Glass plate packaging container and transport method using the same

A technology for packaging containers and glass plates, which is applied in the direction of containers, packaging, rigid containers, etc. It can solve the problems that large glass substrates cannot be transported horizontally, and achieve the effect of reducing swing and efficient transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

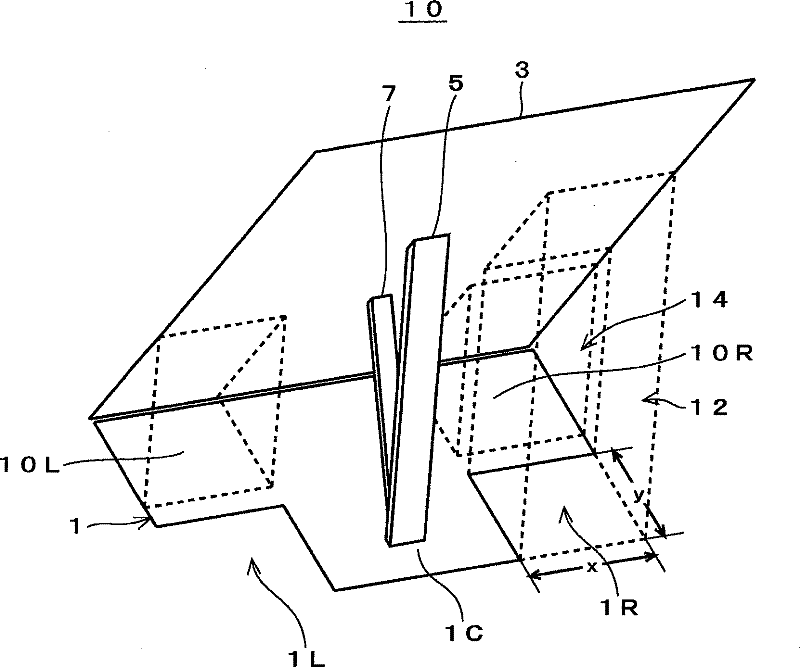

[0038] Embodiments of the present invention will be described below. figure 1 It is a conceptual configuration diagram showing an embodiment of the present invention. figure 1 It is a perspective view looking at the back side of the packaging container 10 toward the front side for easy understanding. From the long side 1 a of the base 1 , a rectangular back plate 3 is provided to stand obliquely upward at, for example, 58 degrees. Both corners of the opposite side 1b of the long side 1a are notched in a quadrangular shape to form bottom notched portions 1L, 1R.

[0039] In addition, a support 5 is vertically erected with the substantially center of the remaining bottom cut portion 1C as the lower end, and the upper end of the support 5 is fixed to the back surface of the back plate 3 to support the back plate 3 . In addition, the oblique support 7 is arranged from the approximate center of the bottom notch remaining portion 1C to support the approximate center of gravity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com