A device and method for treating nitrogen oxides in condensed acid

A technology of nitrogen oxides and spraying devices, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problem of exceeding the standard; it may also enter the finished sulfuric acid, the quality of the finished acid is unqualified, and a large amount of brown smoke appears, etc. problems, to achieve the effect of improving the working environment, operating cost economy, and preventing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

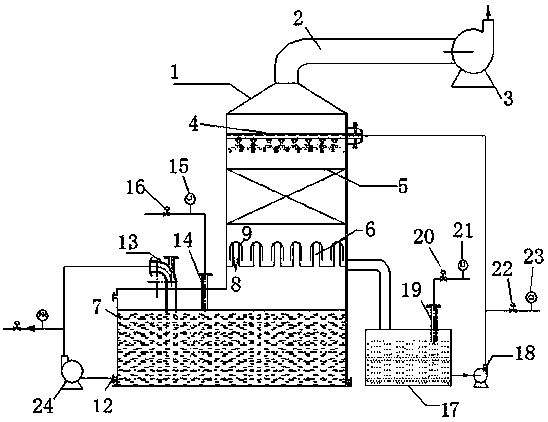

[0027] Add condensed acid and water to the mixing tank in a volume ratio of 1:3. The mixing tank is filled with clean water to 3.1 meters. The condensed acid enters the mixing tank after mixing the acid through the acid mixer, and releases a large amount of nitrogen oxides after fully mixing with water ; Add a urea solution with a concentration of 21.5% and water in a volume ratio of 1:2 into the absorption liquid circulation tank to configure a 7.6% dilute solution, and the liquid level is controlled at 3 meters.

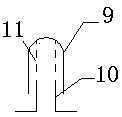

[0028] Start the fan, the condensed acid and water will be fully mixed and release a large amount of nitrogen oxides. With the slight negative pressure (-3.4KPa) of the fan, it will escape to the upper part of the spray absorption tower through the liquid barrier; start the absorption pump to absorb The liquid is transported to the tube-tank liquid separator in the spray absorption tower, and the tube-tank liquid separator is started to spray the absorption liquid down...

Embodiment 2

[0030] Add condensed acid and water to the mixing tank at a volume ratio of 1:2.5. The mixing tank is filled with clean water to 3.15 meters. The condensed acid enters the mixing tank after mixing the acid through the acid mixer, and releases a large amount of nitrogen oxides after fully mixing with water ; Add 18.5% urea solution and water in a volume ratio of 1:1 into the absorption liquid circulation tank to form an 8.5% dilute solution, and the liquid level is controlled at 3 meters.

[0031] Start the fan, the condensation acid and water will release a large amount of nitrogen oxides, and the slight negative pressure (-3.6KPa) of the fan will escape upward through the liquid septum to the upper part of the spray absorption tower, and be absorbed by the urea solution; start The absorption pump transports the absorption liquid to the spray device in the spray absorption tower. The absorption liquid is in countercurrent contact with the nitrogen oxide gas, and the nitrogen oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com