Boiler sewage recovery and treatment process combined with reverse osmosis and chemical precipitation technology

A chemical precipitation and recycling technology, applied in flocculation/sedimentation water/sewage treatment, neutralized water/sewage treatment, water/sewage treatment, etc. Water quality is difficult to control and other problems, to achieve the effect of saving high-quality water resources, saving sludge disposal costs, and high ion removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A recovery and treatment process of boiler blowdown water combined with reverse osmosis and chemical precipitation technology, the process is realized by means of a recovery treatment device for boiler blowdown water:

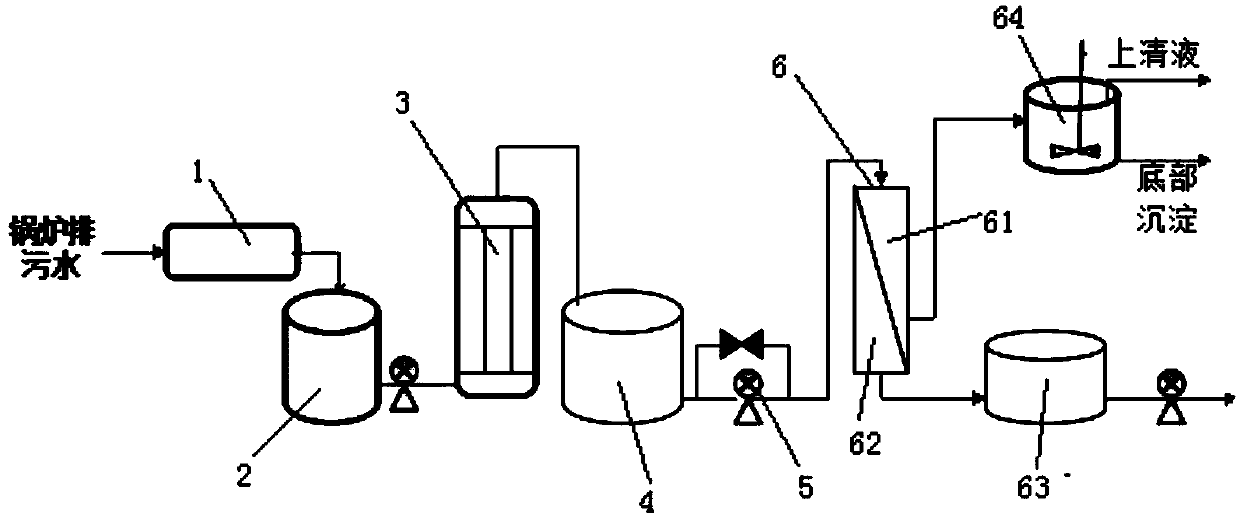

[0041] The described recovery treatment device comprising boiler effluent comprises water cooler 1, buffer tank 2, precision filter 3 and reverse osmosis system 6 connected in sequence, the concentrated liquid side 61 of the reverse osmosis membrane in the reverse osmosis system 6 and the chemical sedimentation tank 64 connection, the permeate side 62 is connected to the permeate pool 63, and an intermediate water tank 4 and a high-pressure pump 5 are arranged in sequence between the precision filter 3 and the reverse osmosis system 6, such as figure 1 shown.

[0042] Taking the treatment of sewage from the boiler blowdown cooling tank of a natural gas company in Sichuan as an example, the process is further explained.

[0043] (1) The total sewage disc...

Embodiment 2

[0047] A recovery and treatment process of boiler effluent water combined with reverse osmosis and chemical precipitation technology, which is realized by means of a recovery treatment device for boiler effluent water which is basically the same as that in Embodiment 1.

[0048] Taking the treatment of MB boiler sewage from a large paper mill in Qinzhou, Guangxi as an example, the specific implementation steps are as follows:

[0049] (1) will be about 113m 3 / h Boiler sewage, after being cooled by the water cooler, add hydrochloric acid to adjust the pH to 7.60, and send the mixed sewage sewage of the cooling pool to the precision filter (the preferred pp filter element filter in this embodiment) through the clean water pump, and the flow rate of the filter is designed Output is 120m 3 / h, the filter effluent SDI is less than 3.0.

[0050] (2) Filter the water from step (1) and send it into the reverse osmosis system through a booster pump. The design output of the reverse ...

Embodiment 3

[0054] A recovery and treatment process of boiler effluent water combined with reverse osmosis and chemical precipitation technology, which is realized by means of a recovery treatment device for boiler effluent water which is basically the same as that in Embodiment 1.

[0055] Taking the treatment of power boiler sewage from a petrochemical enterprise in Dazhou, Sichuan as an example, the implementation steps are as follows:

[0056] (1) will be about 69m 3 / h The boiler blowdown water enters the blowdown cooling pool after being cooled by the water cooler. Add sulfuric acid to adjust the pH to 7.51. It is transported by the pump to the pp filter element security filter for filtration, and the design output of the flow rate of a single filter is 45m 3 / h, the filter effluent SDI is less than 3.0.

[0057] (2) Filter the water from step (1) and send it into the reverse osmosis system through a high-pressure pump. The design output of reverse osmosis system is 75m 3 / h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com