Box type transformer station current-carrying fault prediction system and application thereof

A box-type substation and fault prediction technology, applied in information technology support systems, electrical components, circuit devices, etc., can solve the problems of weak equipment interoperability, easy interference of collected signals, and singular points, etc., to achieve fast data processing Capabilities and the effect of real-time monitoring capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

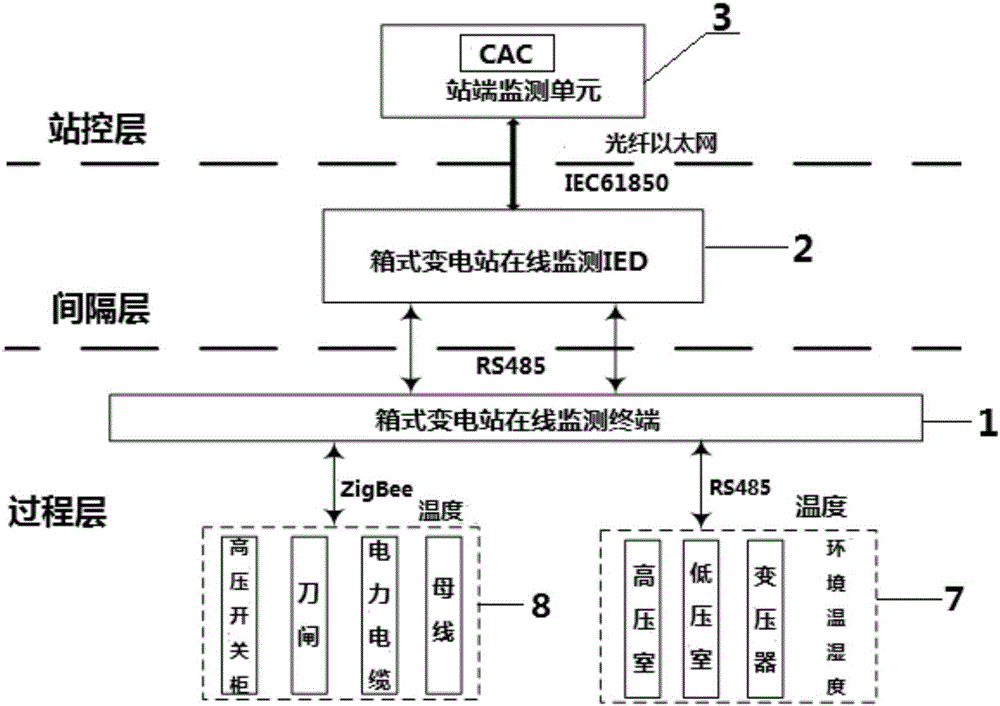

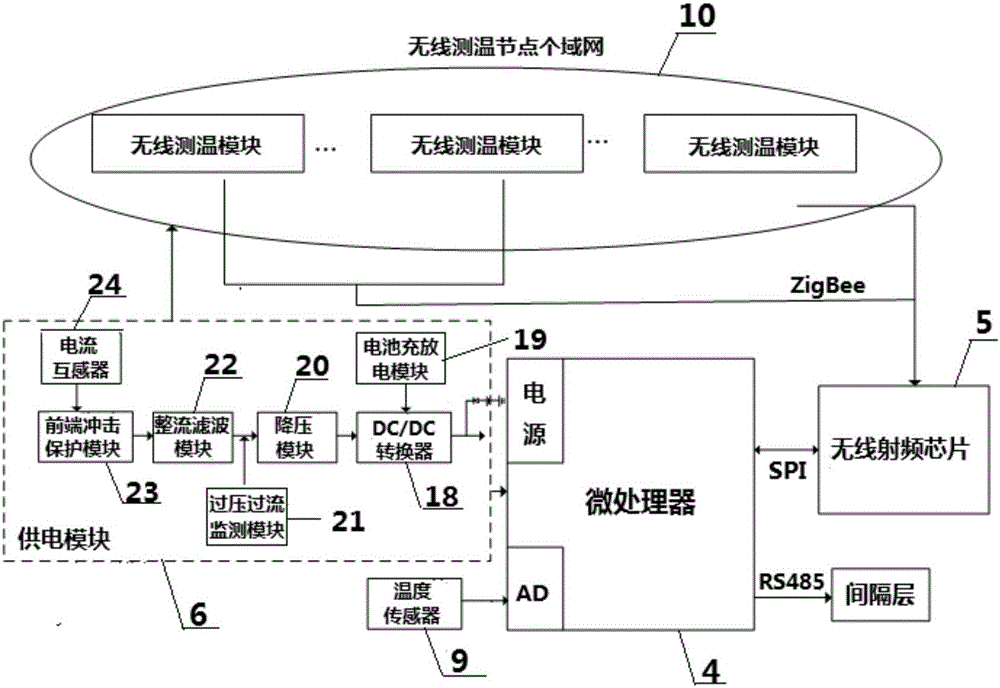

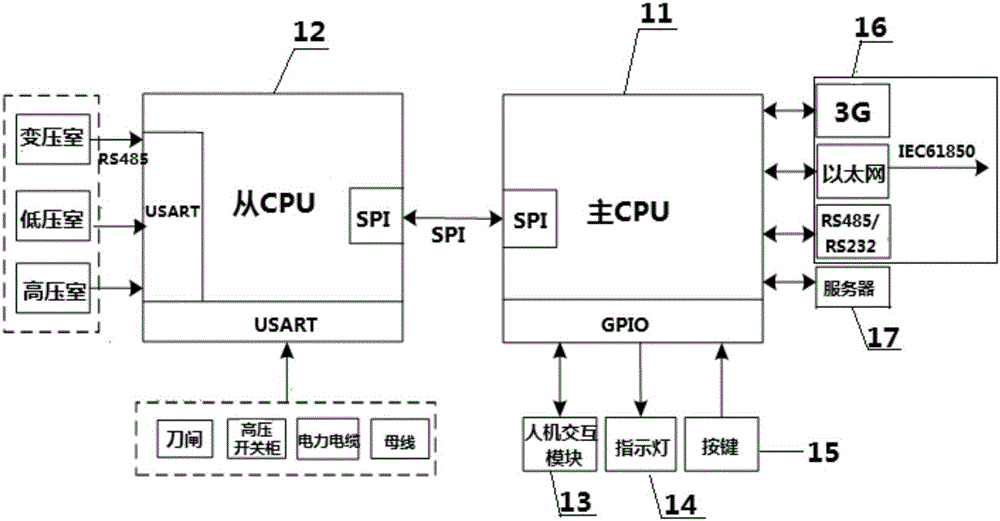

[0062] The box-type substation current-carrying fault prediction system of the present invention, such as figure 1 As shown, it includes the process layer, the interval layer and the station control layer; the process layer is equipped with a box-type substation on-line monitoring terminal 1, and the box-type substation on-line monitoring terminal 1 is connected to the temperature measurement point 7 of the wired temperature measurement module through the RS485 bus. The on-line monitoring terminal 1 of the substation is also connected to the temperature measurement point 8 of the wireless temperature measurement module through the Zigbee wireless personal area network; the on-line monitoring IED2 of the box-type substation is set in the interval layer, and the on-line monitoring IED2 of the box-type substation is connected to the box-type subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com