High-temperature titanium alloy rod with excellent comprehensive performance and preparation process thereof

A high-temperature titanium alloy and alloy technology, applied in the field of titanium-based alloys, can solve the problems of unstable alloy surface, unstable structure, and increased probability of brittle phase precipitation, and achieve excellent high-temperature comprehensive performance, excellent service performance, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of high-temperature titanium alloys: raw materials are sponge titanium, high-purity aluminum, sponge zirconium, silicon particles, and Ti-Nb, Ti-Sn, Ti-Ta, Al-Mo, Al-Er master alloys, proportioned and mixed according to the ingredients Evenly clad with alloy, and pressed into electrodes on a press. The electrode is smelted on a vacuum consumable electrode electric arc furnace, and the titanium alloy ingot is obtained by three times of remelting, and the ingot is descaled, and the head and tail are removed.

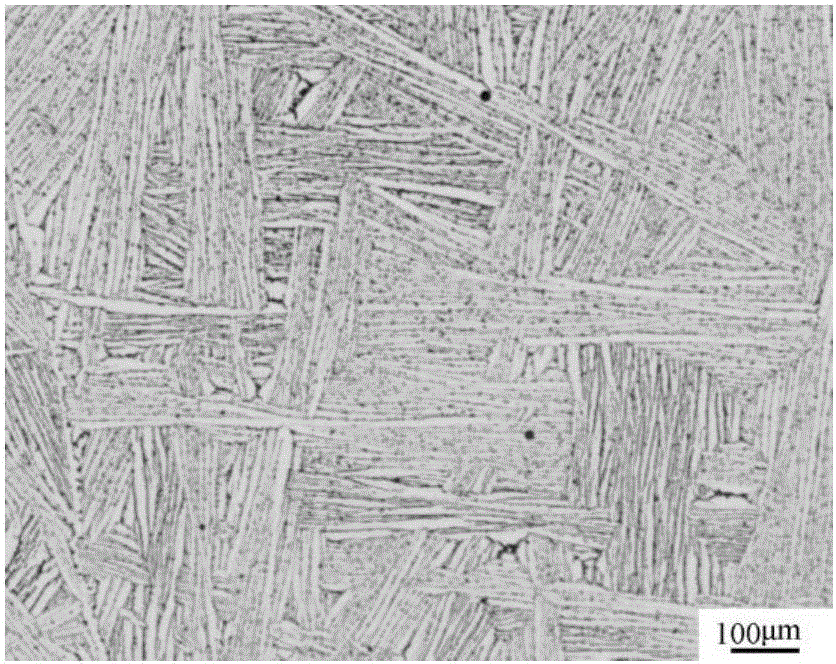

[0025] The alloy ingot structure after smelting is shown in the attached figure 1 , it can be seen that the obtained ingot structure is the typical Widmanstatten structure in titanium alloy, the grain size is large, and a large bundle is formed in the original β grain, and there are many α sheets parallel to each other in the same bundle. form the same orientation.

