Rolling mill for three-layer compounded micro-profiled electric contact strip

A micro-shape, electric contact technology, applied in the direction of liquid cleaning method, furnace type, metal rolling, etc., can solve the problems of production difficulty, etc., achieve simple and convenient adjustment, improve annealing effect, and ensure the effect of composite quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

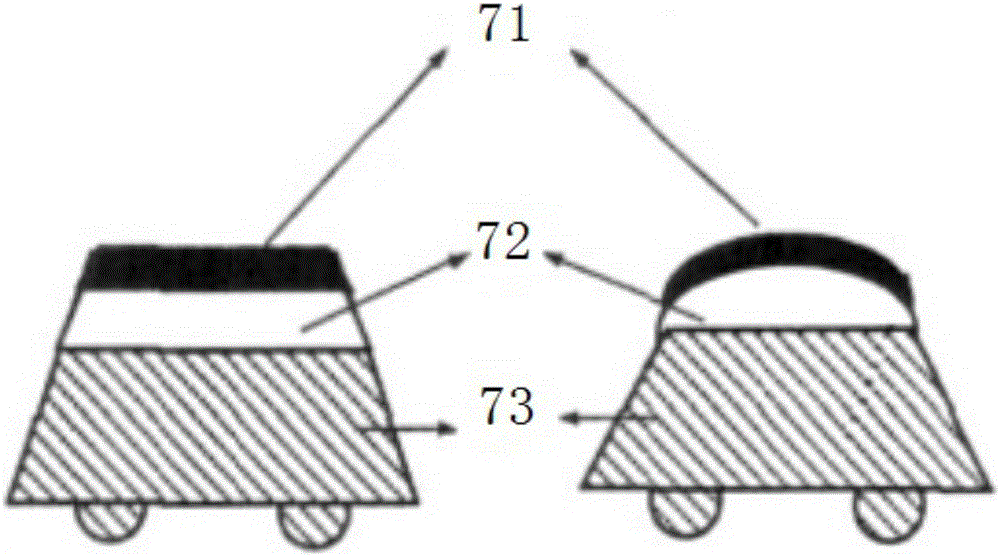

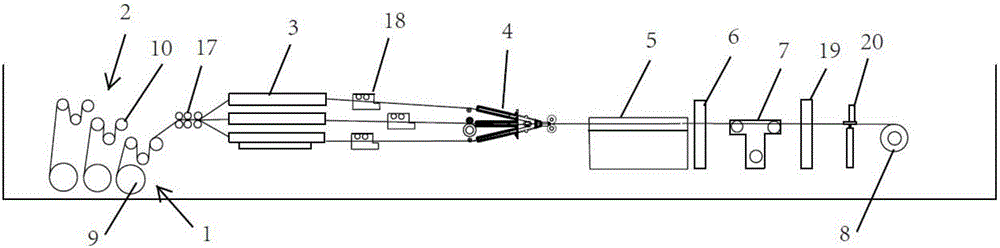

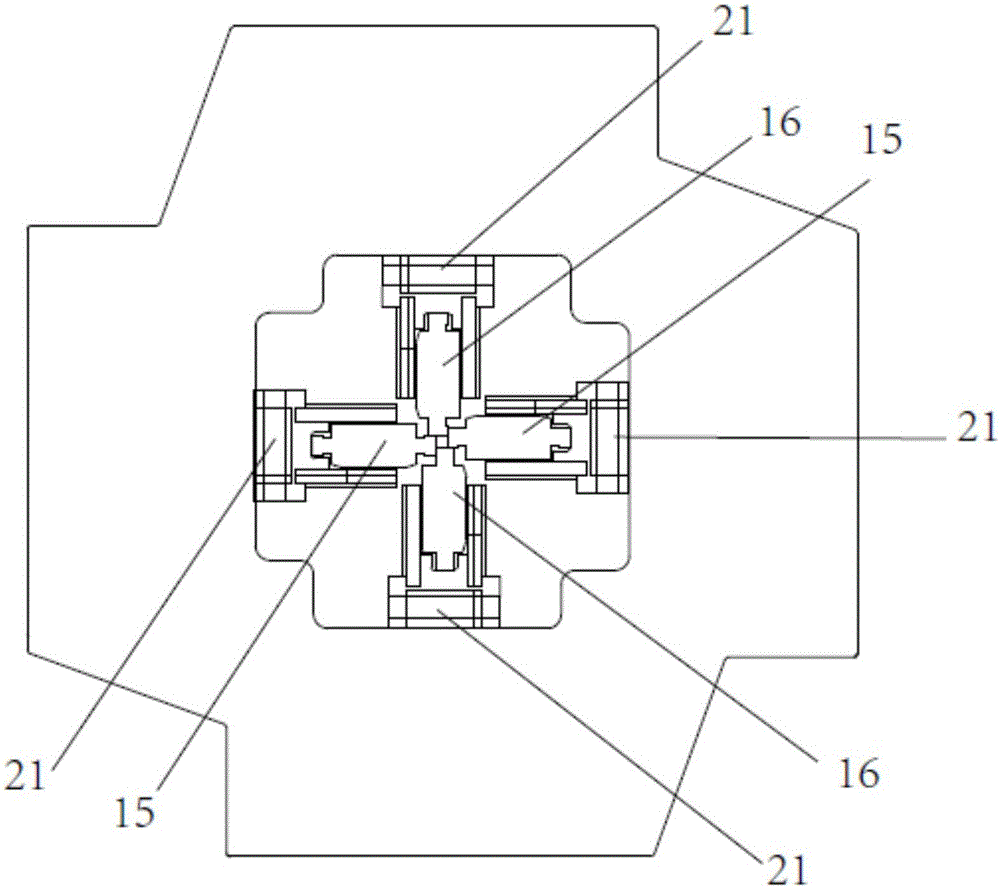

[0058] When the above-mentioned rolling mill is actually processing the strip, it is illustrated by taking the preparation of a silver-copper-silver three-layer lateral composite strip with a height of 1.2mm and a width of 2.5mm as an example:

[0059] 1. The pay-off department adopts a pull-type tension sensor to collect and feed back the tension data of the two silver strips (length 60m, width 1mm, height 2mm) and the base copper strip (length 60m, width 5mm, height 2mm) that need to be rolled and compounded. To the PLC main controller to control the pay-off motor;

[0060] 2. The straightening device ensures that the two silver strips and the base copper strip run smoothly and synchronously, ensuring the smooth transition of the strip before entering the compound rolling mill;

[0061] 3. The cleaning tank uses ultrasonic cleaning to clean the two silver strips, uses 5% H2SO4 acid solution to clean the copper strips, and decontaminates the surface of the three metal strips ...

specific Embodiment 2

[0071] The difference between the specific embodiment two and the specific embodiment one is that the preparation height is 1mm, and the silver-kovar alloy (KOVAR alloy)-silver three-layer lateral composite strip with a width of 3 mm adopts 15% H2SO4 acid solution Clean the Kovar alloy, and preheat the Kovar alloy to 800°C. It can also be easily produced by using this rolling mill.

[0072] This rolling mill makes three metal strips rolled and compounded at one time through large plastic deformation. The surface quality of the compounded strips is good and the bonding strength is high; the process of rolling multiple lateral composite strips is continuous and compact, and the adjustment is simple and convenient. The production speed is fast and the product quality is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com