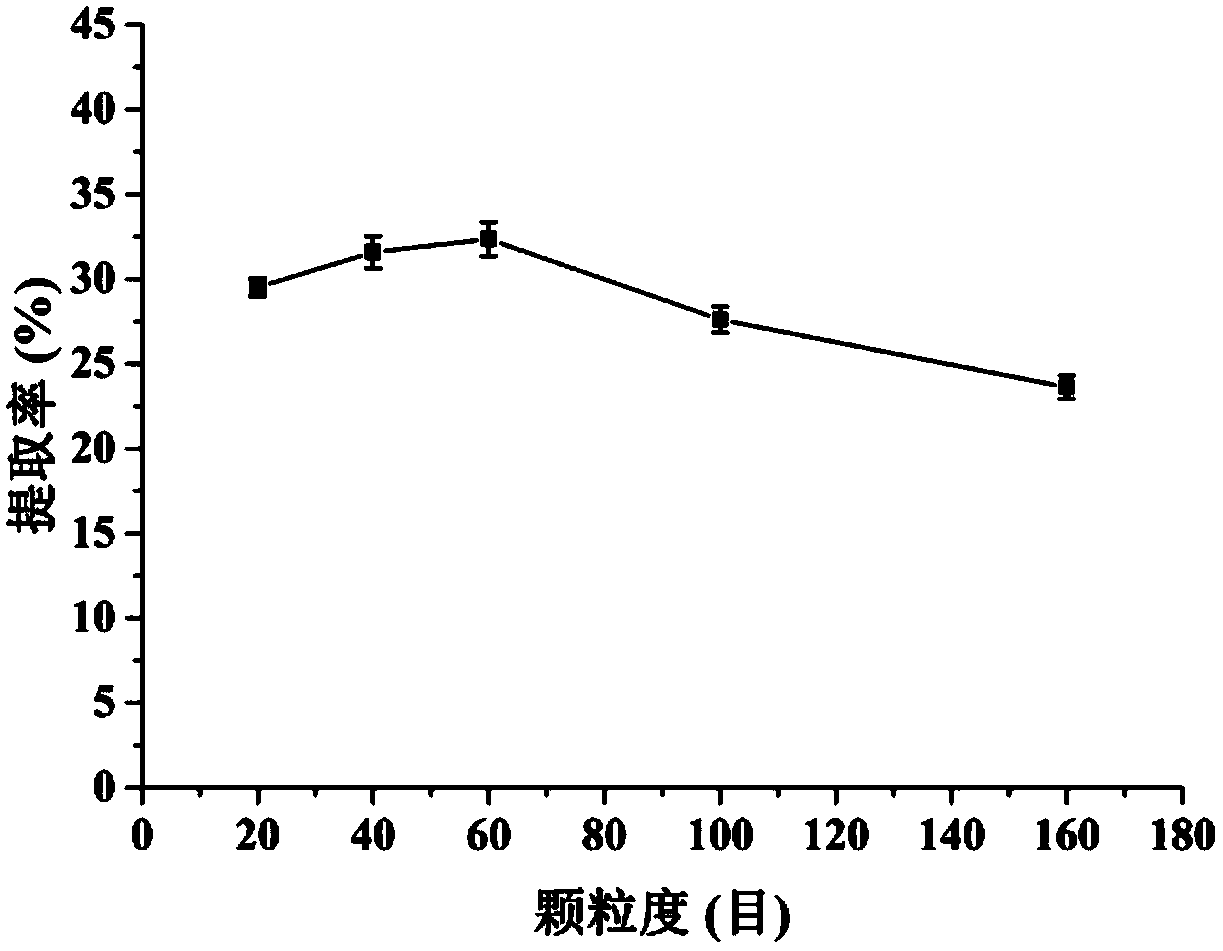

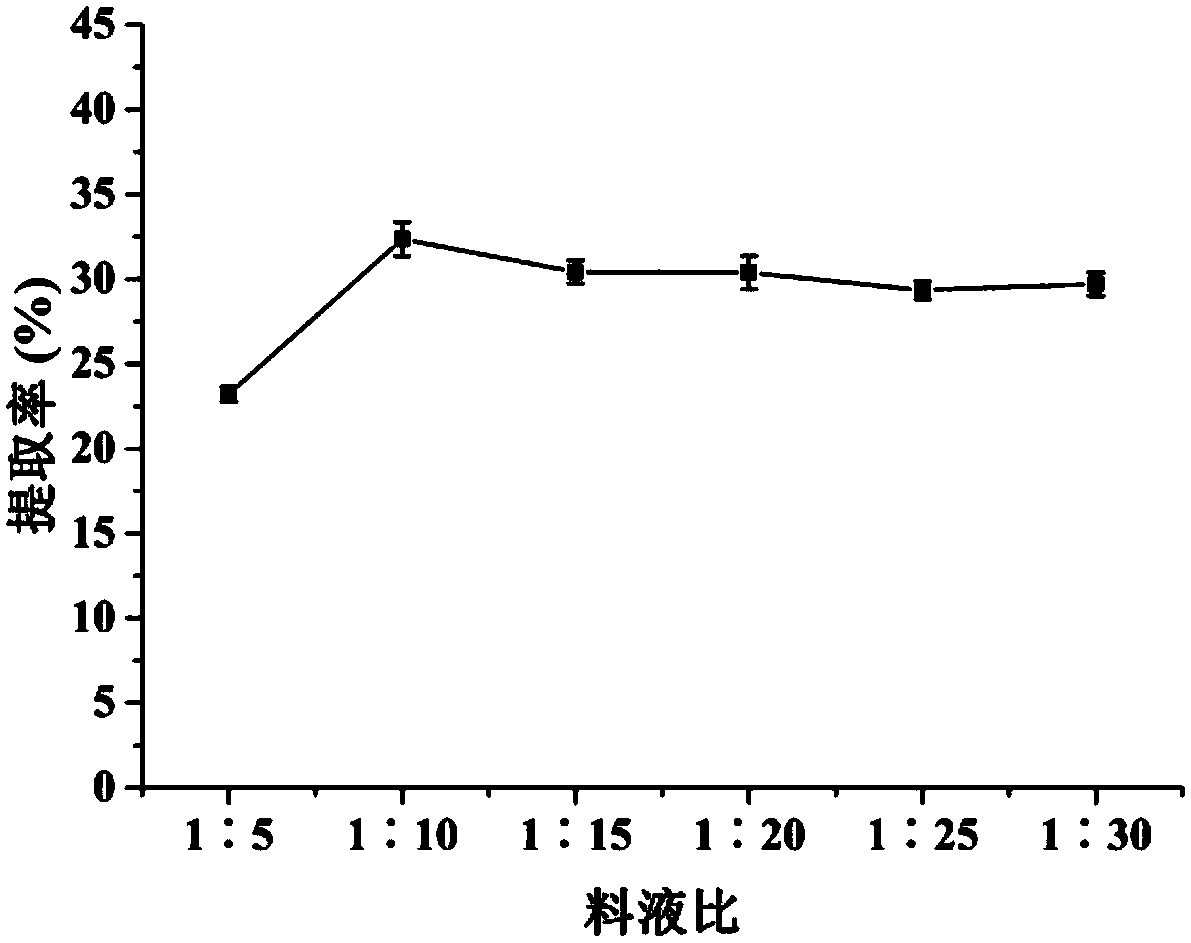

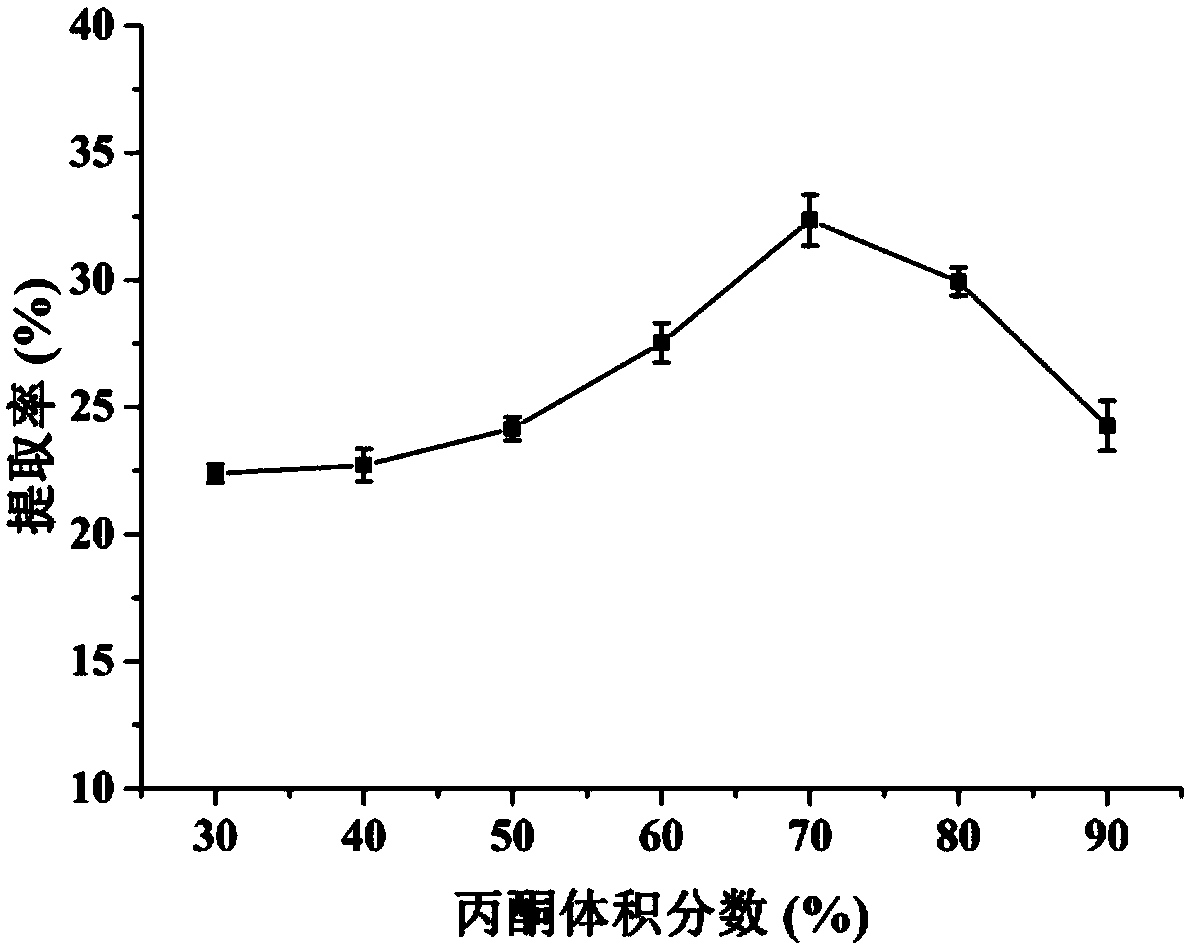

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh 2 g of 40-mesh yam powder into a beaker, add 60% acetone at a solid-liquid ratio of 1:20, set the temperature to 60°C, set the power to 300W, ultrasonically extract for 40 minutes, and filter after cooling to obtain Tannin extract.

[0040] (2) Take 1 mL of the extract and place it in a 100 mL volumetric flask, and dilute to volume with methanol. Take 1mL of the diluted extract, add 6mL of 4% vanillin solution and 3mL of concentrated hydrochloric acid in sequence, cover and shake well, and react in the dark at (25±1)°C for 30min, then measure its maximum absorption wavelength at 500nm Absorbance, the calculated tannin extraction rate is 17.56%.

[0041] (3) Centrifuge the tannin extract for 10 min, distill the supernatant under reduced pressure, and dry it in vacuum. Take 100 mg of the extract and dissolve it with 1 mL of 95% ethanol, separate and purify it with a Sephadex LH-20 column, and first use 400 mL of ethanol at a flow rate of 24 mL / h Elution, and t...

