Method for flocculating microalgae by using flue gas and application thereof

A microalgae and flue gas technology, which is applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of high cost of using organic polymer flocculants, affecting the subsequent production of microalgae energy, and huge amount of flocculants, etc. problems, to achieve the effect of reducing the cost of separation and recovery, high efficiency of flocculation and separation, and eliminating the need for stirring operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

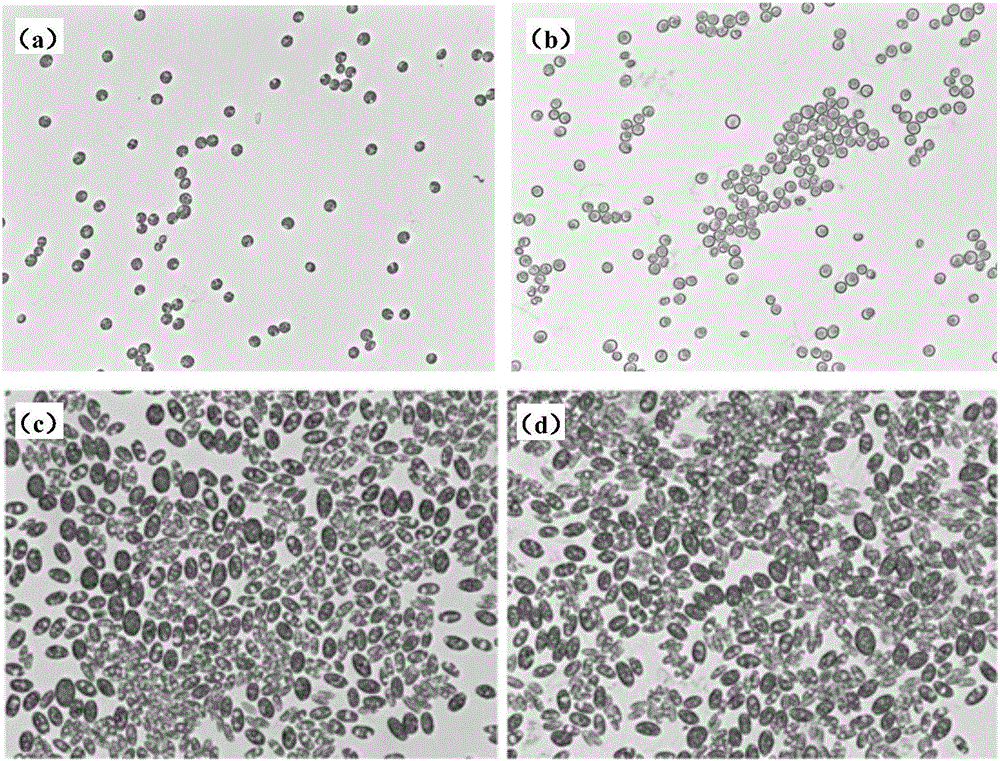

[0039] Example 1: Flocculation of Scenedesmus obliquus

[0040] Scenedesmus obliquus (Scenedesmus obliquus, purchased from the Algae Collection Center, University of Texas at Austin, USA) was cultivated in the incubator with conventional BG-11 culture medium. Take 2LBG-11 culture solution for cultivation, and adjust the microalgae implantation amount to OD 750 ≈0.6, at a temperature of 25°C, with an average light intensity of 200μmol·m -2 ·s -1 Cool white fluorescent light for 24 hours, and continuously pass through the air containing 1% CO 2 (v / v) of air. The cultivation time is 16 days as a cycle.

[0041] When the dry weight of Scenedesmus obliquus in the culture medium is 1.0-6.0g / L, the flue gas containing 1000ppm sulfur dioxide is passed into the microalgae culture medium until obvious flocs are produced, and the aeration is stopped after about 35-50 minutes (the aeration time depends on the dryness). Weight increases), naturally settled for 30 minutes, poured out t...

Embodiment 2

[0044] Example 2: Flocculation of Scenedesmus sp

[0045] Scenedesmus sp (Scenedesmus sp, purchased from the Algae Collection Center, University of Texas at Austin, USA) was cultivated in the incubator with BG-11 culture medium. Measure 2L of BG-11 culture solution for cultivation, the amount of microalgae implantation, cultivation conditions and cultivation time are the same as in Example 1.

[0046] When the dry weight of Scenedesmus sp in the culture medium is 1.0-6.0g / L, pass the flue gas containing 800ppm sulfur dioxide into the microalgae culture medium until obvious flocs are produced, and stop the aeration after about 50-70 minutes (the aeration time is based on the dry weight increase with increasing), natural sedimentation for 30min, pour out the supernatant, and Scenedesmus sp can be obtained. Calculated by the above formula, the separation rate after standing for 30 minutes was 92.3-98.2%.

Embodiment 3

[0047] Example 3: Flocculation of Chlorococcus ellipsoides

[0048] Chlorococcum ellipsoideum (Chlorococcum ellipsoideum, purchased from the Algae Collection Center, University of Texas at Austin, USA) was cultivated in the incubator with BG-11 culture medium. Measure 2L of BG-11 culture solution for cultivation, the amount of microalgae implantation, cultivation conditions and cultivation time are the same as in Example 1.

[0049] When the dry weight of Chlorococcus ellipsoides in the culture solution is 1.0-6.0g / L, the flue gas containing 600ppm sulfur dioxide is passed into the microalgae culture solution until obvious flocs are produced, and the aeration is stopped after about 80-100 minutes (the aeration time depends on dry weight increases), naturally settle for 30 minutes, pour out the supernatant, and then get Pidelodioides. Calculated by the above formula, the separation rate after standing for 30 minutes was 90.34-91.90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com