Extraction method for dissolved-regenerated lignin

An extraction method and lignin technology, applied in lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of difficulty, complex lignin extraction process, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

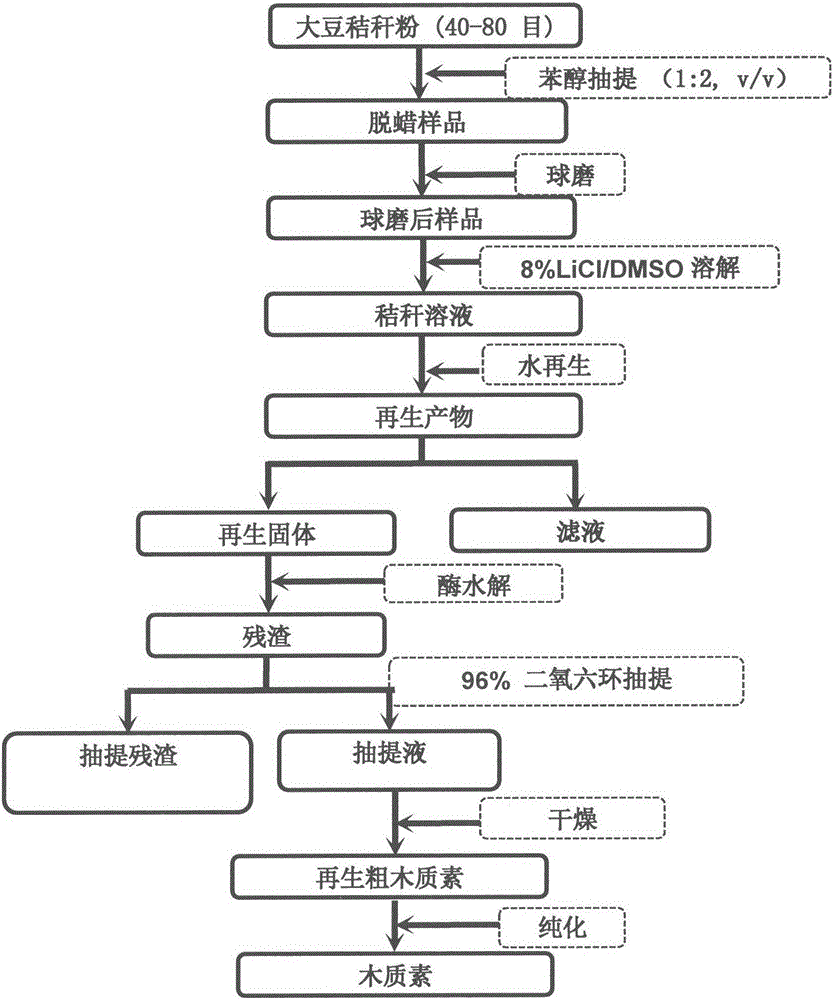

Method used

Image

Examples

Embodiment 1

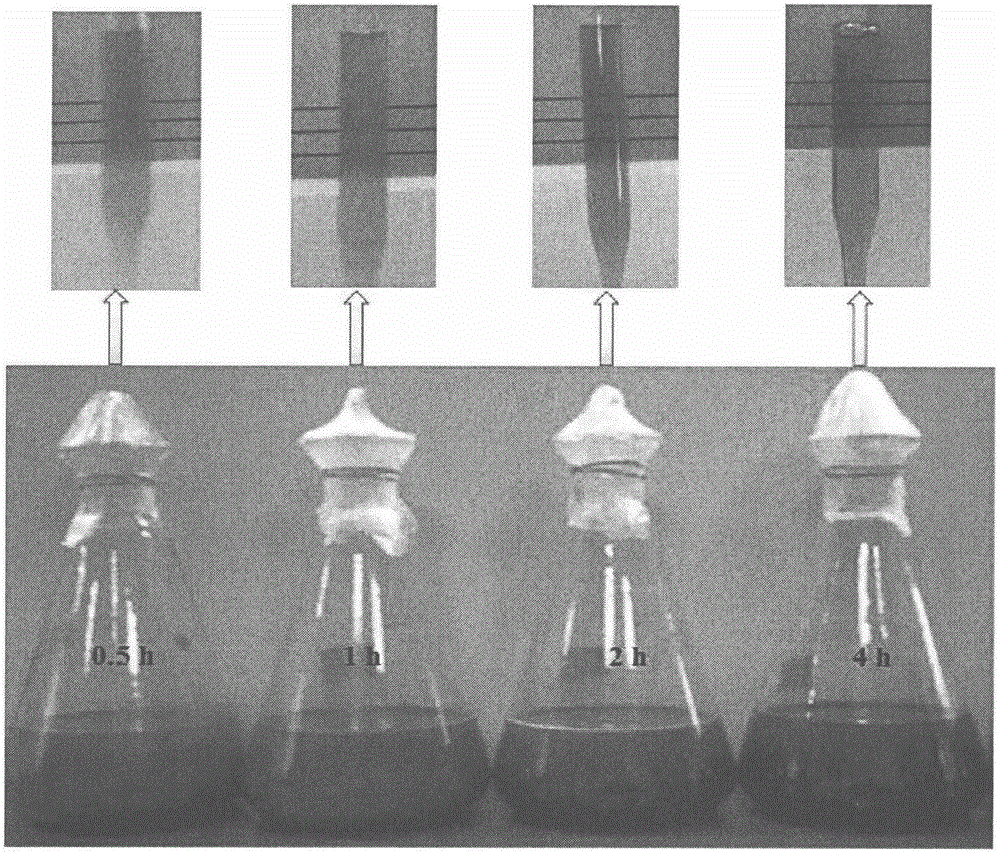

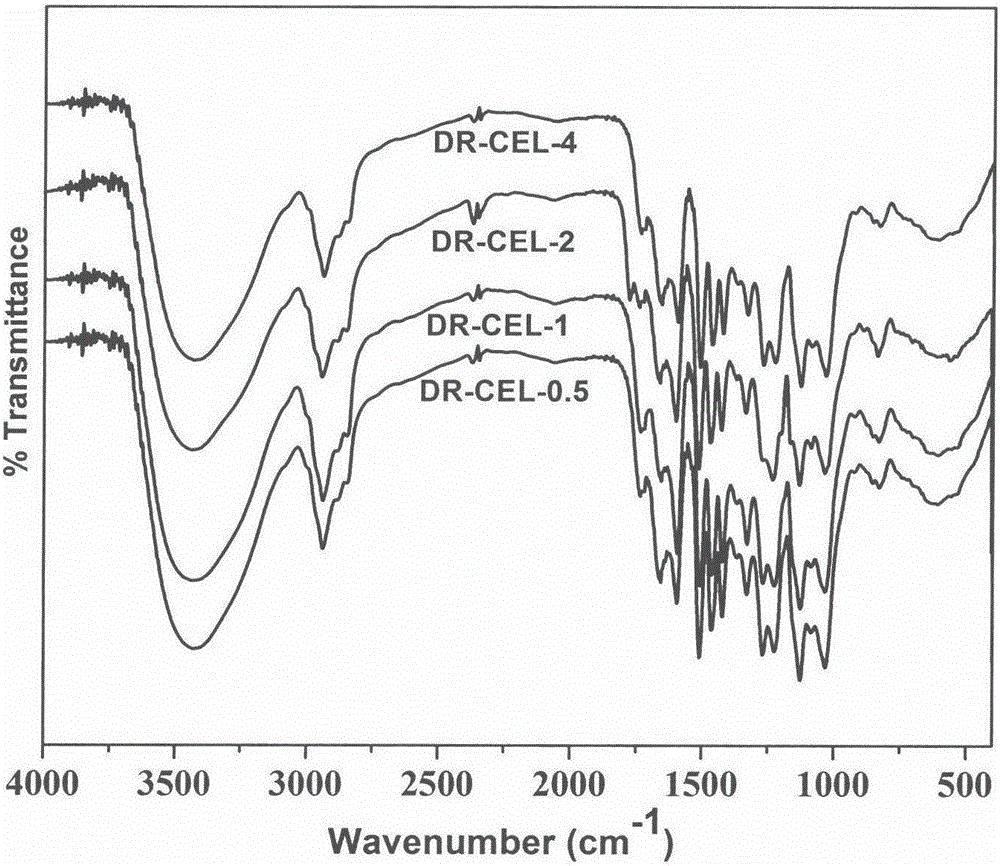

[0032] (1) Take the stalk part of the soybean stalk, pulverize it with a miniature plant grinder, and then process it with a planetary ball mill for 0.5 h to obtain lignocellulose powder;

[0033] (2) Weigh 5g of powder processed by ball mill for 0.5h, then dissolve it in 8% LiCl / DMSO lignocellulose total solution system with 5% concentration, and after magnetic stirring at room temperature for 24h, amber clear and translucent lignocellulose / LiCl / DMSO solution;

[0034] (3) Add the lignocellulose / LiCl / DMSO solution dropwise to 5 times the volume of distilled water, stir and disperse evenly, let it stand for a while, centrifuge the regenerated lignocellulose product and wash it with distilled water until AgNO 3 Check for Cl - exist;

[0035] (4) After washing the lignocellulose dissolving-regenerated product with distilled water, directly add it in the acetic acid-sodium acetate buffer solution with a pH value of 4.8, and then add 400FPU Commercial enzymes;

[0036] (5) R...

Embodiment 2

[0041] (1) Take the stalk part of the soybean stalk, pulverize it with a miniature plant grinder, and then process it with a planetary ball mill for 1.0 h to obtain lignocellulose powder;

