Pump turning direction hydraulically-started reversible water turbine and work method thereof

A water turbine and hydraulic technology, applied in hydroelectric power generation, engine components, machines/engines, etc., can solve the problems of expensive equipment, complicated operation, and large space occupied by equipment, and achieve the effect of preventing flyaway and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

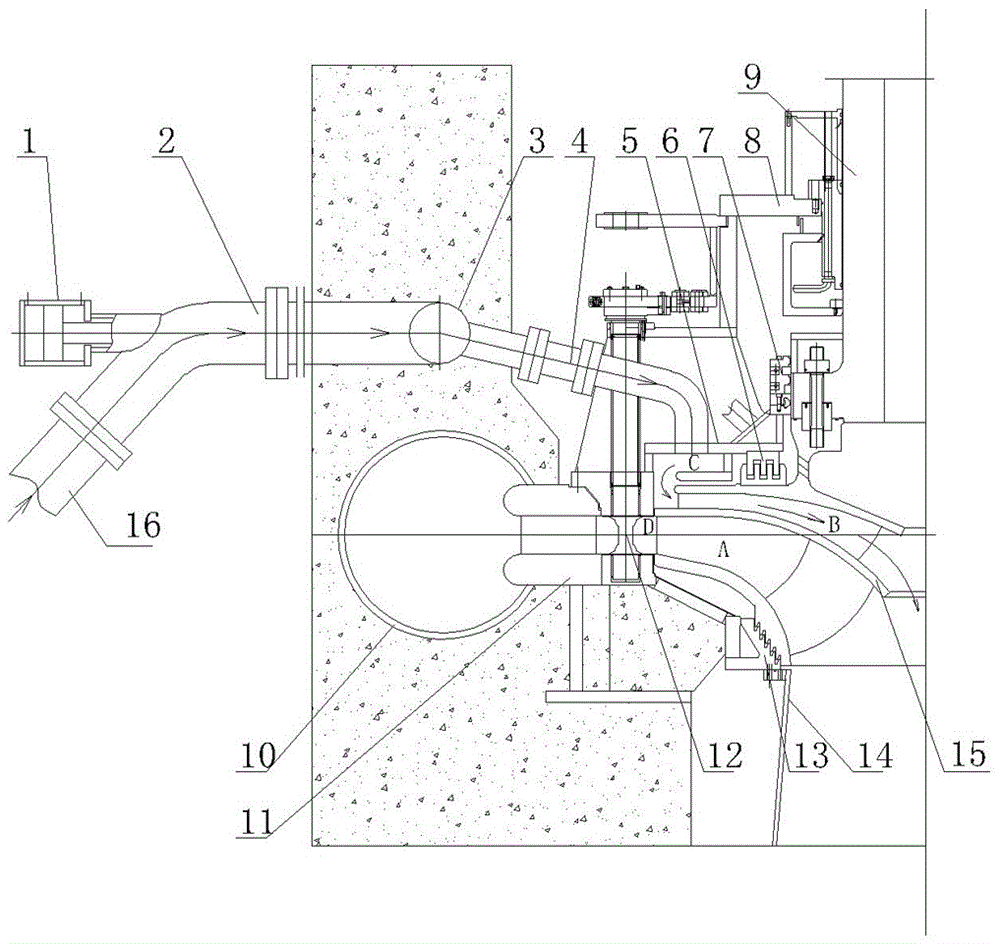

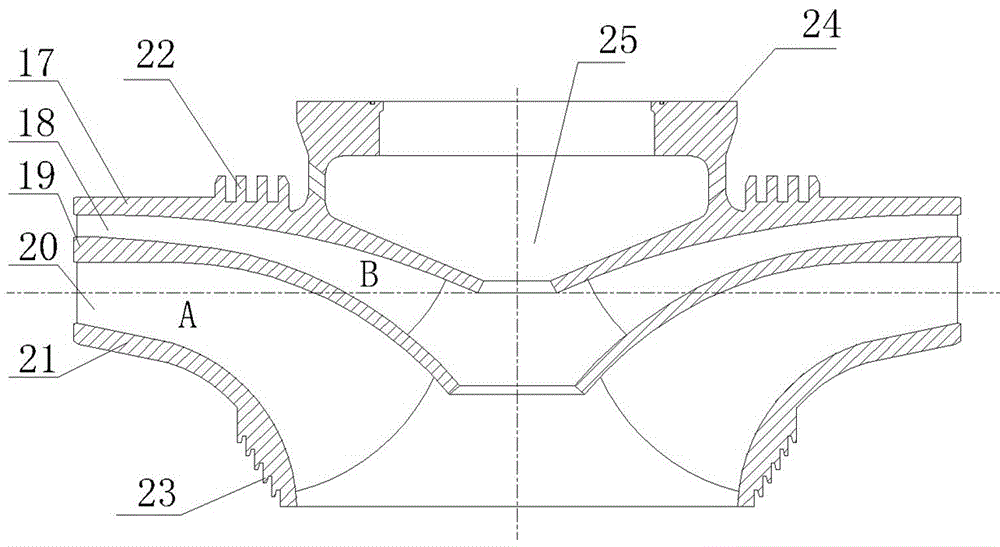

[0026] Such as figure 1 As shown in the figure, a reversible water turbine with hydraulic start in the direction of rotation of the pump includes a needle valve operating device 1, a needle valve 2, a ring pipe 3, an expansion joint 4, a top cover 5, an upper fixed leak-proof ring 6, a main shaft seal 7, water Guide bearing 8, main shaft 9, volute 10, seat ring 11, movable guide vane 12, lower fixed leak-proof ring 13, draft tube 14, runner 15.

[0027] The diversion pipe before the needle valve 2 is connected to the pressure steel pipe 16 behind the water inlet valve of the unit, the water pipe behind the needle valve 2 is connected to the ring pipe 3, the needle valve 2 is opened and closed by the needle valve operating device, and the ring pipe 3 is connected to multiple Two te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com