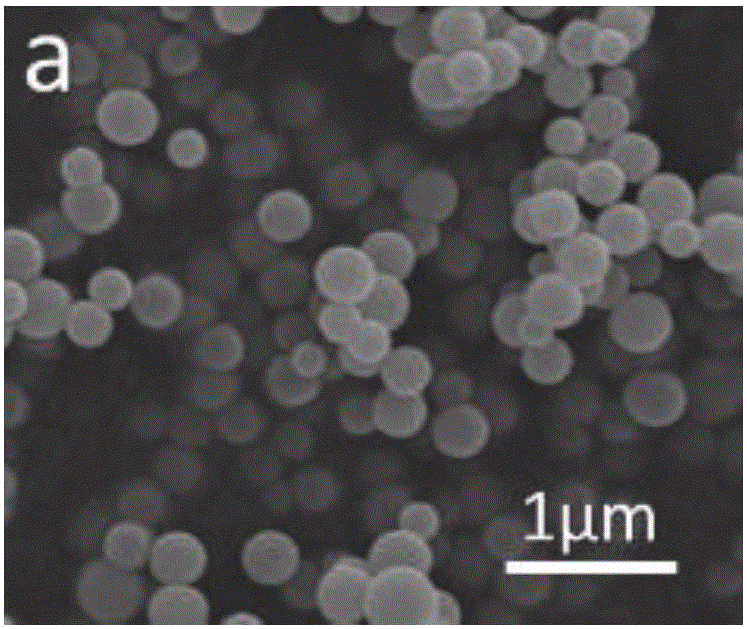

Nano lithium and sodium ion battery electrode material with bubble wrap structure and preparation method thereof

A sodium ion battery and electrode material technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of unsatisfactory battery performance and poor appearance, achieve good buffering effect, improve stability, and prolong cycle life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Bubble Wrap Structure Sn

[0090] 0.384g K 2 SnO 3 ·3H 2 O and 0.48g urea were dissolved in 80mL deionized water-dehydrated ethanol mixed solution (volume ratio 5: 3), and the solution obtained by mixing was stirred with a magnetic stirring device for 30min and then transferred to a Teflon-lined hydrothermal kettle. And insulated at 190°C for 10h in a blast drying oven, centrifuged the solution obtained after the reaction to obtain a white powder and dried at 60°C for 12h to obtain SnO 2 Precursor. Take the obtained SnO after drying 2 Dissolve 0.1g of the precursor in a mixed solution of 40mL deionized water and ethanol (volume ratio 3:1), add 0.2g glucose to the solution and ultrasonicate for 20 minutes, stir for 1h, then transfer the solution to 50mL Teflon Lined hydrothermal kettle, and kept in a blast drying oven at 190°C for 10h, and obtained brown powder by centrifugation. To form a carbon film, after drying, 0.2 g of the above brown powder was dissolved wit...

Embodiment 2

[0108] 0.392g (NH 4 ) 2 MoO 4 Dissolve 0.48g urea in 80mL deionized water-absolute ethanol mixed solution (volume ratio 5:3), stir the resulting solution with a magnetic stirring device for 30min, then transfer it to a Teflon-lined hydrothermal kettle, and Insulate at 190° C. for 10 h in a blast drying oven, centrifuge the solution obtained after the reaction to obtain a white powder, and dry at 60° C. for 12 h. Take the obtained MoO after drying 2 Dissolve 0.1g of the precursor in a mixed solution of 40mL deionized water and ethanol (volume ratio 3:1), add 0.2g glucose to the solution and ultrasonicate for 20 minutes, stir for 1h, then transfer the solution to 50mL Teflon Lined hydrothermal kettle, and kept in a blast drying oven at 190°C for 10h, and obtained brown powder by centrifugation. To form a carbon film, after drying, 0.2 g of the above brown powder was dissolved with 0.1 g of glucose and 6.7 g of sodium chloride in 50 mL of deionized water and sonicated for 30 ...

Embodiment 3

[0111] 0.464g GeCl 4 ·H 2 O and 0.56g urea were dissolved in 80mL deionized water-absolute ethanol mixed solution (volume ratio 5: 3), and the mixed solution was stirred with a magnetic stirring device for 30min and then transferred to a Teflon-lined hydrothermal kettle. And keep it warm at 190° C. for 10 h in a forced air drying oven, centrifuge the solution obtained after the reaction to obtain a white powder, and dry at 60° C. for 12 h. GeO obtained after drying 2 Dissolve 0.1g of the precursor in a mixed solution of 40mL deionized water and ethanol (volume ratio 3:1), add 0.2g glucose to the solution and ultrasonicate for 20 minutes, stir for 1h, then transfer the solution to 50mL Teflon Lined hydrothermal kettle, and kept in a blast drying oven at 190°C for 10h, and obtained brown powder by centrifugation. To form a carbon film, after drying, 0.2 g of the above brown powder was dissolved with 0.1 g of glucose and 6.7 g of sodium chloride in 50 mL of deionized water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com