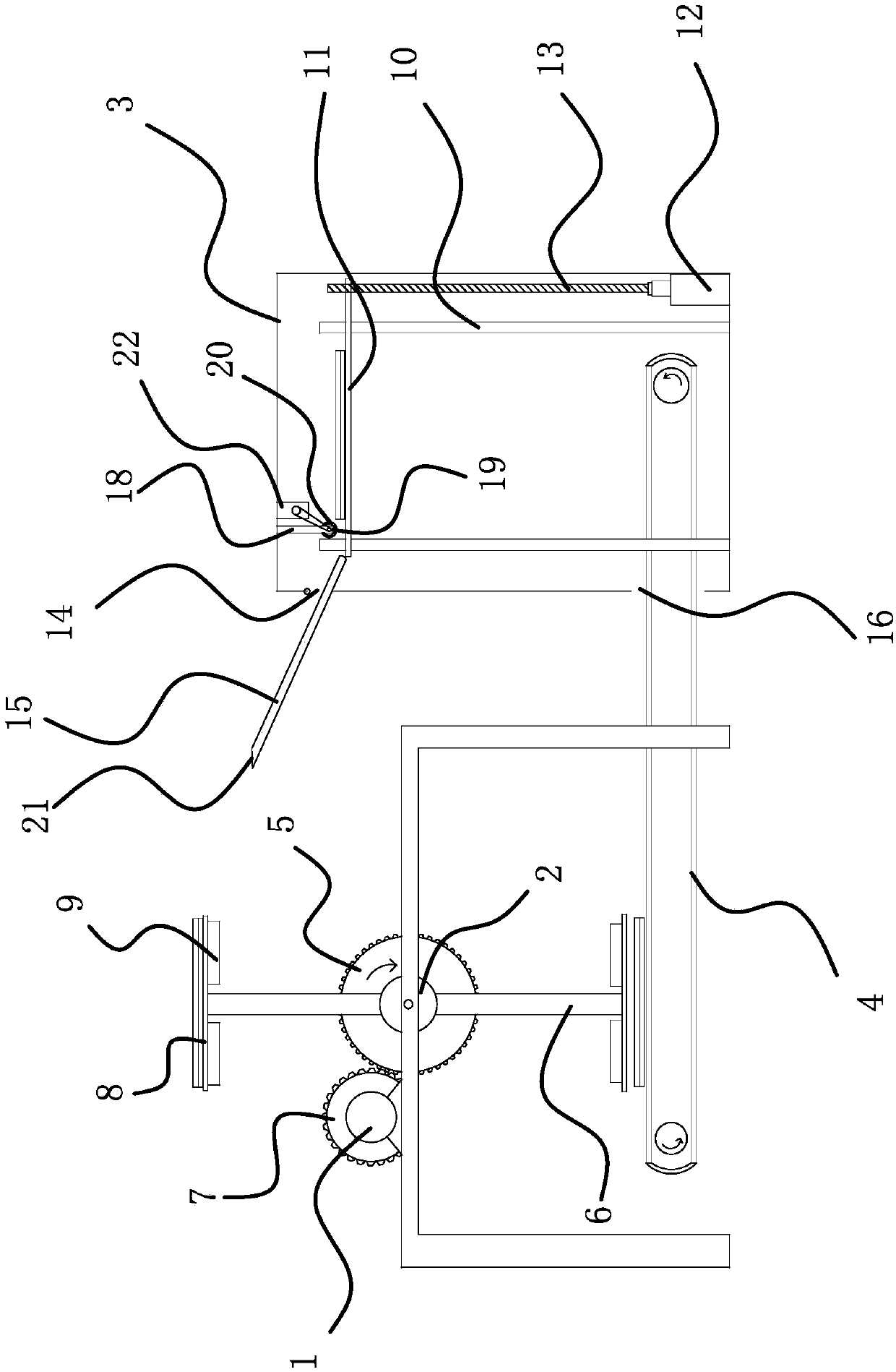

Iron frame reversing mechanism of double-faced flocking integrated machine

An all-in-one machine and frame technology, applied in the field of flocking, can solve the problems of low degree of automation, long time, not suitable for double-sided flocking, etc., and achieve the effect of high degree of automation, short process flow, and improved flocking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

