Groove buffer of hydraulic cylinder

A hydraulic cylinder and buffer technology, applied in the field of hydraulic cylinder buffers, can solve the problems of large hydraulic impact and poor buffering effect, and achieve the effect of small hydraulic impact, simple structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

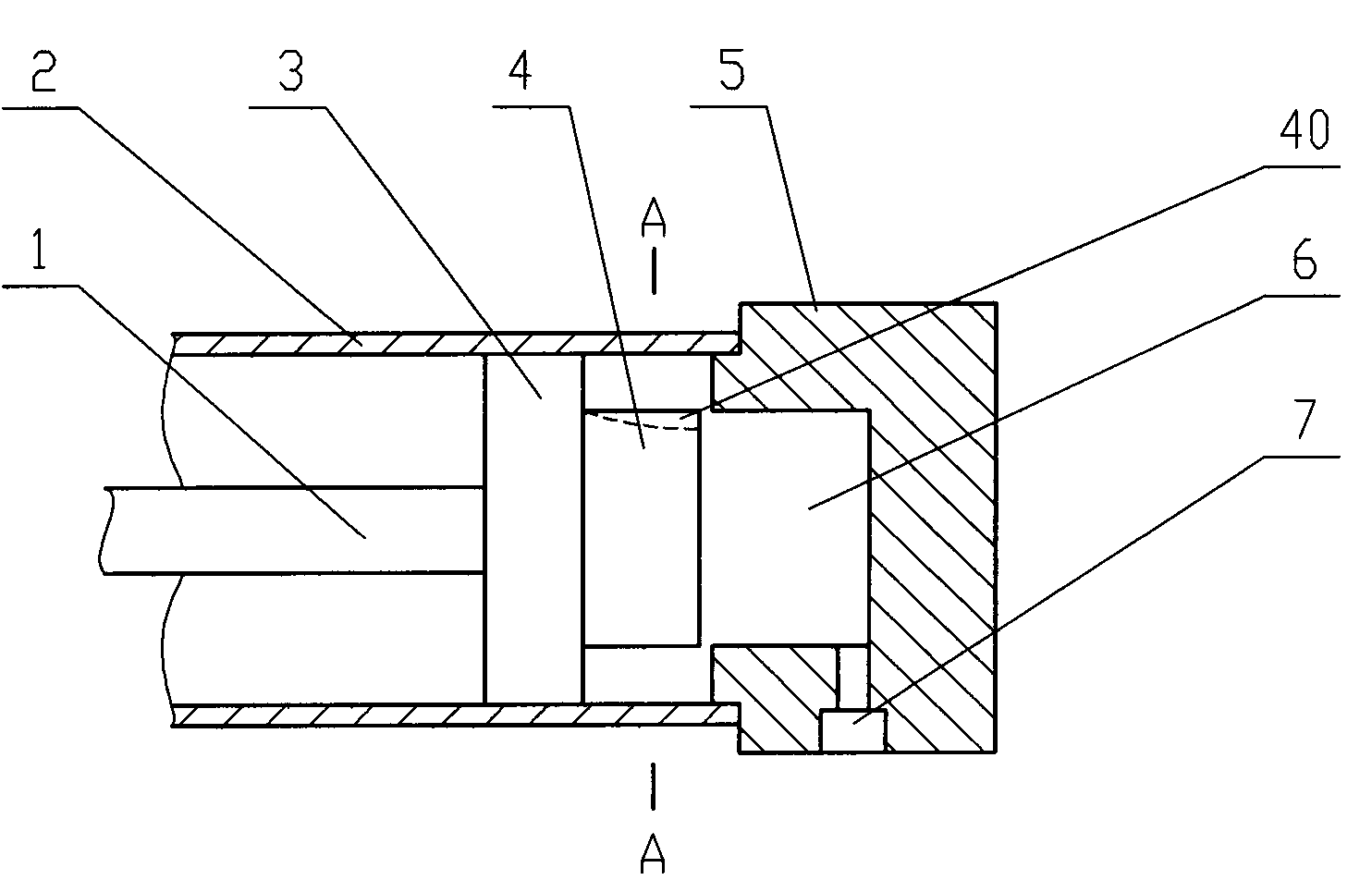

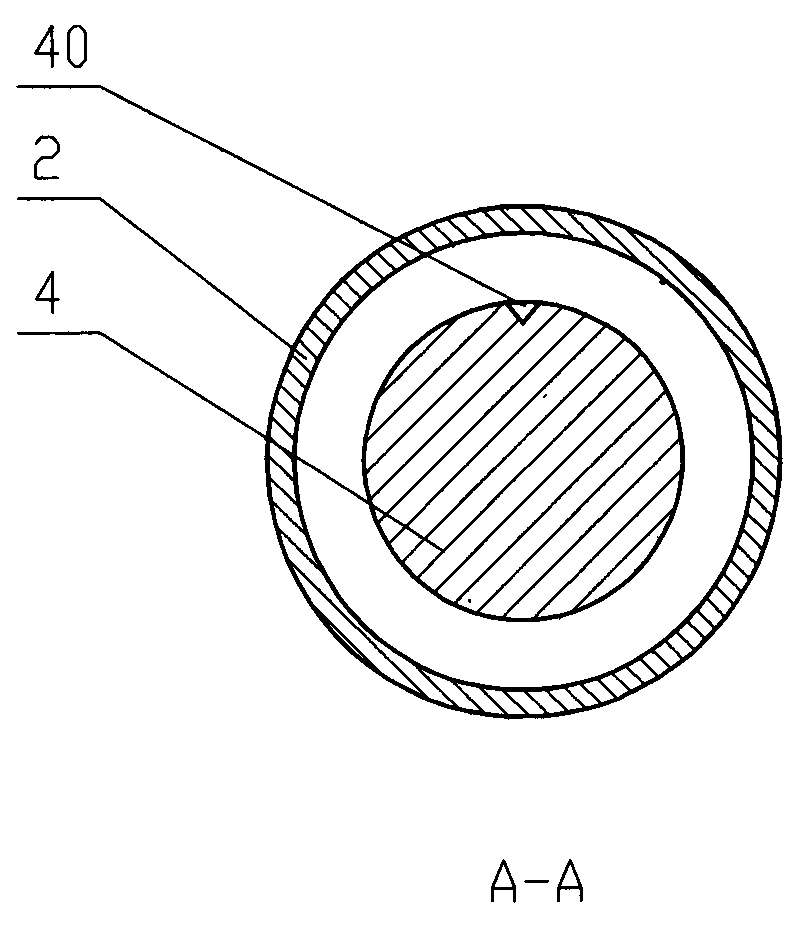

[0009] See figure 1 , figure 2 , the present invention comprises a hydraulic cylinder 2, a piston 3 and a cylinder cover 5 fixedly connected to the hydraulic cylinder 2, the piston 3 is fixedly connected to the plunger 1, the cylinder cover 5 has a cylindrical cavity 6 and an orifice 7, and the orifice 7 and the The cavity 6 is connected, the piston 3 is fixedly connected to the cylindrical buffer block 4, the outer diameter of the cylindrical buffer block 4 is slightly smaller than the inner diameter of the cavity 6, and the outer wall of the buffer block 4 has an arc-shaped groove 40 with a triangular cross section. The depth gradually increases towards the end of the buffer block 4 .

[0010] When the present invention works, when the plunger 1 moves toward the cylinder head 5 with the piston 3, after the buffer block 4 enters the cylindrical cavity 5, a buffer oil cavity is formed between the cavity 5 and the piston 3, and the sealed oil only It can flow out of the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com