Ultra-small-size optical fiber temperature sensing probe and preparation method thereof

An optical fiber temperature and sensing probe technology, applied in thermometers, thermometers with physical/chemical changes, measuring devices, etc., can solve the problems of low temperature sensing sensitivity, reducing the volume of optical fiber temperature sensing probes, and large probe volumes, etc. Achieve the effect of reducing the size of the probe, improving the temperature sensing sensitivity, and improving the temperature sensing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

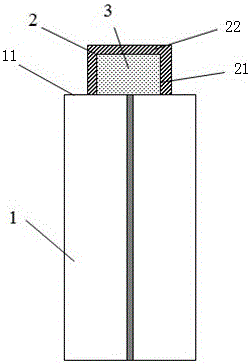

[0019] From figure 1 It can be seen from the figure that an ultra-small-volume optical fiber temperature sensing probe includes a single-mode optical fiber 1 and an ultra-small-volume cuboid sealed liquid chamber 2, and an SU-8 photoresist solution 3 is housed in the cuboid sealed liquid chamber 2, The cuboid sealed liquid chamber 2 is glued to the center of the end face 11 of the single-mode optical fiber, and its effective sensing area has a diameter of less than 50 microns and a length of less than 30 microns. Connect the fiber optic temperature sensing probe with a wide spectrum light source and a spectrometer through a fiber optic circulator, and the Fabry-Perot interference spectrum can be observed on the spectrometer, and the ambient temperature can be demodulated by monitoring the center wavelength of the interference peak on the spectrum, and the temperature sensing sensitivity Above 800 pm / ºC.

[0020] The single-mode optical fiber 1 of the present invention is a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com