[0042] (2) Weigh 5g of powder processed by ball mill for 1.0h, then dissolve it in 8%LiCl / DMSO wood fiber total solution system with 5% concentration, and after magnetic stirring at room temperature for 24h, amber clear and translucent lignocellulose / LiCl / DMSO solution;

[0043] (3) Add the lignocellulose / LiCl / DMSO solution dropwise to 5 times the volume of distilled water, stir and disperse evenly, let it stand for a while, centrifuge the regenerated lignocellulose product and wash it with distilled water until AgNO 3 Check for Cl - exist;

[0044] (4) After washing the lignocellulose dissolving-regenerated product with distilled water, directly add it in the acetic acid-sodium acetate buffer solution with a pH value of 4.8, and then add 400FPU commercial enzymes,

[0045] (5) Regula...

Embodiment 3

[0050] (1) Take the stalk part of the soybean stalk, pulverize it with a miniature plant grinder, and then process it with a planetary ball mill for 2.0 hours to obtain lignocellulose powder;

[0051] (2) Weigh 5g of powder processed by ball mill for 2.0h, then dissolve it in 8%LiCl / DMSO lignocellulose total solution system with 5% concentration, and after magnetic stirring at room temperature for 24h, amber clear and translucent lignocellulose / LiCl / DMSO solution;

[0052] (3) Add the lignocellulose / LiCl / DMSO solution dropwise to 5 times the volume of distilled water, stir and disperse evenly, let it stand for a while, centrifuge the regenerated lignocellulose product and wash it with distilled water until AgNO 3 Check for Cl - exist;

[0053] (4) After washing the lignocellulose dissolving-regenerated product with distilled water, directly add it in the acetic acid-sodium acetate buffer solution with a pH value of 4.8, and then add 400FPU commercial enzymes,

[0054] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com