A kind of flocking device and using method of screen printing process

A technology of screen printing and flocking, which is applied to screen printing machines, devices for coating liquid on the surface, printing, etc., can solve the problems of low efficiency of multi-color or multi-pattern flocking, achieve low production costs, and improve Flocking efficiency, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

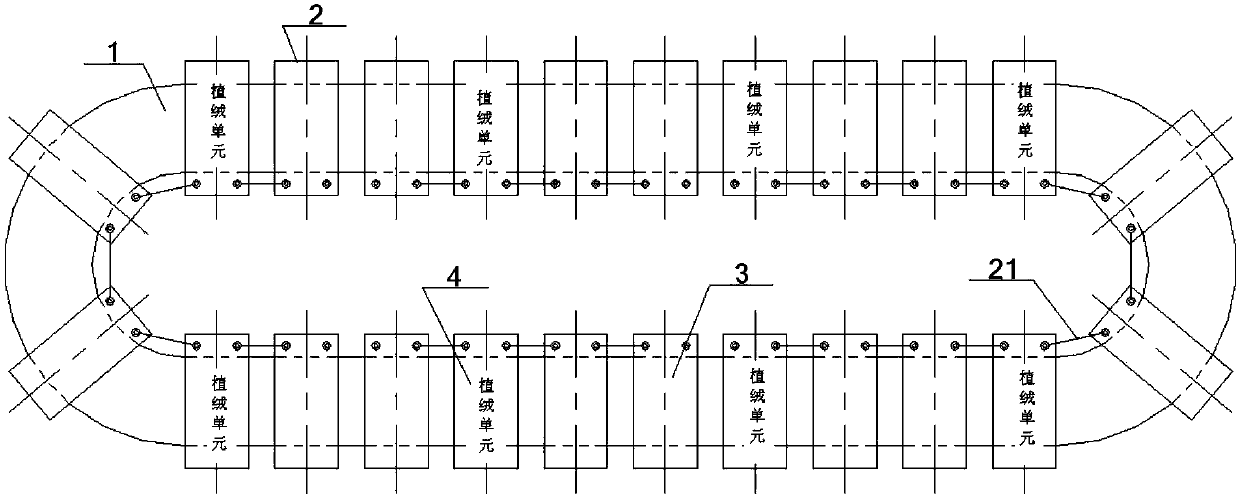

[0055] see figure 1 – Figure 4, a kind of flocking device of silk screen printing process, comprising a conveyor belt 1 and a plurality of platens 2 arranged on it, the conveyor belt 1 is a closed ring, and all the platens 2 are arranged along the conveyor belt 1 layout, And be provided with screen printing unit 3 on platen 2; Described flocking device also comprises the flocking unit 4 that is arranged on platen 2, only is provided with a silk screen printing unit 3 or one on each platen 2 Flocking unit 4 ; the number of screen printing units 3 and flocking units 4 is at least two, and the sum of the numbers of screen printing units 3 and flocking units 4 is equal to the number of platens 2 . The flocking device also includes a plurality of connecting rods 21 , and adjacent platens 2 are connected through the connecting rods 21 .

[0056] A method for using the flocking device of the above-mentioned screen printing process, the method for using includes the following steps...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