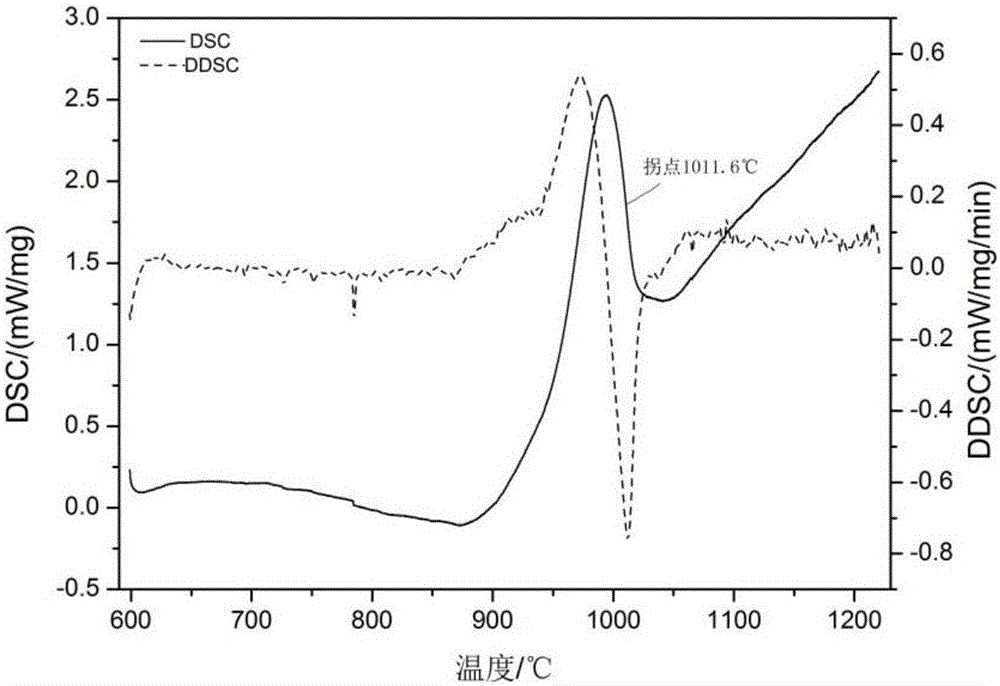

[0026] In order to determine the alloy forging process, the present invention adopts t...

Embodiment 1

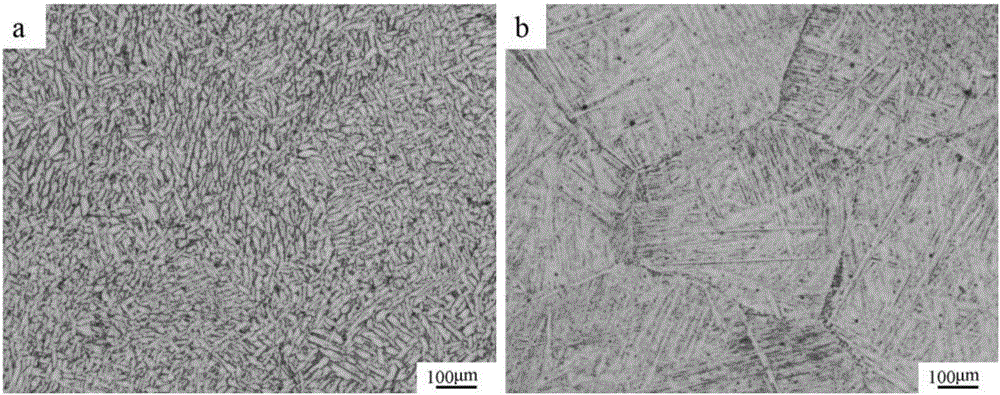

[0029] Alloy raw materials are prepared according to the nominal composition Ti-6.0Al-3.0Sn-5.0Zr-0.5Mo-1.0Ta-0.4Si-0.2Er (weight percent, %), and the raw materials use sponge titanium, high-purity aluminum, sponge zirconium, silicon particles and Ti-Nb, Ti-Sn, Ti-Ta, Al-Mo, Al-Er master alloys are proportioned according to the ingredients and mixed evenly to clad the alloy, and pressed on a press to form electrodes. The electrode is smelted on a vacuum consumable electrode electric arc furnace, and three times of remelting are carried out to obtain titanium alloy ingots. After the ingots are peeled off, glass protective lubricants are applied to prevent the alloys from being oxidized at high temperatures. Open billet forging at 1150°C. After open billet forging, a square bar with a side length of 50 mm is obtained. Then, it is subjected to multiple fire pier drawing at 1000 °C to refine the structure. Finally, it is precision forged into a round bar with a diameter of Φ30 mm. ...

Embodiment 2

[0036] Alloy raw materials are prepared according to the nominal composition Ti-6.0Al-3.0Sn-5.0Zr-0.5Mo-1.0Ta-0.4Si-0.2Er (weight percent, %), and the raw materials use sponge titanium, high-purity aluminum, sponge zirconium, silicon particles and Ti-Nb, Ti-Sn, Ti-Ta, Al-Mo, Al-Er master alloys are proportioned according to the ingredients and mixed evenly to clad the alloy, and pressed on a press to form electrodes. The electrode is smelted on a vacuum consumable electrode electric arc furnace, and three times of remelting are carried out to obtain titanium alloy ingots. After the ingots are peeled off, glass protective lubricants are applied to prevent the alloys from being oxidized at high temperatures. Open billet forging at 1150°C. After open billet forging, a square bar with a side length of 50 mm is obtained. Then, multiple fire pier drawing is carried out at 1050 °C to refine the structure. Finally, a round bar with a diameter of Φ30 mm is precision forged.

[0037] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com