Efficient dust removal system for sea sedge product dusting and dust removal method thereof

A technology of dust removal system and products, which is applied in the fields of dust removal, food coating, chemical instruments and methods, etc. It can solve the problems of physical impact of operators, impact of light and small powder on the environment, and inability to collect light and small powder in a centralized manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

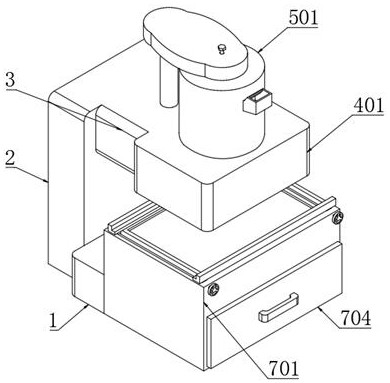

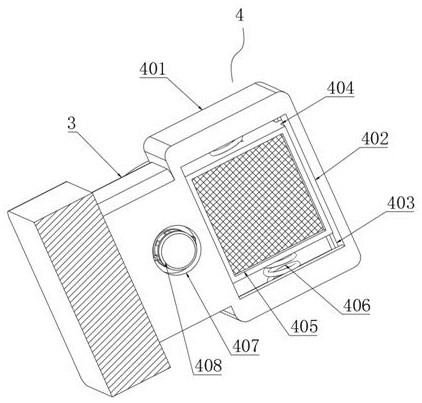

[0050] Embodiment 1: as Figure 1-8 As shown, the present invention provides a technical solution, a high-efficiency dust removal system for dusting seaweed products, including a base 1, one end of the base 1 is fixedly connected to a support column 2, one end of the support column 2 is fixedly connected to a horizontal plate 3, and the horizontal plate 3 One end is fixedly connected with a powder spreading mechanism 4, and the top of the powder spreading mechanism 4 is fixedly connected with a stirring mechanism 5;

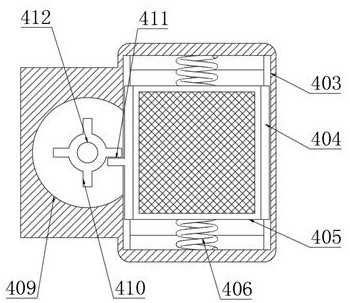

[0051] The powder spreading mechanism 4 includes a vibration box 401, a powder outlet trough 402, a chute 403, a slide plate 404, a sieve bucket 405, a support spring 406, a circular groove 407, a rotating motor 408, a rotating chamber 409, a cross rotating plate 410, and a pushing block 411 and turning rod 412;

[0052] One end of the horizontal plate 3 is fixedly connected with a vibrating box 401, the bottom of the vibrating box 401 is provided with a powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com