Preparation method for metallic cobalt microspheres

A technology of metal cobalt and microspheres, applied in metal processing equipment, transportation and packaging, etc., to achieve the effect of enhancing automatic production, reducing energy consumption, and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

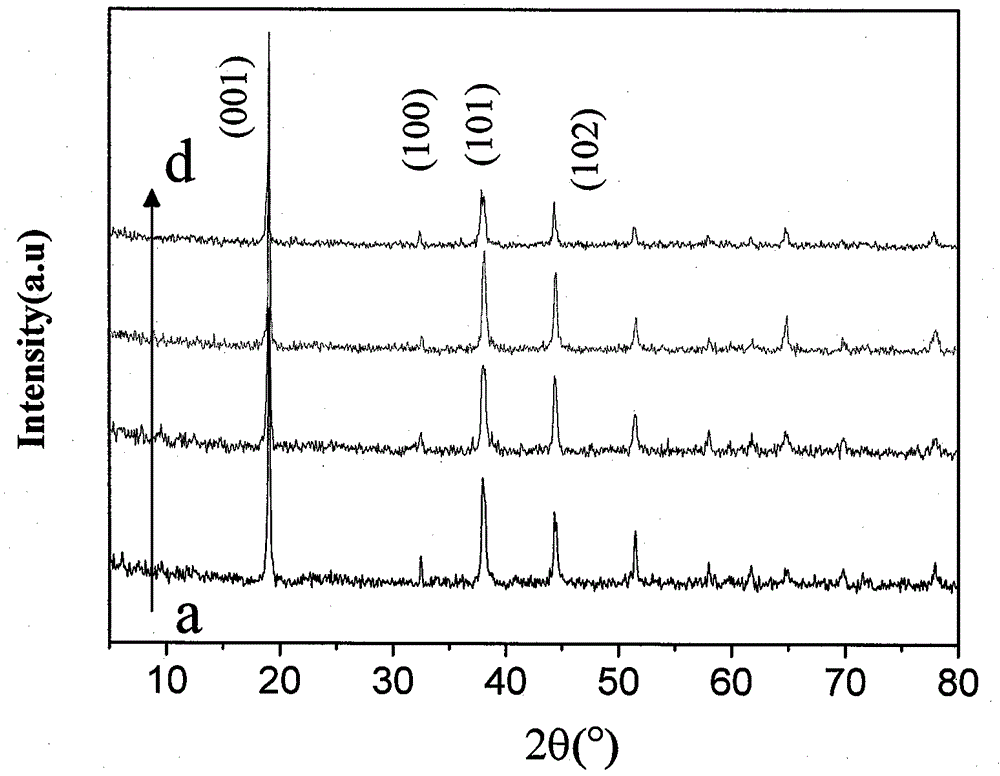

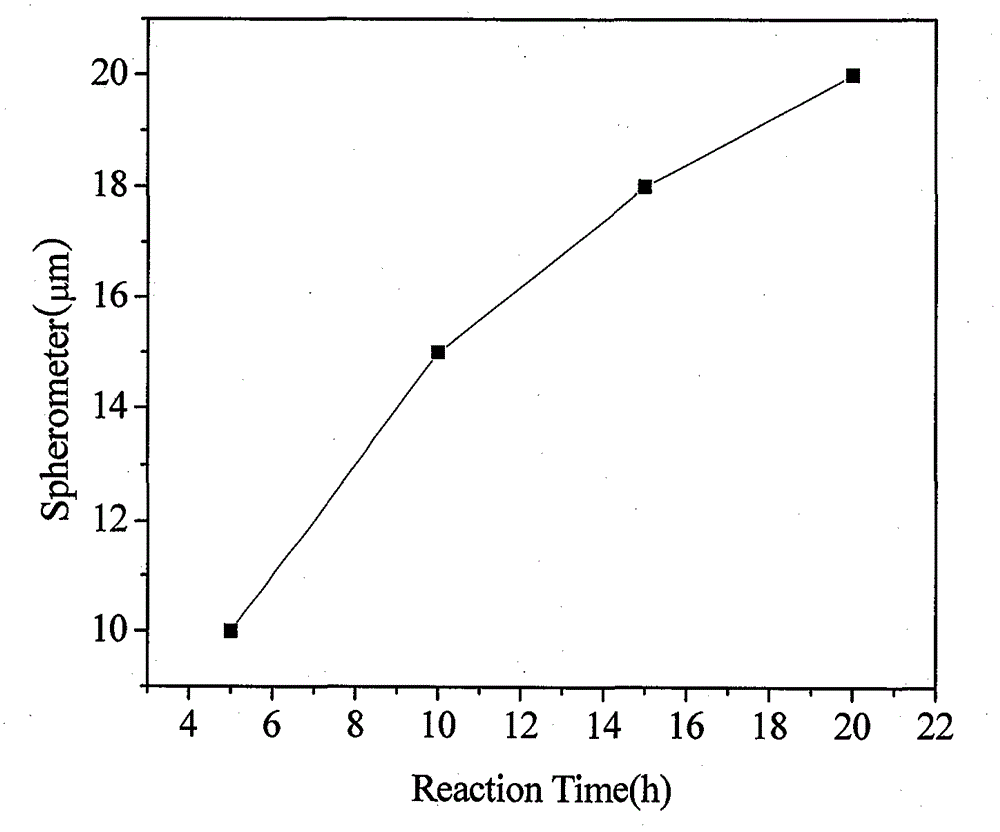

[0033] A preparation method of metal cobalt microspheres provided by the present invention comprises the following four key process steps.

[0034] The first step is to prepare micron-sized spherical cobalt hydroxide by hydrothermal method. The preparation of various forms of nano-micron cobalt hydroxide by hydrothermal method has been generally recognized. The key to preparing spherical cobalt hydroxide is to carry out the precipitation and dissolution equilibrium of cobalt hydroxide in the system gently, that is, to control the reasonable pH value and the concentration of cobalt ions in the solution at a lower temperature. In this process, there are cobalt ions, ammonium ions, hydroxide ions, EDTA, ammonia molecules, cobalt hydroxide and other substances in the solution, and there are various reaction balances between the above molecules or ions, and complex ions are generated. By calculating the corresponding equilibrium coefficients and complexation equilibrium constants,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com