Flax cellulose-based phosphorus expansion type flame retardant and preparation method and application thereof

A technology of intumescent flame retardant and flax fiber, which is applied in the field of flax cellulose-based phosphorus-based intumescent flame retardant and its preparation, can solve the problems of high destructiveness of cellulose, leftover by-products, complicated process, etc., and achieve synergy High flame retardant efficiency, uniform and dense carbon layer structure, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

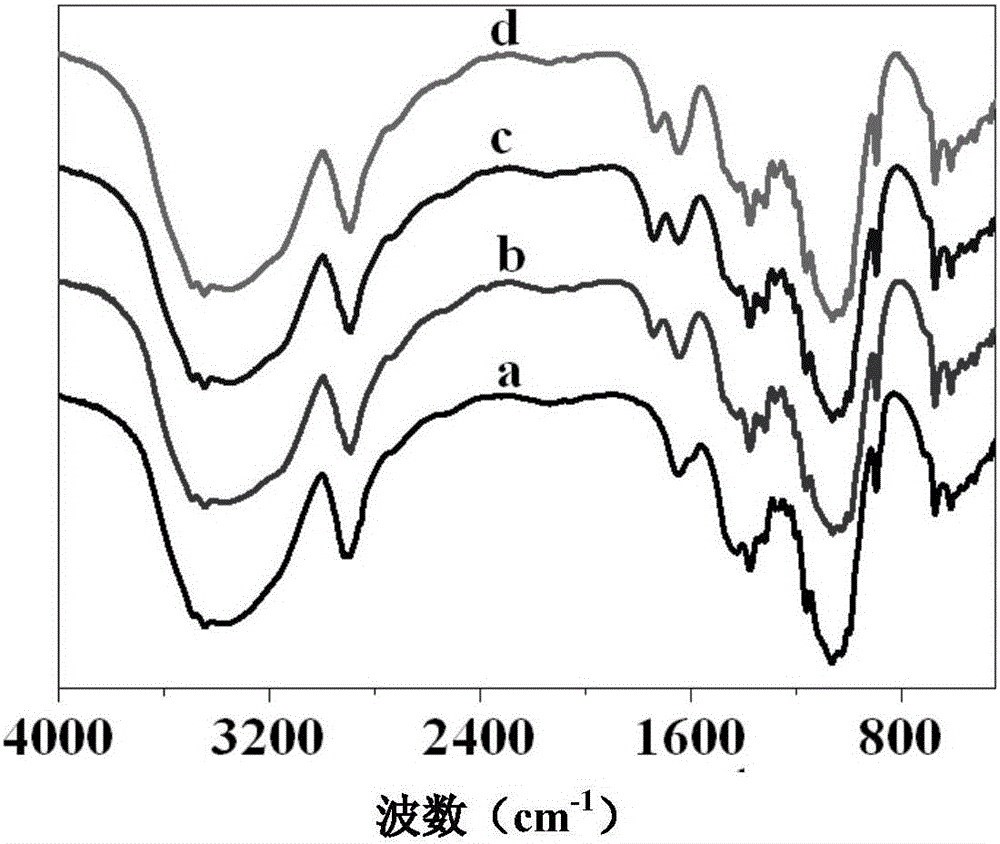

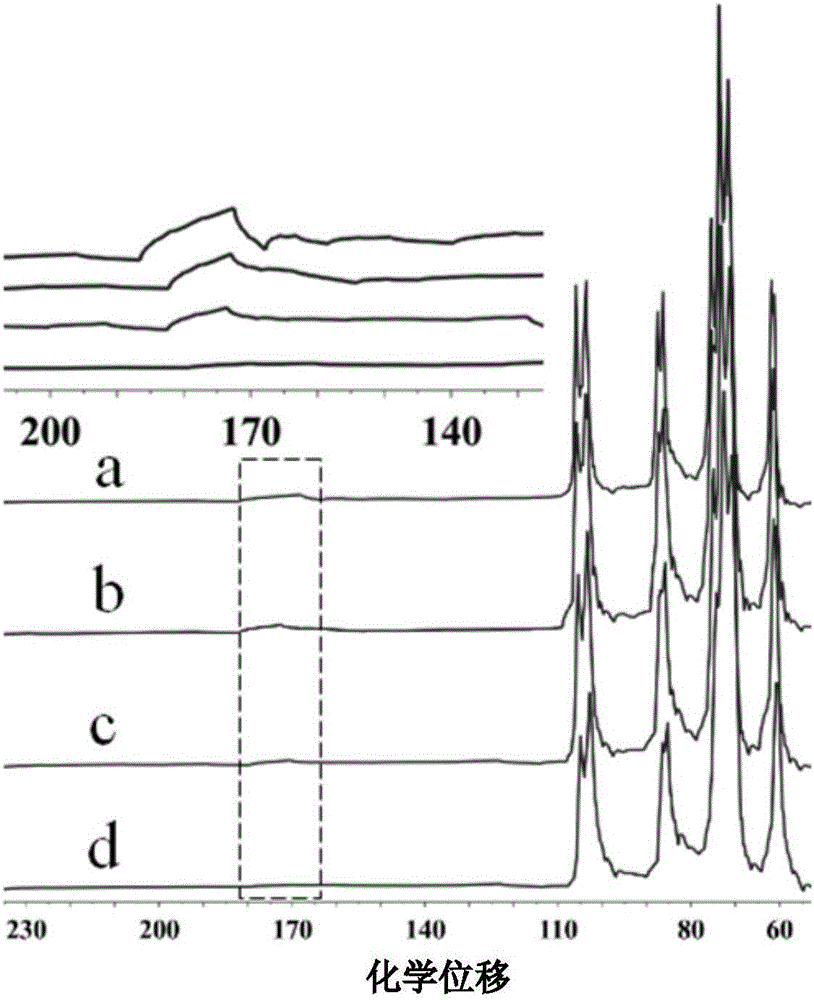

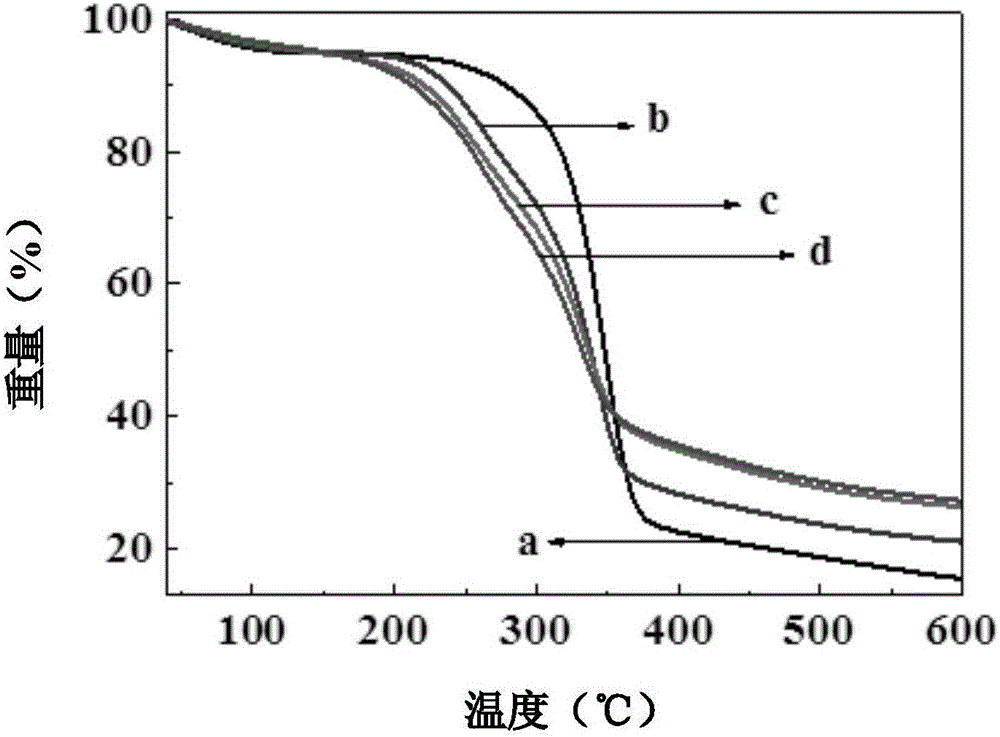

Embodiment 1

[0052] Soak 100 parts of flax fiber in 1500 parts of distilled water, and drop in pre-configured 0.1mol / L CuSO 4 Solution 2 parts, slowly add 24.6 parts of hydrogen peroxide (H 2 o 2 Content 30%) solution, placed in 30 DEG C constant temperature stirring reaction for 72 hours, suction filtered and washed with distilled water carboxy flax fiber, put into 80 DEG C drying box and dry for 12 hours. After taking it out, it was pulverized with a high-speed mixer for 6 minutes to obtain a solid product. The carboxyl content was measured to be about 12.6% by titration method, and the marked sample was OLF12.6.