Embodiment 2

[0043] (1) Weigh 2 g of 100-mesh yam powder into a beaker, add 80% acetone at a solid-liquid ratio of 1:15, set the temperature to 40°C, set the power to 180W, ultrasonically extract for 20 minutes, and filter after cooling to obtain Tannin extract.

[0044] (2) Take 1 mL of the extract and place it in a 100 mL volumetric flask, and dilute to volume with methanol. Take 1mL of the diluted extract, add 6mL of 4% vanillin solution and 3mL of concentrated hydrochloric acid in turn, cover and shake well, and react in the dark at (25±1)°C for 30min, then measure its maximum absorption wavelength at 500nm Absorbance, the calculated tannin extraction rate is 20.08%.

[0045] (3) Centrifuge the tannin extract for 10 min, distill the supernatant under reduced pressure, and dry it in vacuum. Take 100 mg of the extract and dissolve it with 1 mL of 95% ethanol, separate and purify it with a Sephadex LH-20 column, and first use 400 mL of ethanol at a flow rate of 24 mL / h Elution, and then...

Embodiment 3

[0047] (1) Weigh 2g of 60-mesh yam powder into a beaker, add 70% acetone at a material-to-liquid ratio of 1:10, set the temperature to 50°C, set the power to 240W, ultrasonically extract for 30 minutes, and filter after cooling to obtain Tannin extract.

[0048](2) Take 1 mL of the extract and place it in a 100 mL volumetric flask, and dilute to volume with methanol. Take 1mL of the diluted extract, add 6mL of 4% vanillin solution and 3mL of concentrated hydrochloric acid in sequence, cover and shake well, and react in the dark at (25±1)°C for 30min, then measure its maximum absorption wavelength at 500nm Absorbance, the calculated tannin extraction rate is 31.45%.

[0049] (3) Centrifuge the tannin extract for 10 min, distill the supernatant under reduced pressure, and dry it in vacuum. Take 100 mg of the extract and dissolve it with 1 mL of 95% ethanol, separate and purify it with a Sephadex LH-20 column, and first use 400 mL of ethanol at a flow rate of 24 mL / h Elution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com