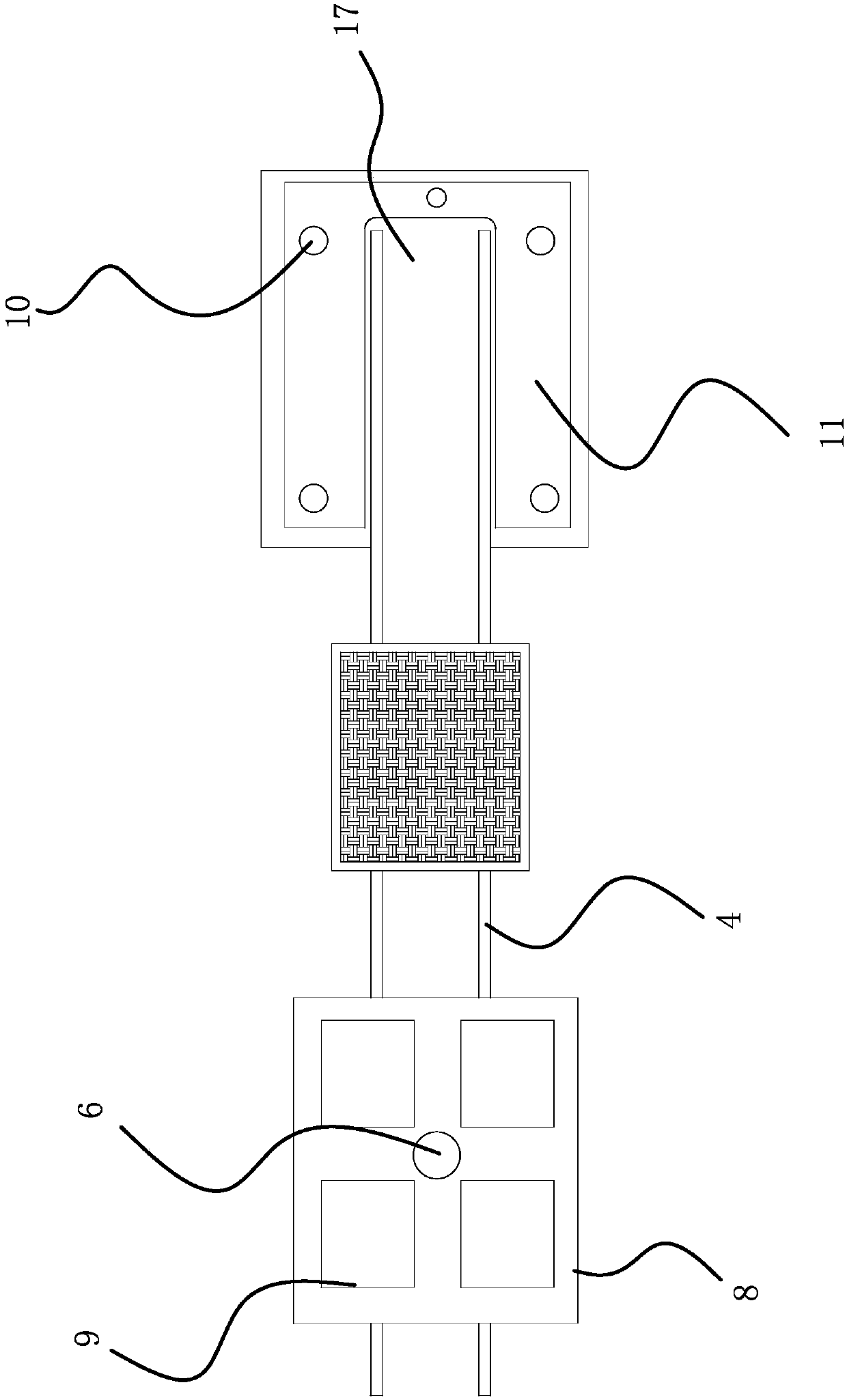

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0020] Such as figure 1 , figure 2 As shown, an iron frame turning mechanism of a double-sided flocking integrated machine includes a turning motor 1 fixed on the frame, a turntable 2 connected to the frame by vertical rotation, a lifting box 3 and a conveyor belt 4, Rotating gear 5 and fork 6 that rotate synchronously are fixed on the turntable 2, and the output shaft of turning over motor 1 is sheathed with the main gear 7 that meshes with rotating gear 5, fork 6 has two and is in symmetrical setting, and fork 6. The outer end is vertically connected with an adsorption plate 8 that can absorb the iron frame. Some electromagnets 9 are fixed on the inside of the adsorption plate 8. The lifting box 3 is arranged on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com