Embodiment 2

[0054] Soak 100 parts of flax fibers in 1500 parts of distilled water, drop in the pre-configured 0.05mol / L FeCl 2 Solution 3 parts, slowly add 48.6 parts of hydrogen peroxide (H 2 o 2 Content 30%) solution, placed in 35 ℃ constant temperature stirring reaction for 60 hours, suction filtered and washed with distilled water carboxy flax fiber, put into 85 ℃ drying box to dry for 12 hours. After taking out, the fiber was pulverized with a high-speed mixer for 6 minutes to obtain a solid product. The carboxyl content was measured to be about 27.4% by titration method, and the marked sample was OLF27.4.

Embodiment 3

[0056] Soak 100 parts of flax fiber in 1500 parts of distilled water, drop in the pre-configured 0.05mol / L CoCl 2 Solution 3 parts, slowly add 50.9 parts of hydrogen peroxide (H 2 o 2 Content 30%) solution, placed in 40 ° C constant temperature stirring reaction for 70 hours, will be suction filtered and washed with distilled water carboxy flax fiber, put into 85 ° C drying oven to dry for 12 hours. After taking it out, the fiber was pulverized with a high-speed mixer for 6 minutes to obtain a solid product. The carboxyl content was measured to be about 28.4% by titration method, and the marked sample was OLF28.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com