Method for preparing aluminum nitride powder

A technology of aluminum nitride and powder, which is applied in the field of preparation of aluminum nitride powder, and can solve the problems of affecting the purity of powder, incomplete nitriding, incomplete reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

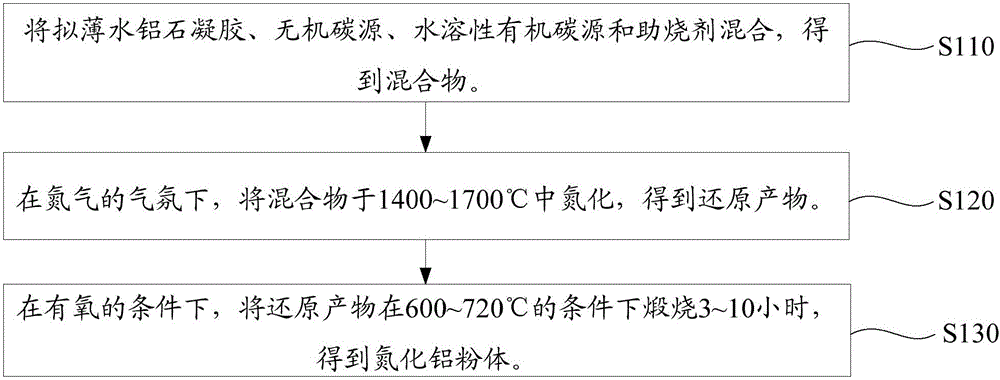

[0025] Such as figure 1 Shown, the preparation method of the aluminum nitride powder of one embodiment, comprises the following steps:

[0026] Step S110: Mix pseudo-boehmite gel, inorganic carbon source, water-soluble organic carbon source and sintering aid to obtain a mixture.

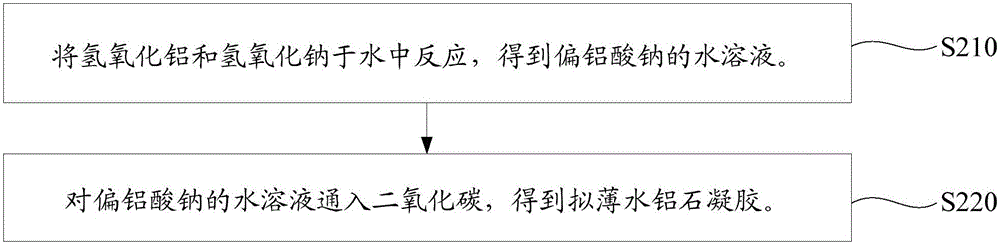

[0027] Wherein, the mass percent content of the pseudo-boehmite gel is 5-30%. Pseudo-boehmite gel can be purchased from the market or prepared. Such as figure 2 Shown, the preparation method of pseudo-boehmite gel is as follows:

[0028] Step S210: reacting aluminum hydroxide and sodium hydroxide in water to obtain an aqueous solution of sodium metaaluminate.

[0029] The steps of reacting aluminum hydroxide and sodium hydroxide in water are as follows: according to the volume to mass ratio of 10 milliliters: 2 grams to 6 grams, adding aluminum hydroxide to an aqueous solution of sodium hydroxide with a concentration of 10 to 40% by mass , Stir the reaction at 90-110°C to obtain an aqueous solu...

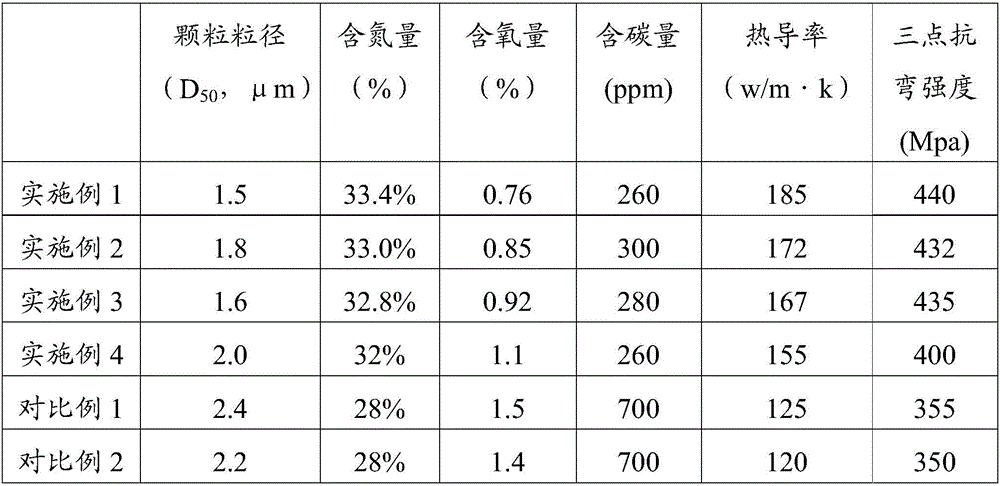

Embodiment 1

[0049] The preparation process of the aluminum nitride powder of the present embodiment is as follows:

[0050](1) Preparation of pseudoboehmite gel: according to the volume to mass ratio of 10 milliliters: 4 grams, aluminum hydroxide is added to an aqueous solution of 25% sodium hydroxide by mass percentage, and stirred at 100 ° C React to obtain an aqueous solution of sodium metaaluminate; at 40°C, pass carbon dioxide into the aqueous solution of sodium metaaluminate for 50 minutes, neutralize to a pH value of 11, and then dropwise add mass at a rate of 1 drop in 3 minutes The percentage concentration is 5% ammonia water, continue to pass into carbon dioxide until the pH value is 9, obtain the pseudo-boehmite gel that the mass percentage content of pseudo-boehmite is 25%, wherein, the feeding flow rate of carbon dioxide is 8Nm 3 / h.

[0051] (2) Mix pseudo-boehmite gel, inorganic carbon source, water-soluble organic carbon source and sintering aid by ball milling to make p...

Embodiment 2

[0057] The preparation process of the aluminum nitride powder of the present embodiment is as follows:

[0058] (1) Preparation of pseudo-boehmite gel: according to the volume to mass ratio of 10 milliliters: 2 grams, adding aluminum hydroxide to a 10% aqueous sodium hydroxide solution by mass percentage, stirring and reacting at 90°C, Obtain an aqueous solution of sodium metaaluminate; under the condition of 25°C, pass carbon dioxide into the aqueous solution of sodium metaaluminate for 120 minutes, neutralize until the pH value is 10, and then add the mass percent dropwise at a rate of 1 drop in 5 minutes Concentration is 5% ammonia water, continues to feed carbon dioxide until the pH value is 8.5, obtains the pseudo-boehmite gel that the mass percentage content of pseudo-boehmite is 5%, wherein, the feeding flow rate of carbon dioxide is 2Nm 3 / h.

[0059] (2) Ball milling and mixing pseudo-boehmite gel, inorganic carbon source, water-soluble organic carbon source and sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com