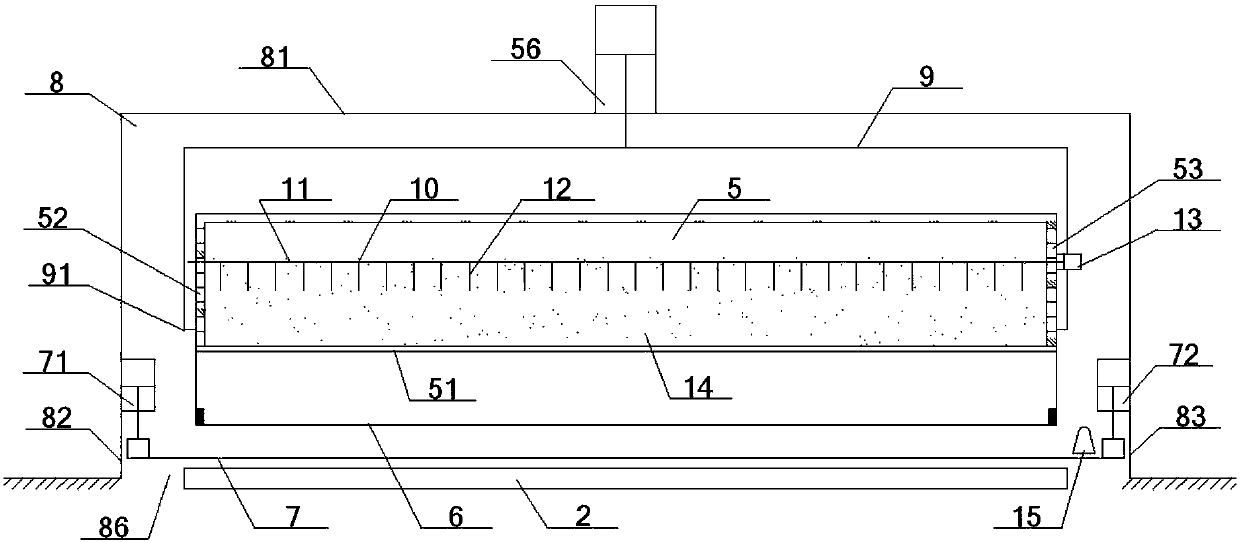

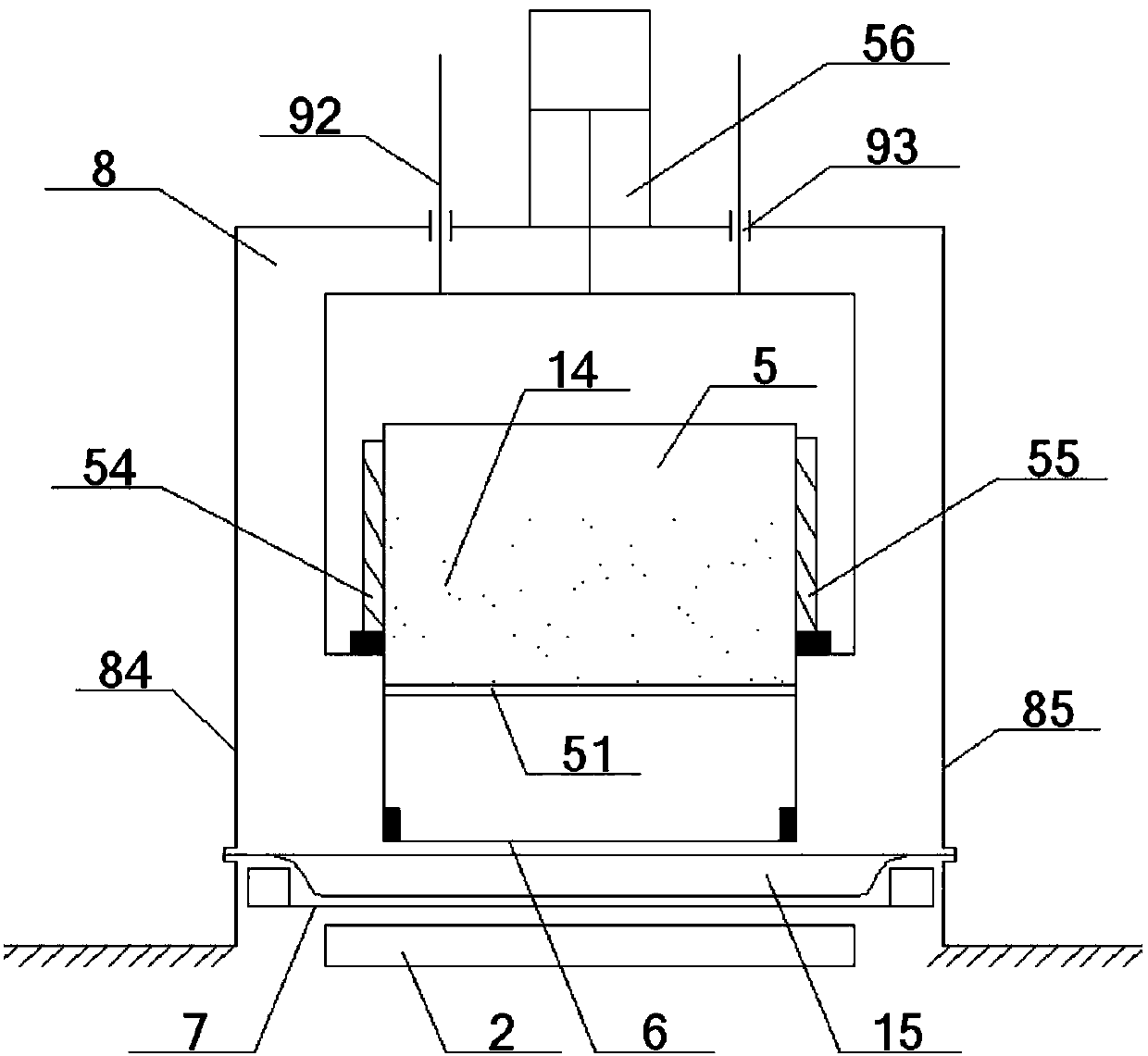

[0059] Described flocking unit 4 comprises support case 8 and the cashmere case 5 that is provided with inside thereof, positive grid 6, screen frame 7; Plate 83, front side plate 84, rear side plate 85, the bottom surface of described supporting top plate 81 is connected with the top edge of left side plate 82, right side plate 83, front side plate 84, rear side plate 85, left side plate 82 , the side of the rear side plate 85, the right side plate 83, and the front side plate 84 are connected successively to form a closed structure, and the bottom edges of the left side plate 82, the right side plate 83, the front side plate 84, and the rear side plate 85 form a An opening 86, which is arranged opposite to the platen 2 directly below it; the material of the velvet box 5 is transparent plastic, and the velvet box 5 is a one-way opening structure, and the bottom opening of the velvet box 5 is connected to t...

Embodiment 3

[0063] Basic content is the same as embodiment 2, the difference is:

[0064] A velvet recovery device 15 is arranged on the screen frame 7 near the junction of the screen frame 7 and the right screen frame lifting cylinder 72 .

[0065] After the flocking on each flocking unit 4 is completed, the remaining fluff 14 falling on the screen frame 7 is reclaimed by the velvet reclaimer 15. After recycling, first promote the velvet box 5, and then promote the screen frame 7 to prepare Flocking next time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com