Ultrasonic standing wave type microfluidic chip and manufacturing method thereof

A microfluidic chip and ultrasonic standing wave technology, applied in the field of microfluidics, can solve the problems of manipulating short nanofiber wires, achieve good shape, good effect, and have the effect of ultrasonic standing wave response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

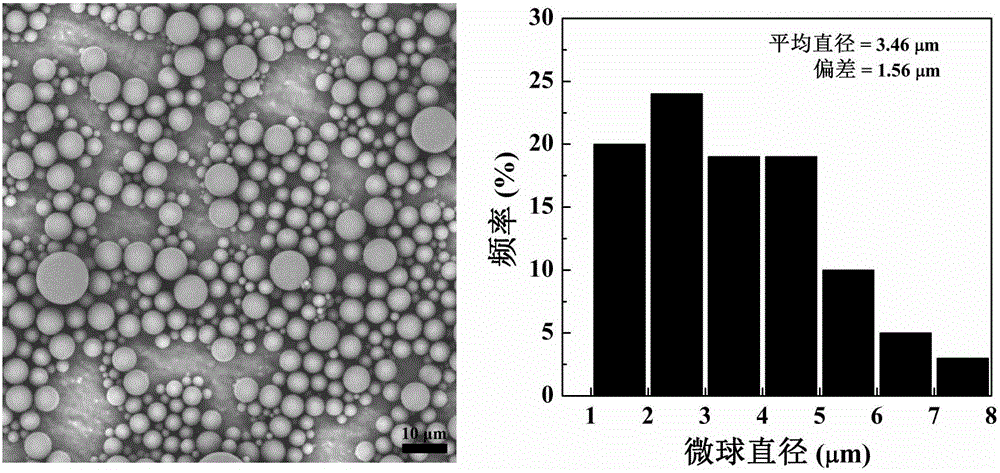

[0053] The specific process of preparation and functional modification of PLGA microspheres is as follows:

[0054] (1) Weigh 100mg PLGA and dissolve in 2mLCH 2 Cl 2 200μL of ultrapure water as the inner water phase, mix the organic phase and the inner water phase, and ultrasonically treat for 30s in an ice-water bath to form a W / O emulsion; transfer the above W / O emulsion into 50mL of 5% PVA aqueous solution In the state of ice-water bath, use a homogenizer (6000rpm, 5min) to make the droplets form a W / O / W emulsion with a relatively uniform size; drop the obtained W / O / W emulsion into 80mL of 2% isopropanol aqueous solution , under the condition of 39°C water bath, after magnetic stirring for 4h, centrifuge (4000rpm, 3min), discard the supernatant, wash the centrifuged residue with 30mL ultrapure water, repeat the above centrifugal washing operation three times until the supernatant is clear and colorless, After centrifugation, the centrifuged residue was redispersed in 30ml...

Embodiment 2

[0059] Ultrasonic standing wave microfluidic chip such as Figure 12 As shown, the specific steps are as follows:

[0060] (1) at 76×26mm 2 On the glass slide, fix the rectangular capillary (length is 50mm, width is 0.2mm, height is 2mm) with epoxy resin glue, this rectangular capillary is used as the channel of microfluidic chip;

[0061] (2) At the outlets on both sides of the rectangular capillary, a polyethylene tube with an inner diameter of 1 mm and an outer diameter of 1.4 mm is used as the input port and the output port of the suspension;

[0062] (3) Finally, on the side of the fixed rectangular capillary, fix the piezoelectric ceramic sheet (15mm×2mm×0.2mm) by epoxy resin bonding, and then weld the wires on the front and back of the piezoelectric ceramic sheet as the circuit connection wire .

[0063] Take 2mL of the aqueous solution (0.2mg / mL) of the product obtained in (1) in Example 1 and place it in a 5mLEP tube as a liquid storage tube. Before the test, the m...

Embodiment 3

[0065] Take 500 μL (1 mg) of the PLGA-PEI aqueous solution of the product obtained in (2) in Example 1, dilute it to 1 mL (concentration is 0.5 mg / mL) with a serum-free medium, place it in a 5 mLEP tube, and add the serum-free solution that has been digested and centrifuged. HeLa cells (1 million) suspended in the culture medium, with a total volume of 2 mL, were co-cultured at 37° C. for 30 min to obtain a solution of cell-microsphere conjugates. Before the test, the microfluidic chip was soaked in 2% BSA for 2 hours, and the ultrasonic standing wave microfluidic device platform was built. First, it was tested whether the voltage was applied to both ends of the piezoelectric ceramic, and the output signal of the signal generator was adjusted to a voltage of 20Vpp. , the frequency is 10KHz, the standard is that you can hear a buzzing sound after adding this signal, otherwise there will be no signal at both ends of the piezoelectric ceramic, then you need to check whether the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com